You’ve had your fair share of good times on the water with your trusty boat, haven’t you? But like any other mechanical object, sometimes things go wrong, and the outboard motor decides it’s time to stutter or quit. You’ve never ventured into this side of the boating world before, but with the “Beginner’s Guide To Outboard Motor Repair”, it’s time to get your hands dirty. This handy guide will serve as your companion, providing step-by-step procedures and practical tips to restore your outboard motor back to health – and you back to those tranquil waters you love.

Understanding Outboard Motors

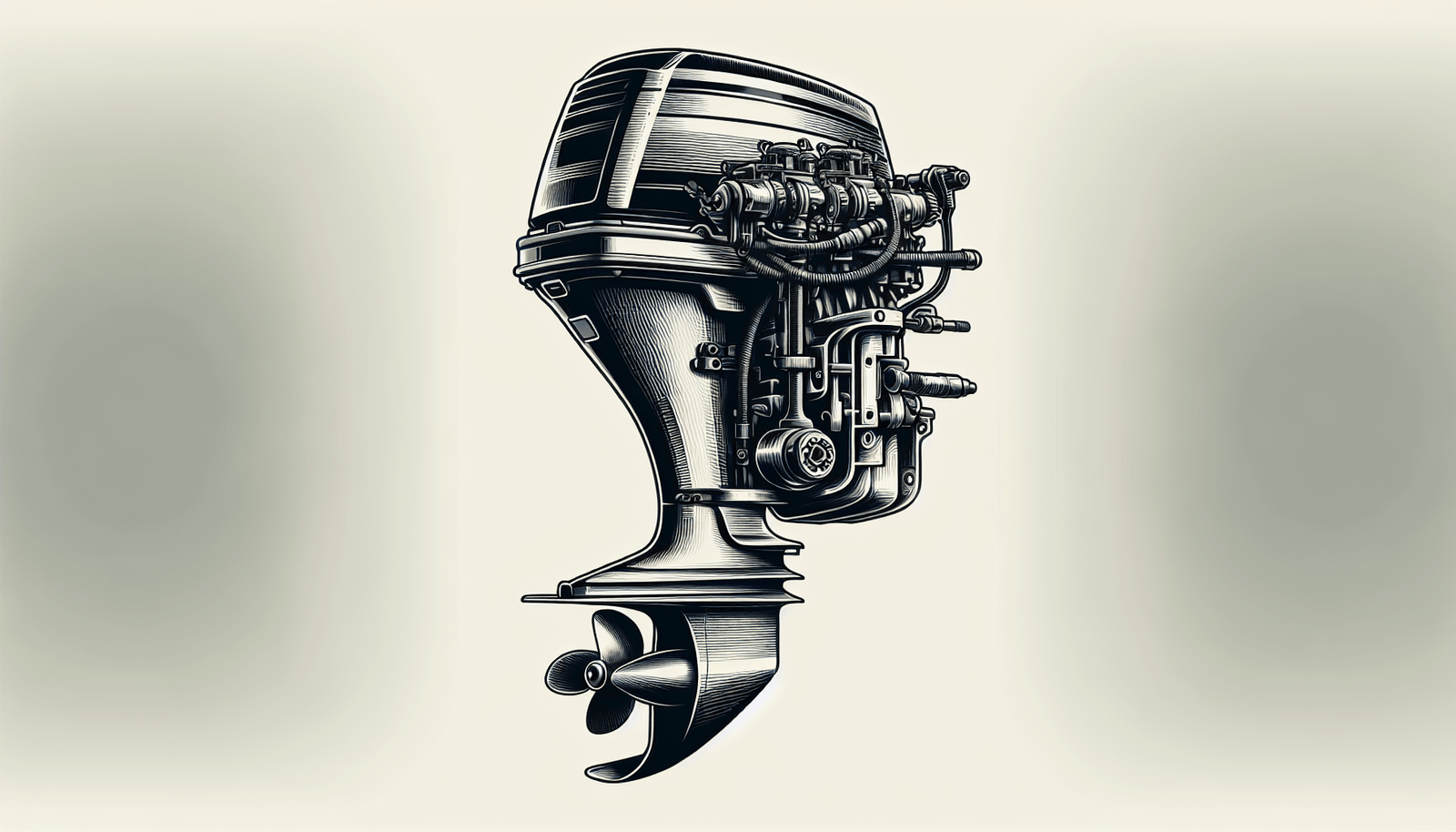

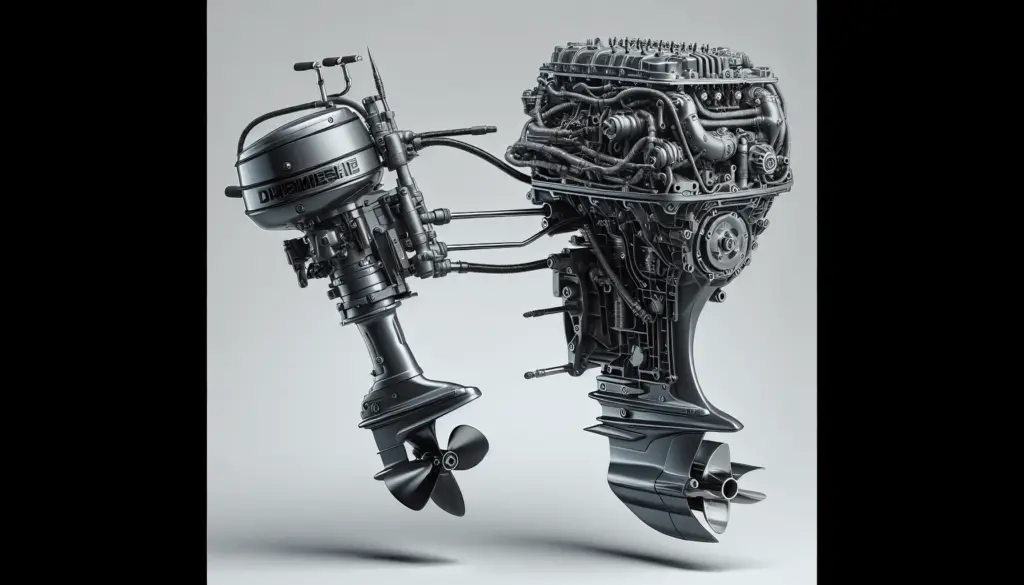

Outboard motors are the driving force behind many types of boats, from fishing vessels to leisure crafts. Specially designed for marine use, they consist of a self-contained unit that includes an engine, gearbox, and propeller. Understanding how these parts work together will help you confidently carry out essential maintenance tasks and troubleshoot issues more effectively.

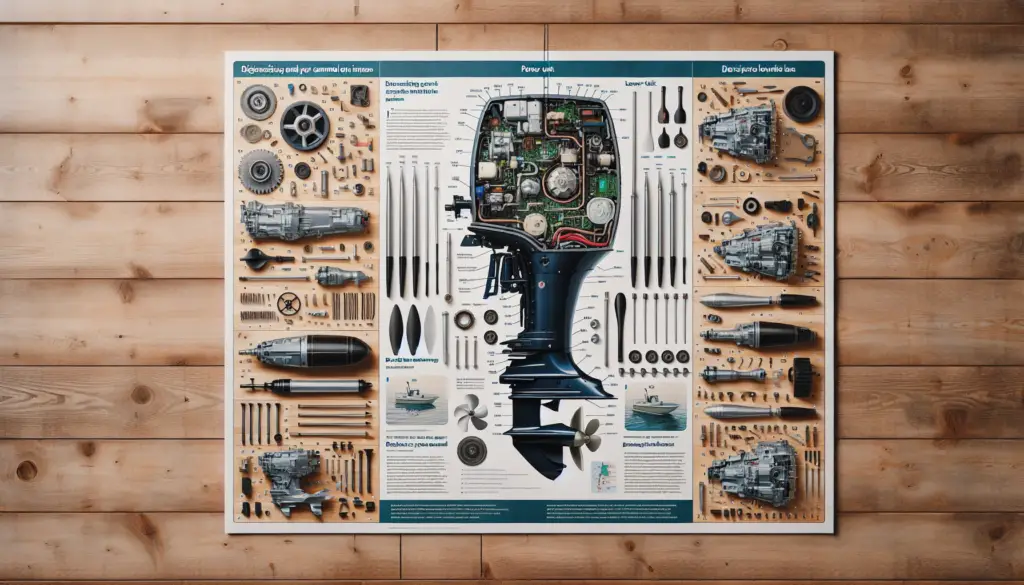

Parts of an Outboard Motor

Your outboard motor comprises several key parts. The powerhead includes the engine and gearbox. The combustion process occurs here, driving the pistons and turning the crankshaft. The gearbox transmits this power to the propeller, which moves your boat through the water. The motor also has a tiller for steering and a throttle for controlling speed. Lastly, the cowl protects the engine from water, debris and the elements.

How an Outboard Motor Works

Outboard motors operate on a simple principle. Spark plugs ignite the fuel/air mixture, causing a mini explosion within the cylinder. This drives the piston down, turning the crankshaft. The gearbox then translates this rotary motion to the propeller, pushing water past it and thrusting the boat forward. Key controls include the throttle for speed regulation and a steering mechanism for navigation.

Types of Outboard Motors

There are two main types of outboard motors – two-stroke and four-stroke. The two-stroke engine completes its power cycle in two movements of the piston (one up, one down), while the four-stroke engine does it in four (up, down, up, down). Generally, four-stroke engines are more fuel-efficient and environmentally friendly but are also heavier and more complex. Your choice will depend on your needs, constraints, and personal preferences.

Basic Motor Troubleshooting

When you’re out on the water, understanding basic motor troubleshooting can be a lifesaver. Often, problems start small and escalate if left unchecked. Knowing how to identify and address common issues can prevent major headaches and costly repairs.

Identifying Common Problems

Common problems with outboard motors include poor performance, difficulty starting, overheating, and unusual noises or vibrations. Identifying these symptoms early enough can prevent more serious issues from developing. Keeping a regular check on your motor conditions will ensure it remains in good health.

Basic Outboard Motor Troubleshooting Techniques

Basic troubleshooting involves checking the main components – fuel, spark, and compression. If your motor isn’t starting or is running poorly, these are good places to begin. Check for fuel contamination or blockages, ensure your spark plugs are firing correctly, and conduct a compression test to rule out any cylinder issues.

When to Call a Professional

While many minor issues can be dealt with independently, there are times when professional help is necessary. Persistent problems, major mechanical failures, and tasks beyond your skill level all require a trained technician. If a solution isn’t clear after basic troubleshooting, then it’s time to call a pro.

Tools for Outboard Motor Repair

Just like any machine, outboard motors require the right tools for repair and troubleshooting. Having the essential tools on hand will make your tasks easier and more efficient.

Essential Tools

You don’t need a vast array of specialty tools for most outboard motor repairs. Standard hand tools like wrenches, socket sets, screwdrivers, and pliers will suffice for the majority of tasks. A multimeter can help diagnose electrical issues, while a compression gauge can check cylinder compression.

Understanding Motor-specific Tools

Some motor-specific tools include a flywheel puller, bearing driver, and gearcase filler. These may not be necessary for basic maintenance, but are crucial for more advanced repairs. Understanding how and when to use these tools can greatly improve your motor repair proficiency.

Creating a Repair Kit

A motor repair kit should contain all of the above tools and a selection of common replacement parts including spark plugs, fuses, and cotter pins. Other useful items include electrical tape, a flashlight, and a small selection of common nuts and bolts. Creating your own repair kit ensures you’re always ready to tackle any issues that crop up, whenever and wherever they occur.

Safety Measures in Outboard Motor Repair

Safety is paramount when dealing with outboard motor repair. Your motor operates under high pressures and temperatures, and can pose risks if mishandled.

Importance of Protective Gear

During repairs, always wear protective gear. This includes safety glasses to guard against flying debris, and gloves to protect your hands from sharp or hot components.

Safety Procedures

Always use the right tool for the job to avoid causing damage or injury. If you’re unsure about a repair, it’s better to consult a professional. Be aware of your surroundings, being careful not to knock over tools or parts that could cause accidents. Keep children and pets away from your workspace.

Handling and Disposal of Chemicals

Working with outboard motors often involves dealing with various chemicals and pollutants like fuel, oil, and lubricants. Handle these with care, using appropriate containers to prevent spills. Also, dispose of these substances responsibly to protect the environment. local regulations will guide you on the correct disposal procedures.

Outboard Motor Maintenance

Proper maintenance is a key factor in the longevity and performance of your outboard motor. Regular, seasonal, and long-term storage maintenance each play integral parts in your motor’s upkeep.

Routine Maintenance

Routine maintenance includes regular checks and replacements of oil, fuel, and spark plugs. Always keep your motor clean and free from debris, and check for any signs of wear and tear.

Seasonal Maintenance

Seasonal maintenance is especially important for those in regions with harsh winters. As the seasons change, so should your maintenance procedures. This includes winterizing your motor with antifreeze, or preparing it for summer with a good clean and polish.

Long-Term Storage Maintenance

If you plan to store your outboard motor for an extended period, prepare it properly to prevent damage. Drain the fuel system to prevent stale fuel problems, change the oil, and ensure it’s thoroughly dry to prevent corrosion.

Outboard Motor Engine Repairs

Dealing with engine issues can be intimidating, but understanding the basics of how your engine works and what each component does will help you approach repairs with confidence.

Repairing the Carburetor

The carburetor plays a pivotal role in the combustion process, mixing air and fuel then feeding it into the cylinders. Problems can arise if it’s dirty or blocked, leading to poor engine performance. Cleaning or replacing a problematic carburetor can often resolve these issues.

Changing the Oil

Changing the engine’s oil is a key part of regular maintenance. It’s a simple task involving draining the old oil, replacing the oil filter, and filling with fresh oil. Always use marine-grade oil and ensure it’s correct for your type of engine – two-stroke or four-stroke.

Dealing with Overheating

Overheating is a common issue in outboard motors and can cause serious damage if left unchecked. Regularly inspect the water pump and the thermostat to ensure they’re working correctly. If your engine is still overheating, professional help may be required.

Replacing a Water Pump

The water pump is essential in keeping your engine cool. If it fails, your engine can quickly overheat and potentially sustain severe damage. Replacement involves removing the lower unit, taking out the old pump, and installing a new one. If you’re not comfortable with this task, seek professional help.

Fuel System Repairs

A well-maintained fuel system is key to your outboard motor’s performance. Understanding how to identify and address common fuel system issues can improve your motor’s efficiency and lifespan.

Identifying Fuel System Problems

Indicator of fuel system issues can range from difficulty starting the engine to poor performance or unusual noises. Check for leaks, clogs in the fuel line or carburetor, or damage to the fuel tank.

Cleaning the Fuel Tank and Lines

Regularly cleaning your fuel tank and lines can prevent common problems. Remove the fuel, clean the interior of the tank with a specific cleaner, and ensure the lines are clear of any blockages.

Replacing Fuel Filters

Fuel filters prevent impurities in the fuel from reaching the engine, so they can clog over time. Regularly inspecting and replacing these filters will ensure your motor gets a clean and steady fuel supply.

Electrical System Repairs

The electrical system plays a critical role in your outboard motor’s operation. Understanding its basic components and how to troubleshoot common issues can keep your motor running smoothly.

Understanding the Electrical System

Your motor’s electrical system includes the battery, alternator, starter motor, and all the wiring and circuits that keep your boat’s electrical components running. It’s responsible for starting your engine, charging your battery, and powering any onboard electronics.

Troubleshooting Electrical Problems

Common problems can include an engine that won’t start, poor performance, or electrical accessories that aren’t working. Always check the battery first, then move on to the alternator, fuses and wiring. A multimeter can be helpful in identifying electrical faults.

Replacing Spark Plugs and Wires

Spark plugs ignite the fuel-air mixture in your engine’s cylinders, while the wires deliver the electricity to the plugs. Regularly checking and replacing these parts can improve your motor’s performance and longevity.

Propeller Repairs and Replacements

The propeller is your boat’s final drive, pushing you through the water. Any issues can seriously hinder your boat’s performance.

Assessing Propeller Damage

Look for signs of damage such as chips, cracks, or bending. Even minor damage can reduce your boat’s performance and fuel efficiency. It’s also crucial to check regularly for any fishing lines or debris wrapped around the propeller shaft, which can cause damage or overheat your engine.

Removing a Damaged Propeller

Removing a damaged propeller involves removing the nut that holds it in place, which usually requires a propeller wrench. Then, slide the propeller off the shaft. Be cautious not to lose any washers or spacers that might be present.

Installing a New Propeller

Installing a new propeller is the reverse of the removal process. Slide the new propeller onto the shaft, replace any washers or spacers in their original positions, and tighten the nut with the propeller wrench. Ensure it spins freely when you’re done.

Outboard Motor Tune-Up

Like any machine, outboard motors benefit greatly from regular tune-ups. It’s a comprehensive check of all the motor components and ensures your motor stays in top shape.

Benefits of Regular Tune-Ups

Tune-ups help prolong your outboard motor’s life and increase its performance. They’re an excellent preventative measure, allowing you to identify and resolve issues before they become major problems. Fuel efficiency can be significantly improved with regular tune-ups, saving you money in the long run.

Step-by-Step Tune-Up Procedure

A typical tune-up includes changing the oil, replacing the spark plugs and fuel filter, cleaning the carburetor, checking the belt and hoses, and inspecting the propeller. Always refer to your owner’s manual for specific recommendations for your motor.

After-Tune-Up Checks

After a tune-up, always check your motor to ensure everything is running smoothly. Listen for any unusual sounds, check for leaks, and ensure the motor starts and runs smoothly. Regular tune-ups and checks like these will ensure you get the most out of your outboard motor and prolong its lifespan.