Picture yourself in the middle of a lake, basking in the cool breeze on your boat when suddenly your boat engine starts showing signs of power loss. It’s a scenario that sends shivers down any boat owner’s spine. But don’t worry, this comprehensive guide on how to troubleshoot boat engine power loss arms you with insights and practical steps to detect and fix these issues swiftly. You’ll find simple yet effective strategies and procedures to recognize the key signs of power loss and respond appropriately to solve the problem on your own. Your boat engine power loss woes will soon be a thing of the past!

Understanding the Basics of Boat Engines

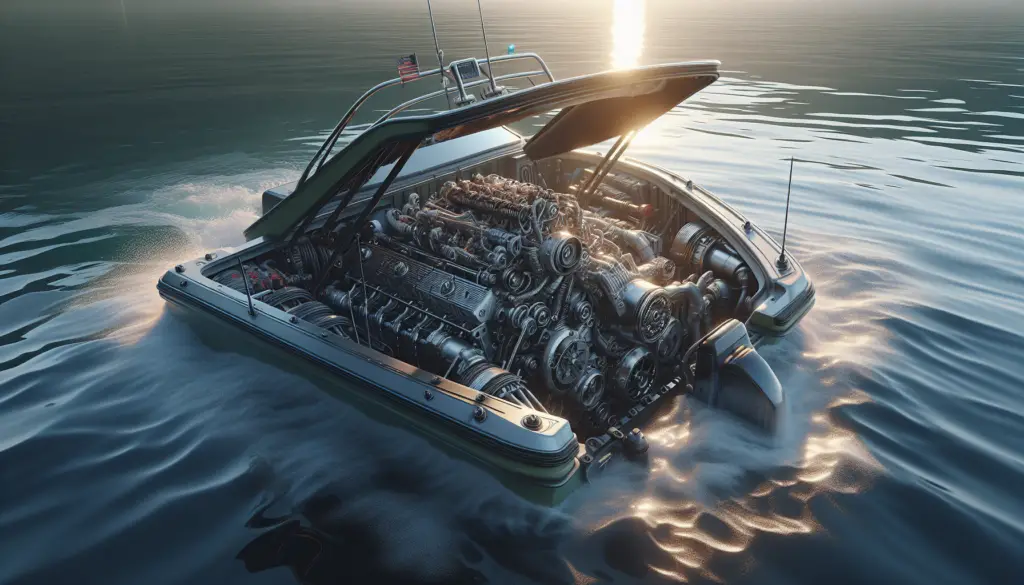

An engine is the heart of your boat, it’s what propels you across the surface of the water. But to keep it cranking, you need to understand the basics.

Types of Boat Engines

If you’re new to boating, you might not realize that there are several different types of boat engines. These include outboard motors, which are designed to be mounted on the boat’s stern, and inboard motors, which are used in larger boats and are installed inside the hull. Jet engines and stern drives, on the other hand, provide alternatives to traditional propeller-driven boats. Which type you’ll need depends on the size and intended use of your boat.

Key Components of Boat Engines

Each type of boat engine has essential components that enable it to operate properly. The key parts of a boat engine include the propeller, the drive shaft, the engine block, the spark plugs, and the fuel injector, just to name a few. Each of these parts plays a crucial role in the functioning and operation of the engine.

Common Points of Failure in Boat Engines

Despite being built for resilience, boat engines are susceptible to various points of failure. These range from overheating due to a faulty cooling system, fuel system issues such as blockages in the fuel lines or trouble with the fuel pump, electrical problems, and propeller or drive shaft damage.

Symptoms of Boat Engine Power Loss

Any boat enthusiast will tell you that engine power loss is a common problem that can ruin a leisurely day on the water. Recognizing these symptoms can help you get back to shore without trouble.

Difficulty Starting the Engine

Just like your car, if your boat engine is having trouble starting, this can be a clear sign of engine power loss. This might be due to various problems like a weak battery, worn-out spark plugs, or a failing ignition system.

Lack of Speed

If you notice a sudden or gradual decrease in your boat’s speed, this could indicate a problem with engine power. This might stem from a failing propulsion system, clogged fuel lines, or even an improperly pitched or damaged propeller.

Engine Stalling

Frequent stalling often points to a problem with the fuel or ignition system. It could be due to issues such as blockages in the fuel system, faulty spark plugs, or even issues with the boat engine’s carburetor.

Overheating

An overheating engine is a serious issue that could result in complete engine failure if ignored. This could stem from a failing cooling system, a damaged water pump, or blocked coolant passages.

Increased Fuel Consumption

A sudden increase in fuel consumption can indicate a power loss in boat engines. This may be due to improper tuning of the engine, an overly rich fuel mixture, or a failing ignition system.

Inspecting the Fuel System

The fuel system plays a vital role in ensuring your engine runs smoothly. Inspecting it can help identify any potential issues.

Checking for Blockages in the Fuel Lines

Blocked fuel lines can restrict the supply of fuel to your engine, causing power loss. Regular inspection can help identify any clogs or leaks that might be reducing fuel flow.

Inspecting the Fuel Tank for Contamination

Contaminants in the fuel tank, like water or debris, can cause severe engine issues. Therefore, regular checks for contamination are essential for maintaining a healthy engine.

Checking the Fuel Pump and Filter

A dysfunctional fuel pump or a clogged filter can significantly degrade your engine’s performance. Make it a habit to inspect these parts regularly to ensure they’re functioning correctly.

Potential Issues with the Carburetor

The carburetor plays an essential role in mixing the right amount of air with fuel. Any issues with it can disrupt this balance, causing power loss.

Testing the Fuel Pressure

Verifying the fuel pressure can help detect issues before they worsen. It ensures enough fuel is reaching the engine to keep it running smoothly.

Testing the Engine Compression

Performing an engine compression test can help elucidate the overall health of your boat engine.

Understanding the Role of Compression in the Engine

Compression is the process of pressing the air-fuel mixture in the engine cylinder, preparing it for ignition. This process is vital for your boat engine’s correct functioning.

Signs of Poor Compression

Some signs of poor engine compression include the engine turning over but not starting, loss of engine power, and increased exhaust emissions. These symptoms may indicate a leak in the engines’ cylinder.

How to Conduct a Compression Test

To conduct a compression test, you’ll need to disable the fuel and ignition systems, remove a spark plug, connect the compression tester, and then crank the engine to measure the pressure build-up in the cylinder.

Interpreting the Results of a Compression Test

A good boat engine should have a compression reading between 90 and 110 psi. If the reading is significantly low, or there’s a large discrepancy between cylinders, it indicates an engine problem.

Assessing the Ignition System

Testing the ignition system is a crucial aspect of any boat engine diagnostic.

How the Ignition System Works

The ignition system is responsible for igniting the air-fuel mixture in the engine cylinders, which powers the engine.

Testing the Spark Plugs

Faulty spark plugs can cause power loss in your engine. Testing them can help identify any misfires that could be disrupting the combustion process.

Inspecting the Ignition Coil

A faulty ignition coil can cause a weak spark or no spark at all, leading to engine power loss. Regular inspection can ensure it’s functioning correctly.

Potential Problems with the Rotor and Distributor Cap

The rotor and distributor cap are responsible for channeling the spark to the right cylinder at the right time. Any problems with these components can disrupt the ignition process.

Checking the Timing of the Ignition System

Incorrect ignition timing can result in inefficient burning of the air-fuel mixture, leading to power loss. Therefore, it is important to regularly check the ignition timing.

Examining the Propulsion System

An efficient propulsion system is key to achieving optimal performance with your boat engine.

Overview of the Propulsion System

The propulsion system includes the mechanism that converts the rotational power from the engine shaft into linear motion to propel the boat.

Analysis of the Propeller

The propeller plays a key role in pushing your boat through the water. A damaged, worn-out or improperly sized propeller can reduce your speed and overall performance.

Issues with the Gear Case

The gear case, or gearbox, is responsible for transmitting the power from the engine to the propeller. Any damage, misalignment, or problems with the gears can lead to power loss.

Diagnosing problems with the Drive Shaft

The drive shaft transfers the power from the engine to the propeller. Damaged or bent drive shafts can cause significant performance issues.

Evaluating the Cooling System

The cooling system is crucial in preventing your boat engine from overheating.

Role of the Cooling System

The cooling system’s job is to regulate the engine’s temperature by circulating coolant through engine components, absorbing heat, and dissipating it away from the engine.

Signs of Cooling System Failure

Signs of cooling system failure include overheating, coolant leaks, and poor engine performance. If ignored, a failing cooling system could lead to significant engine damage.

Checking the Radiator and Water Pump

The radiator and water pump play a key role in cooling down the engine. A faulty pump or an obstructed radiator can restrict the flow of coolant, leading to overheating.

Examining the Thermostat

The thermostat controls the flow of coolant based on the engine’s temperature. A malfunctioning thermostat might block the coolant’s flow or allow too much flow even when the engine is cold.

Testing the Coolant Fluid Level and Quality

The coolant’s quality and level significantly affect engine cooling. Regularly checking these two aspects can prevent potential overheating issues.

Performing Engine Diagnostics

Performing engine diagnostics can help you identify potential issues before they turn into severe problems.

How Engine Diagnostics Can Help Identify Power Loss

Diagnostics can help you pinpoint what’s causing your engine’s power loss. This information can help you address the issue promptly and avoid further damage.

Types of Diagnostic Tools and Software

Diagnostic tools and software come in various forms, ranging from handheld devices to computer software, which provide real-time data about your engine’s performance.

Interpreting Diagnostic Codes

Diagnostic codes are generated by your boat’s computer system when it detects an issue. Understanding these codes can help you identify and fix the specific problem.

Routine Engine Monitoring for Early Detection

Regularly monitoring your engine can give you early warnings of potential issues, allowing you to address them before they cause significant damage.

Fixing Identified Problems

Identifying the problem is half the battle, fixing it is the other half.

Repair vs. Replacement Considerations

Not all broken parts need to be replaced – sometimes, a simple repair may do the trick. However, in some cases, replacing the part may be the more economical and reliable choice.

Finding Quality Parts

When performing repairs, it’s crucial to use quality parts. This can ensure your boat engine performs at its best for as long as possible.

Safety Measures When Performing Repairs

Always prioritize your safety when performing repairs. Wear appropriate safety gear, disconnect the power supply, and follow the manufacturer’s guidelines.

Knowing When to Consult a Professional

Some repairs are best left to professionals. If you’re unsure about a repair or are uncomfortable performing it, don’t hesitate to seek professional help.

Preventive Measures and Regular Maintenance

Prevention is better than cure. Regular preventive maintenance helps maintain the longevity and performance of your boat engine.

Importance of Regular Maintenance

regular maintenance can help identify potential issues before they become serious problems, extend the life of your engine, and keep it running smoothly and efficiently.

Recommended Maintenance Schedules

Adhering to the manufacturer’s maintenance schedules can prevent potential power loss incidents. These typically include regular inspections, part replacements, and adjustments.

Preventive Measures to Avoid Power Loss

Simple preventive measures like regular engine cleaning, using quality fuel, and routine inspections can go a long way in preventing engine power loss.

Keeping an Engine Logbook for Tracking

An engine logbook can be instrumental in tracking your boat’s performance over time, noting repairs and replacements, and scheduling preventive maintenance. This will help ensure your engine runs at optimal performance and lasts longer.