Feeling the gentle sway of your boat on the water is one thing, but feeling an unusual vibration is quite another. It can be both confusing and disturbing, especially if you’re not sure what’s causing the unsettling sensation. Fortunately, you don’t need to be a master mechanic to figure out what’s going wrong. In “Boat Engine Troubleshooting for Vibration Issues,” we’ve compiled a list of common culprits behind unwelcome tremors and a guide on how to resolve them. This is your handy path to smoother, more enjoyable boating adventures.

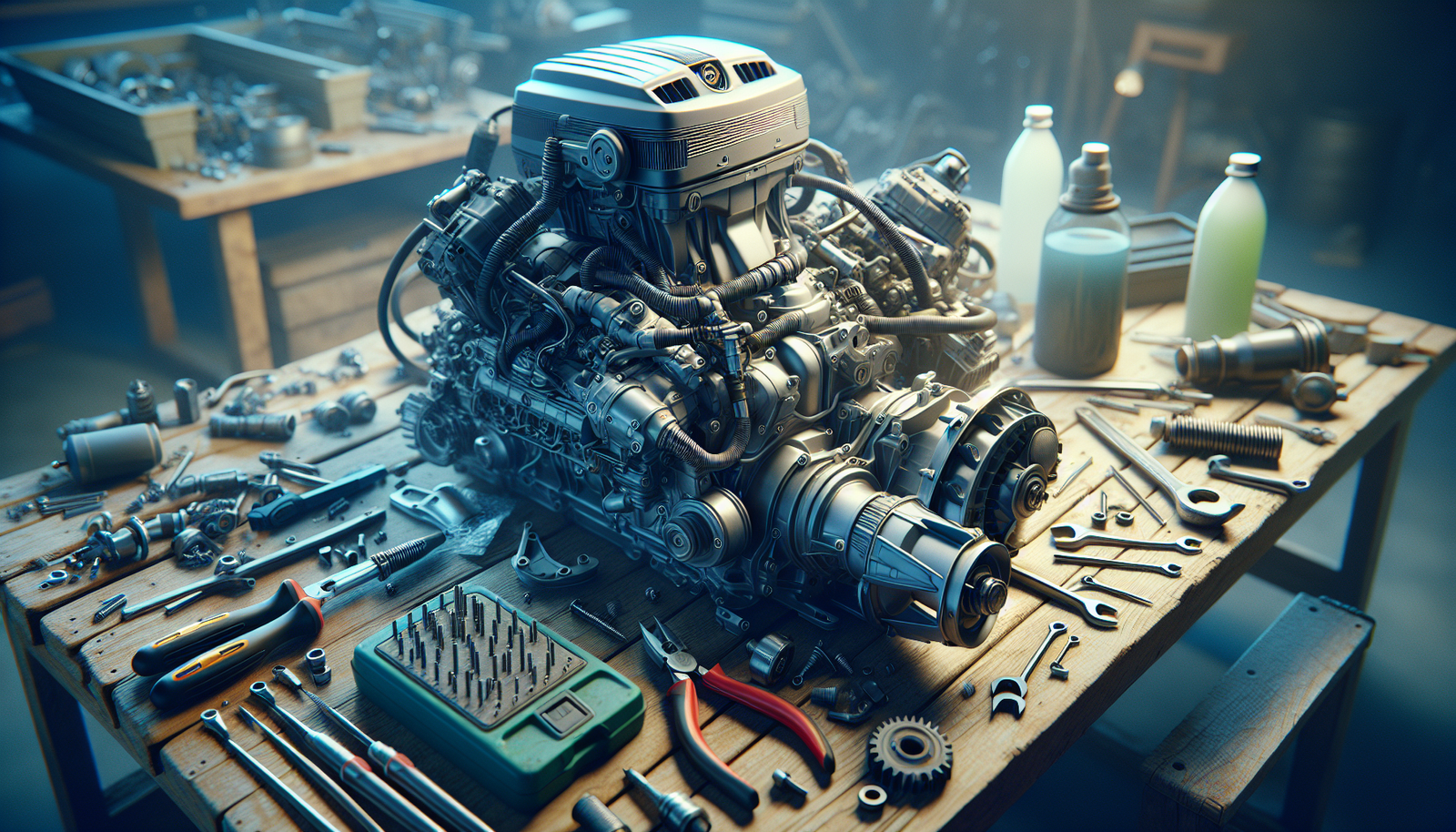

Understanding the Cause of Vibration

As a boat owner, it’s crucial to grasp what causes vibration in your vessel’s engine. Engine vibration is a common issue that can have a variety of sources and forms which can affect the performance of your boat and its parts.

Identifying common causes of boat engine vibration

There are several possible culprits behind boat engine vibrations. This could be an issue with the propeller, engine mounts, drive shaft, exhaust system, transmission, or cooling system. Each of these components plays a crucial role in the overall functioning of your boat’s engine and any malfunction can result in vibration of the entire system.

Exploring different types of vibrations

Vibrations can manifest in various ways; there can be low-intensity vibrations that are barely noticeable, while at other times, vibrations can be felt throughout the entire boat. Vibrations can be continuous or sporadic, and their intensity can vary. Paying attention to these details can help in identifying the source of the problem.

How engine misalignment causes vibration

Engine misalignment is one of the most common causes of boat engine vibration. When engine parts are not properly aligned, it can cause the engine to shake or vibrate. The vibration becomes more noticeable as the engine’s RPMs increase and can lead to significant damage if left unattended.

Effects of Vibration on Boat Engine

Vibration in boat engines is not just an annoyance; it can have significant ramifications that impact both the vessel’s performance and integrity.

Negative impacts of continuous vibration

Continuous vibration can have serious damaging effects on your boat’s engine. It can cause wear and tear on moving parts, leading to mechanical failure. Additionally, it can result in decreased fuel economy, as the engine has to work harder due to the vibrations.

Structural damage due to extreme vibration

In cases of severe vibration, even the boat’s structure can be at risk. Extreme vibrations can lead to structural cracks, especially in older boats. These vibrations can damage the hull, leading to expensive repairs and potentially hazardous situations.

Influence of vibration on engine performance

Engine vibration can significantly impact the engine’s performance. It can decrease the engine’s power output, its efficiency and can lead to complete engine failure if left unchecked. This not only reduces the engine’s lifespan but also compromises its reliability.

Diagnosing the Vibration Problem

Identifying vibration issues in your boat’s engine requires a strategic approach. Understanding the best tools and diagnostics can save you time and money.

Steps to diagnose vibration in boat engines

To diagnose the vibration problem, start by observing when and where the vibration occurs. Identify whether the vibrations coincide with engine acceleration or if they’re consistent. Next, inspect different components such as the propeller, drive shaft, and engine mounts to identify any visible issues.

Useful tools for diagnosing vibration

Diagnosing engine vibrations will often require specialized tools. These can include a stethoscope to isolate the source of the noise, an alignment tool to check for misalignment in the engine, and a propeller balancer to verify the balance of the propeller.

Conducting a diesel engine diagnostic

Diagnosing a diesel engine is similar to other engine types. Begin by listening for unusual noises since these can often point to the presence of issues causing vibrations. Then, conduct a thorough examination of all the components that could potentially cause vibration.

Inspecting the Propeller

The propeller is a critical part of the vessel and could be behind the vibrations you’re experiencing.

Issues with the propeller that cause vibration

Various propeller problems can result in engine vibrations. These may include a bent or damaged propeller, an unbalanced propeller, and even small deposits or marine growth on the propeller can cause vibrations.

Checking the propeller for bends or cracks

Once you’ve identified the propeller as a potential issue, inspect it thoroughly for any visible damage. Look for dents, bends, or cracks, which can offset the propeller’s balance and cause vibrations.

The role of propeller balance in reducing vibration

Propeller balance is essential for smooth operation. An unbalanced propeller can lead to vibration, inefficiency, and strain on the engine’s bearings. Ensuring your propeller is balanced, free of imperfections or deposits is crucial in maintaining smooth operation and reducing vibration.

Examining the Engine Mounts

Engine mounts play a significant role in stabilizing the engine, and if these mounts are worn or damaged, they could be causing vibrations.

The role of engine mounts in stabilizing engine

Engine mounts are designed to hold the engine in place securely while dampening any vibrations produced by the engine’s operation. If these mounts are functioning correctly, it reduces the vibrations that transfer from the engine to the boat’s structure.

Detecting signs of worn-out engine mounts

Warning signs that engine mounts may need replacement include a visible sagging of the engine, increased noise and vibration, and even movement of the engine while it’s running. Worn-out engine mounts fail to isolate the engine’s vibrations, leading to noticeable shaking in your boat.

Replacing or repairing damaged engine mounts

If the engine mounts are damaged or worn, they will need to be replaced or repaired. This process involves lifting the engine, removing the old mounts, and installing new ones. Remember, it is essential to keep these mounts in good working condition to maintain a smooth and stable engine operation.

Checking the Drive Shaft

The drive shaft is another critical component that can create vibrations if it’s not operating correctly.

Imbalance in the drive shaft leading to vibration

The drive shaft must remain balanced for the engine to operate smoothly. Any imbalance in the drive shaft can cause significant vibrations when the boat is in motion. This could be due to wear and tear over time or some type of damage.

Regular maintenance of the drive shaft

Maintaining the drive shaft requires regular inspection to ensure there’s no visible damage or wear. This might involve checking for any bends, pitting, or rust formation. It’s also recommended to regularly lubricate the drive shaft to prevent wear and tear.

Replacement of a faulty drive shaft

If the drive shaft is damaged or excessively worn, it should be replaced to avoid further engine damage. Remember, a smooth, balanced drive shaft is crucial for a vibration-free operation.

Investigating the Exhaust System

A failing exhaust system can also contribute to engine vibration and decrease performance.

Understanding the exhaust system’s role in engine vibration

The exhaust system ensures that gases from the engine are safely expelled. If this system fails or is damaged, it can lead to increased engine vibrations due to the irregular flow of exhaust gases.

Symptoms of a failing exhaust system

Signs of a failing exhaust system include louder than normal engine noise, reduced performance, and the smell of exhaust inside the boat. A visible inspection may reveal leaks or holes in exhaust pipes or components.

Repairing or replacing parts of the exhaust system

Damaged or failing exhaust components can be repaired or replaced as necessary. Always ensure that the system is inspected regularly and kept in good condition to prevent issues related to engine vibration.

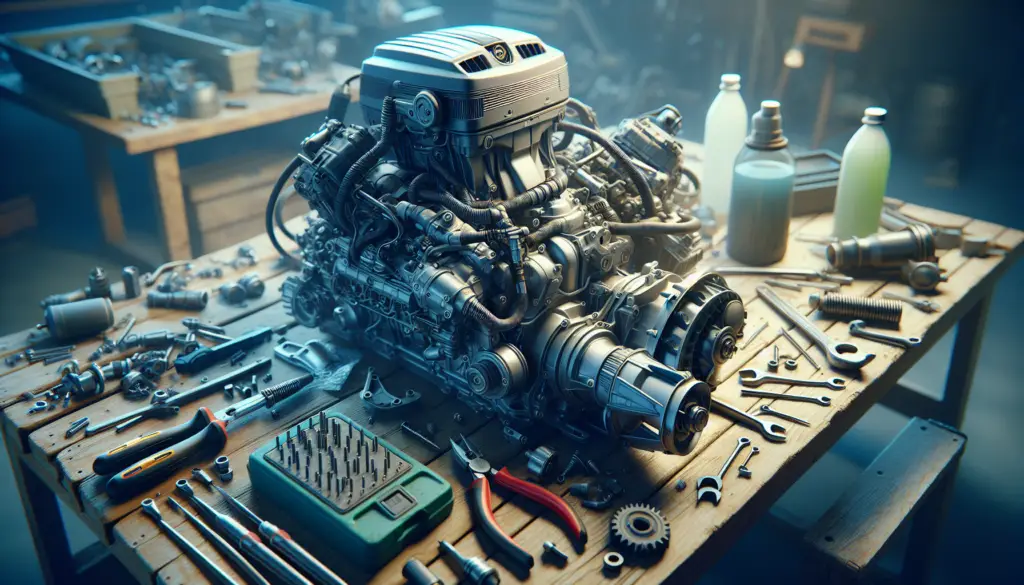

Reviewing the Transmission

Transmission issues can create vibrations and drastically affect your boat’s performance.

Identifying transmission problems leading to vibration

Your transmission can be a source of vibration if it’s not handling the transfer of power from the engine to the drive shaft correctly. Issues like gear misalignment, worn-out components, or even low transmission fluid can contribute to system vibrations.

Maintenance tips for the transmission system

Ensuring that your transmission system is well maintained can prevent vibration issues. This includes regularly checking the transmission fluid levels, inspecting and replacing worn-out parts, and ensuring gears are properly aligned.

Replacing a faulty transmission

In cases where the transmission is faulty or severely damaged, it may need to be replaced. A faulty transmission not only causes vibration but can also affect your boat’s overall performance.

Exploring the Cooling System

The cooling system plays a crucial role in engine operation and its malfunction can result in vibrations.

The cooling system and its part in engine vibration

The cooling system ensures that the engine does not overheat, allowing it to run smoothly and efficiently. However, factors such as leaking coolant, a failed water pump, or blocked coolant passages can lead to engine vibrations.

Signs of cooling system problems

Signs of a problem with your cooling system can include the engine overheating, coolant leakage, or the cabin area becoming unusually warm. An inspection might reveal issues such as a broken water pump or blocked coolant passages.

Maintenance and replacement of cooling system parts

Regular maintenance of the cooling system is crucial in preventing engine vibrations. This includes checking coolant levels regularly, ensuring the water pump is functioning correctly, and keeping the coolant passages clear.

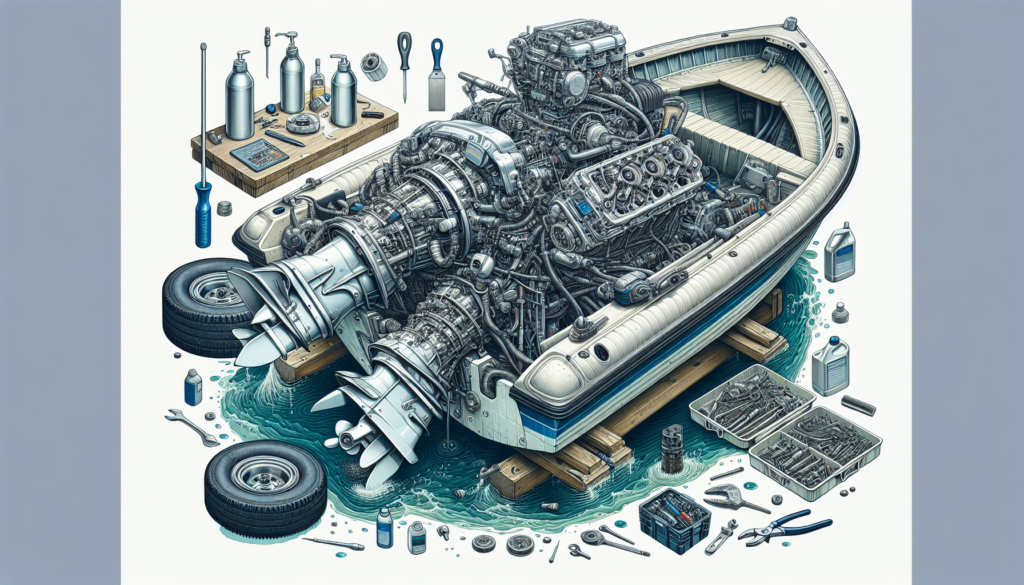

Maintenance Schedule to Prevent Vibration

To keep boat engine vibrations at bay, regular maintenance and timely inspections are essential.

The importance of regular engine maintenance

Regular engine maintenance goes a long way in preventing vibration. It ensures every component is working as it should, thereby reducing the potential for unexpected wear or failure which could result in vibration.

Creating a maintenance schedule

Creating a maintenance schedule can help ensure that you check each component of your boat’s engine regularly for potential issues. The schedule should include regular checks of engine alignment, propeller condition, engine mounts, the drive shaft, the exhaust system, the transmission, and the cooling system.

Key aspects of a thorough engine check-up

A thorough check-up of your boat’s engine should include several key aspects. This includes checking the functioning and alignment of all movable parts, inspecting for any visible damage, and keeping the boat engine clean and well-lubricated. Regular check-ups can help identify potential issues before they become significant problems and lead to engine vibration.

Monitoring your boat’s engine closely, conducting regular check-ups, and dealing with issues promptly can help prevent engine vibrations and ensure smooth sailing at all times. Using this approach, you can keep your boat in top shape and enhance your overall boating experience.