Maintaining the lifespan of your boat engine isn’t rocket science. It requires some simple steps and regular attention – especially when you’re considering long-term storage. In “How To Properly Store Your Boat Engine For Long-Term Preservation“, you’ll gain useful insights and practical tips to extend the life of your engine and ultimately, enhance your journey on the water. The article has got your back in preventing damage, preserving value, and ensuring when it’s time to hit the waves again, your boat engine roars to life in optimal condition.

Understanding The Importance of Proper Storage

Storing your boat’s engine properly is critical if you want to ensure its longevity and avoid unnecessary expenses on repairs. This article will guide you on how to properly store your boat engine for long-term preservation.

Why proper engine storage matters

In many cases, the engine is the most expensive part of a boat. Like any other machine, it requires regular maintenance, especially if the boat is not in use for some time. Proper storage ensures the moving parts of the engine are protected from wear and tear that can accumulate over time.

Impact of weather on stored engines

The weather can significantly affect the condition of stored engines. Humidity can lead to rust, while extreme temperatures may cause parts to contract or expand, leading to malfunctions when you next start the engine.

Consequences of improper engine storage

Improperly stored engines can bring about a host of problems such as corrosion, brittle seals, and even damage to the engine’s electrical components. Consequently, you may end up spending a lot on unnecessary repairs, or worse, replacements.

Assessing Your Engine’s Current Condition

Before storing your engine, it’s crucial first to assess its current state.

Checking for visible damage

You need to look for any visible signs of damage such as leaks, cracks, or corrosion.

Verifying functionality prior to storage

Another step is verifying the engine’s functionality before storage. Start the engine and observe its operation. If it’s not performing optimally, it may need to be serviced.

Addressing any necessary repairs

Lastly, ensure that any necessary repairs are made before the engine is stored. Storing an engine with existing issues can exacerbate the problem down the line.

Initial Cleaning Process

Once you have assessed your engine’s current condition, the cleaning process begins.

Removing dirt, grime, and salt particles

The first step involves removing any dirt, grime, and salt particles as these can cause corrosion over time if not removed promptly.

Using appropriate cleaning solutions

Not all cleaning solutions are suitable for engines. Therefore, ensure you are using an engine-approved solution.

Importance of a thoroughly clean engine before storage

A thoroughly clean engine ensures that no harmful elements are present that may cause damage over time. Moreover, it’s easier to identify any potential problems in a clean engine than a dirty one.

Draining Fuel and Fluids

Draining fuel and fluids from your engine is another important step in the storage process.

Why draining fuel is necessary

Stagnant fuel can turn stale over time and cause blockages in the fuel system.

The process of fluid and fuel removal

The process involves disconnecting the fuel line from the engine and allowing it to run until it stalls. After that, you’ll need to drain the oil while the engine is warm to effectively remove impurities.

Handling and disposal of old fluids

It’s essential to handle these fluids with care as they can harm you and the environment. Dispose of them responsibly, following the guidelines of your local waste management facility.

Applying Anti-Corrosion Solutions

To further protect your engine, you’ll need to apply anti-corrosion solutions.

Types of anti-corrosion treatments

There are many anti-corrosion treatments such as sprays and specialized oils designed specifically for marine engines.

How to apply anti-corrosion solutions

Typically, these solutions need to be sprayed or brushed on every surface of the engine that’s prone to rusting.

Avoiding common mistakes during application

Some common mistakes to avoid during application include missing hard-to-reach areas. Make sure every part of the engine is adequately covered.

Preventing Moisture Damage

A big part of proper engine storage is preventing moisture damage.

Importance of dry storage

Storing your engine in a dry area helps prevent corrosion and other moisture-related problems.

Solutions for moisture prevention

There are solutions such as dehumidifiers and moisture-absorbing products that can help keep your storage area dry.

Checking for signs of humidity in the storage area

Signs of humidity such as condensation or a damp smell should be addressed promptly to protect your engine from damage.

Protecting Moving Parts

To keep your engine’s moving parts in good shape, you’ll need to protect them as well.

Lubricating joints and mechanisms

Lubricating the engine’s joints and mechanisms keeps them from seizing due to lack of use.

Applying anti-seize treatments

Applying anti-seize treatments on the moving parts can provide extra protection.

Preventing wear-down over time

Regularly checking and lubricating moving parts can prevent wear and tear over time.

Preparing Electrical Components for Storage

It’s also essential to prepare your engine’s electrical components for storage.

Disconnecting batteries

Disconnect the batteries to prevent them from draining and causing damage to the electrical system.

Insulating wires and terminals

Use insulating tape to protect your engine’s wires and terminals from exposure to moisture.

Avoidance of electrical shorts in storage

Making sure all your engine’s electrical components are properly insulated can prevent electrical shorts during storage.

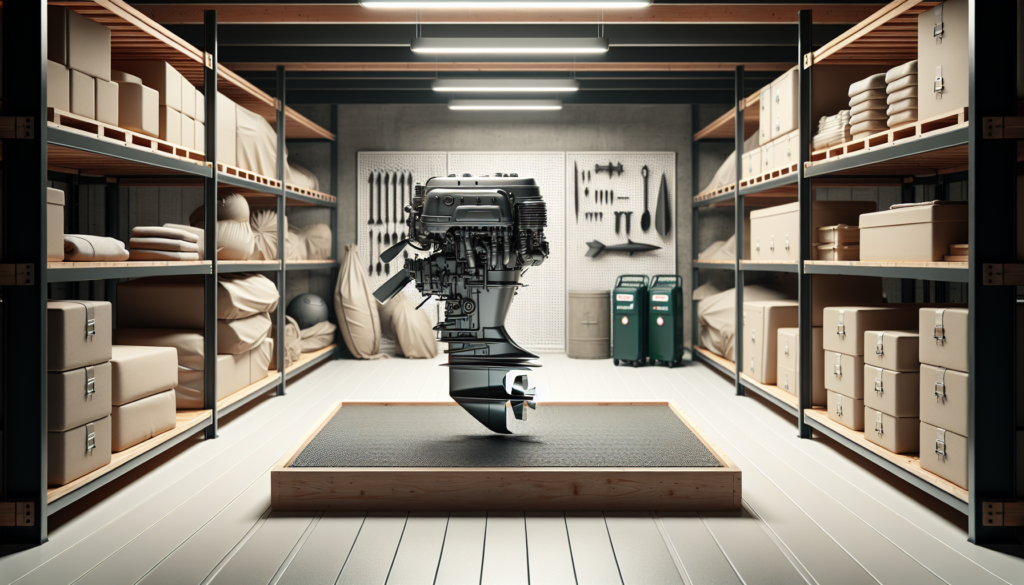

Choosing A Suitable Storage Area

The place where you store your engine is crucial in determining how well it will be preserved.

Ideal conditions for engine storage

The perfect storage area should be cool, dry, and free of dust.

Indoor vs. outdoor storage considerations

While indoor storage is preferable, if outdoor storage is your only option, ensure that your engine is fully enclosed and protected from the elements.

Space requirements for storing boat engines

Ensure the space is large enough for your engine, allowing room for maintenance and any additional storage requirements.

Regular Checks and Maintenance During Storage

Remember, storing your engine doesn’t mean forgetting about it.

Frequency of check-ins on stored engine

It’s recommended to check on your stored engine at least once a month.

Common problems in long-term storage

Address rust, battery drain, and fluid leaks as they are common problems in long-term storage.

Re-starting the engine after storage

Before you start the engine, conduct a thorough inspection, and ensure the battery is fully charged.

Properly storing your boat engine can save you a lot of headache down the line. A well-preserved engine ensures great water adventures for years to come.

[…] is fast approaching and, as a boat owner, it is time to start thinking about how to prepare your engine for the chilly months ahead. The article “The Best Ways To Winterize Your Boat Engine For Cold Weather Storage” […]