If you’re looking to enhance the sound and vibration control of your engine, then engine customization may be the solution you’ve been searching for. By customizing your engine, you have the opportunity to fine-tune various components to optimize performance and minimize unwanted noise and vibrations. In this article, we will explore some effective techniques and modifications that can help you achieve a smoother and quieter engine experience, allowing you to enjoy a more peaceful and enjoyable ride. So, let’s get started on this journey towards enhanced sound and vibration control with engine customization.

Choosing the Right Engine

When it comes to enhancing sound and vibration control with engine customization, the first step is choosing the right engine for your specific needs. Understanding engine types is essential in making an informed decision. There are various engine types available, including inline engines, V engines, flat engines, and rotary engines.

Inline engines are a popular choice for their simplicity and compact design. They have all cylinders arranged in a single line, making them suitable for smaller vehicles. V engines, on the other hand, have cylinders arranged in a V shape, offering better performance and power. Flat engines, also known as horizontally opposed engines, have cylinders placed horizontally, providing a lower center of gravity and improved balance. Lastly, rotary engines have a unique design that allows for high power output and smooth operation.

Considering your performance needs is another crucial aspect of choosing the right engine. If you’re looking for a high-performance engine with increased power, a V engine or a rotary engine might be the ideal choice. However, if fuel efficiency and compact size are your priorities, an inline engine or a flat engine would be more suitable.

Furthermore, evaluating noise levels is essential when selecting an engine. Different engine types produce varying levels of noise, and it’s important to consider your noise tolerance. If you prefer a quieter engine, an inline engine or a V engine with proper sound control measures might be more appropriate.

Lastly, assessing vibration levels is vital for a comfortable driving experience. Some engines have inherent vibration characteristics, while others can be smoother with the right engine mounts and vibration dampeners. Consider your vibration tolerance and the type of vehicle you have when selecting an engine.

By taking these factors into account, you can choose an engine that aligns with your needs and sets a solid foundation for enhancing sound and vibration control through customization.

Selecting Engine Components

Once you have chosen the right engine, it’s time to focus on selecting the appropriate engine components to enhance sound and vibration control further. There are several components to consider, including mufflers and exhaust systems, sound deadening materials, engine mounts, and vibration dampeners.

Mufflers and exhaust systems play a significant role in reducing engine noise. Upgrading your muffler to a high-quality aftermarket one can significantly decrease noise levels. Additionally, replacing the entire exhaust system with a performance-oriented one can further enhance sound control. It’s important to ensure that the new system is compatible with your vehicle and meets local regulations.

Sound deadening materials are another crucial aspect of sound control in an engine. There are different types of sound deadening materials available, such as mass-loaded vinyl, foam, and vibration-damping mats. These materials can be applied to various areas of the engine compartment to reduce noise transmission. They are particularly effective when installed in areas where vibrations are transferred, such as the firewall and the interior of the vehicle.

Engine mounts are responsible for absorbing engine vibration and reducing its transmission to the vehicle’s chassis. Upgrading to high-quality engine mounts can significantly improve vibration control. Understanding different mount types, such as hydraulic, rubber, and polyurethane, is important when selecting the right mounts for your engine. Each mount type offers different levels of vibration isolation, so it’s crucial to consider your specific needs.

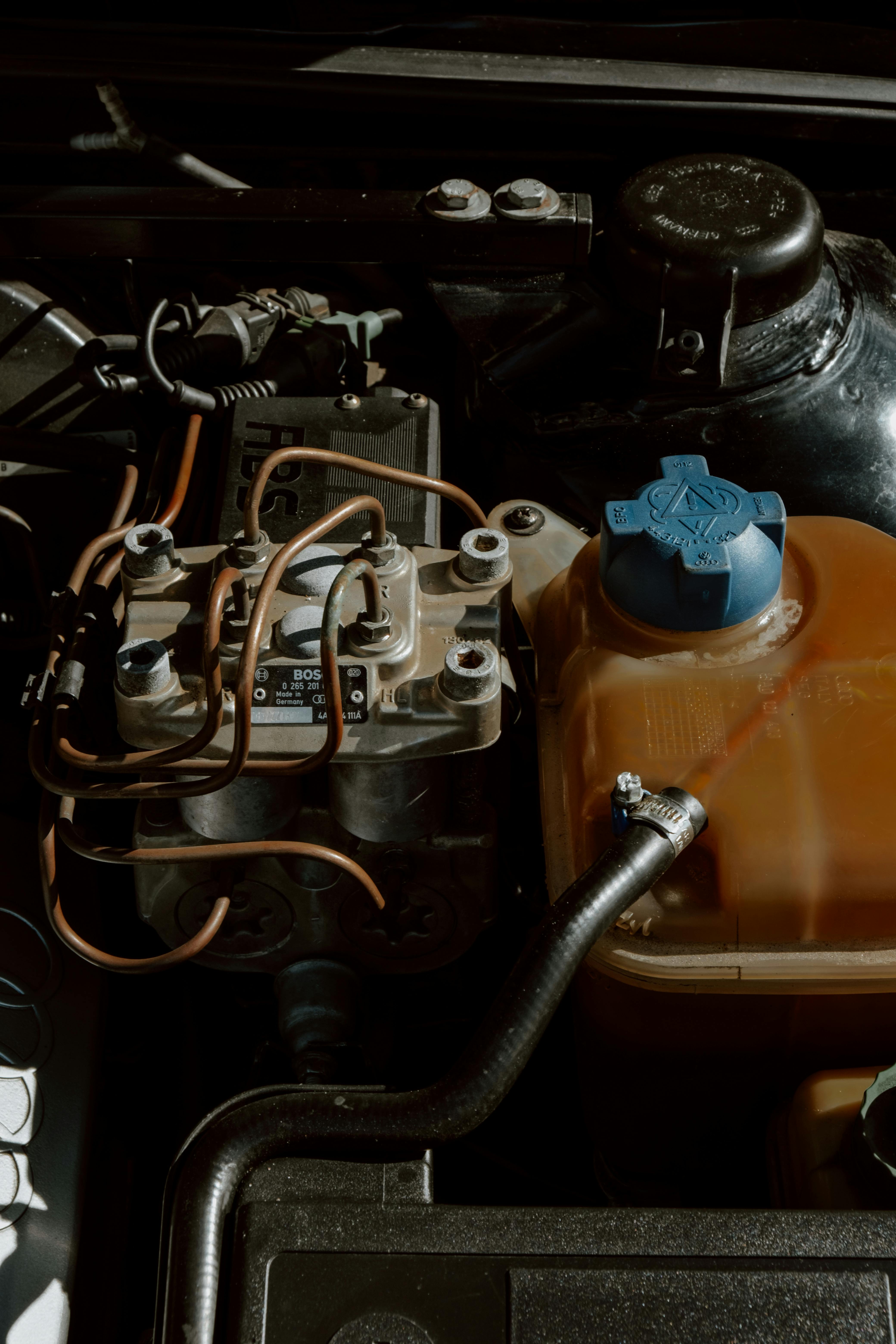

Vibration dampeners, also known as harmonic balancers, help reduce and control engine vibrations. They work by counteracting the engine’s natural vibrations and preventing them from causing excessive movement. Vibration dampeners are typically installed at the front of the engine, and choosing the right one for your engine is essential for optimal vibration control.

By carefully selecting these engine components, you can effectively enhance sound and vibration control, leading to a quieter and smoother driving experience.

Optimizing Exhaust System

An essential aspect of sound and vibration control in an engine is optimizing the exhaust system. Upgrading mufflers, using resonators, and considering catalytic converters are key steps in achieving this optimization.

Upgrading your mufflers is one of the most straightforward ways to improve sound control. High-quality aftermarket mufflers are designed to reduce noise while maintaining performance. They incorporate advanced technology, such as sound chambers and baffles, to suppress unwanted noise frequencies. When choosing a new muffler, consider factors such as noise reduction capabilities, ease of installation, and compatibility with your vehicle.

Resonators are another component that can be added to the exhaust system to enhance sound control. They are designed to reduce specific frequencies of noise, achieving a more pleasant exhaust note. Resonators work by creating sound waves that cancel out the undesirable frequencies. Adding resonators can provide a noticeable improvement in sound quality and control.

Catalytic converters, though primarily responsible for reducing emissions, can also contribute to sound control. High-flow catalytic converters are designed to reduce backpressure in the exhaust system, allowing for better airflow and improved engine performance. They can also help reduce exhaust noise to some extent. It’s important to ensure that any modifications to the catalytic converter comply with local emissions regulations.

For turbocharged engines, special consideration should be given to optimizing the exhaust system. Turbocharged engines produce additional noise due to the turbocharger’s operation. Upgrading the exhaust system with larger-diameter piping, performance-oriented mufflers, and resonators specifically designed for turbo applications can help achieve a better balance between performance and sound control.

By optimizing the exhaust system, you can effectively enhance sound control while maintaining the desired performance of your engine.

Using Sound Deadening Materials

Sound deadening materials are a valuable tool in achieving superior sound control in an engine. Understanding the different types of materials, proper installation techniques, and target areas for sound deadening is essential.

There are various types of sound deadening materials available, each with its specific characteristics and applications. Mass-loaded vinyl (MLV) is a dense and flexible material that acts as a barrier to block sound transmission. It is effective in reducing airborne noise, such as engine noise, when applied to the firewall and other exposed areas. Foam materials, such as closed-cell foam or open-cell foam, can be used to absorb sound waves and reduce resonance. Vibration-damping mats, often made from butyl rubber or asphalt, are designed to reduce vibrations and lower noise levels.

Proper installation techniques are crucial for maximizing the effectiveness of sound deadening materials. Ensure that the materials are applied to clean and properly-prepped surfaces for optimal adhesion. Use techniques such as overlapping seams, using roller tools to apply pressure, and trimming excess material to achieve a neat and professional finish.

When applying sound deadening materials, target the areas where sound transmission and vibration transfer are most prominent. These areas typically include the firewall, floor pan, doors, and trunk. Additionally, consider covering large panels and cavities to minimize vibration and rattling noises.

By utilizing sound deadening materials effectively, you can significantly reduce engine noise and create a more peaceful driving environment.

[…] consider the build quality of the parts. Are they designed and manufactured to withstand the vibrations, shocks, and stresses that boat engines often face? It’s important to choose parts that are built to last, as this will save you from frequent […]