Owning a boat can be an exhilarating experience, offering you limitless aquatic adventures. However, it comes with its own set of maintenance requirements, especially when it comes to the engine’s cooling system. In this article, “How To Properly Service Your Boat Engine’s Cooling System,” you will be guided through the process of ensuring your boat’s engine cooling system is operating at peak efficiency. The article is a treasure trove of practical tips and step-by-step instructions, ensuring your boat will dish out optimum performance while safeguarding against any untimely maritime mishaps due to a neglectful cooling system. So, get ready to become proficient in keeping your boat engine’s cooling system in top shape.

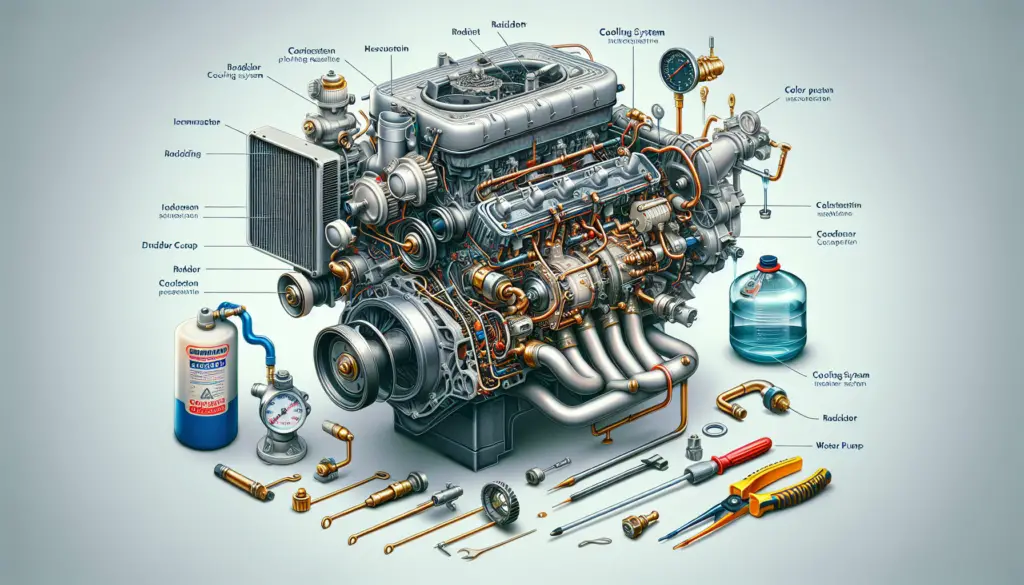

Understanding the Cooling System

Possessing the right knowledge about your boat engine’s cooling system is critical for your boat’s overall performance and your peace of mind while you’re out on the water.

Basics of a Boat Engine Cooling System

Think of your boat’s cooling system as its guardian agent against overheating. The cooling system regulates the boat engine’s temperature, removing excess heat produced during combustion, and keeping the engine functioning efficiently at safe temperature levels.

Types of Cooling Systems: Raw Water Cooling and Closed Cooling

Your boat operates either on a raw water cooling system or a closed cooling system. Raw water cooling system, the simpler one, cools the engine by pumping water into the engine from the body of water you’re cruising. On the other hand, a closed cooling system operates like a car’s radiator. A coolant, often a mix of antifreeze and water, circulates around the engine block, collecting heat as it goes before being cooled down by a raw-water heat exchanger.

Importance of Regular Servicing

Like any mechanical system, your boat’s cooling system requires regular servicing. Regular maintenance ensures optimal performance, proactive identification of component wear and tear, and ultimately, a longer lifespan for your boat engine.

Signs Your Cooling System Needs Service

Knowing when your cooling system needs service can save you from engine breakdowns.

Temperature irregularities

Watch for temperature irregularities. If your engine is running hotter than usual, your cooling system may be the culprit. Temperature spikes could indicate blockages in the cooling system or a faulty water pump.

Visible leaks or corrosion

Look for visible signs, like coolant leakages or signs of corrosion on the engine block. Such signs suggest a potential breach in the system’s integrity, demand urgent attention.

Drop in engine performance

Finally, a general drop in engine performance can also point to problems within the cooling system. Pay attention to changes in engine noise, fuel efficiency, or unexplained losses in speed or power.

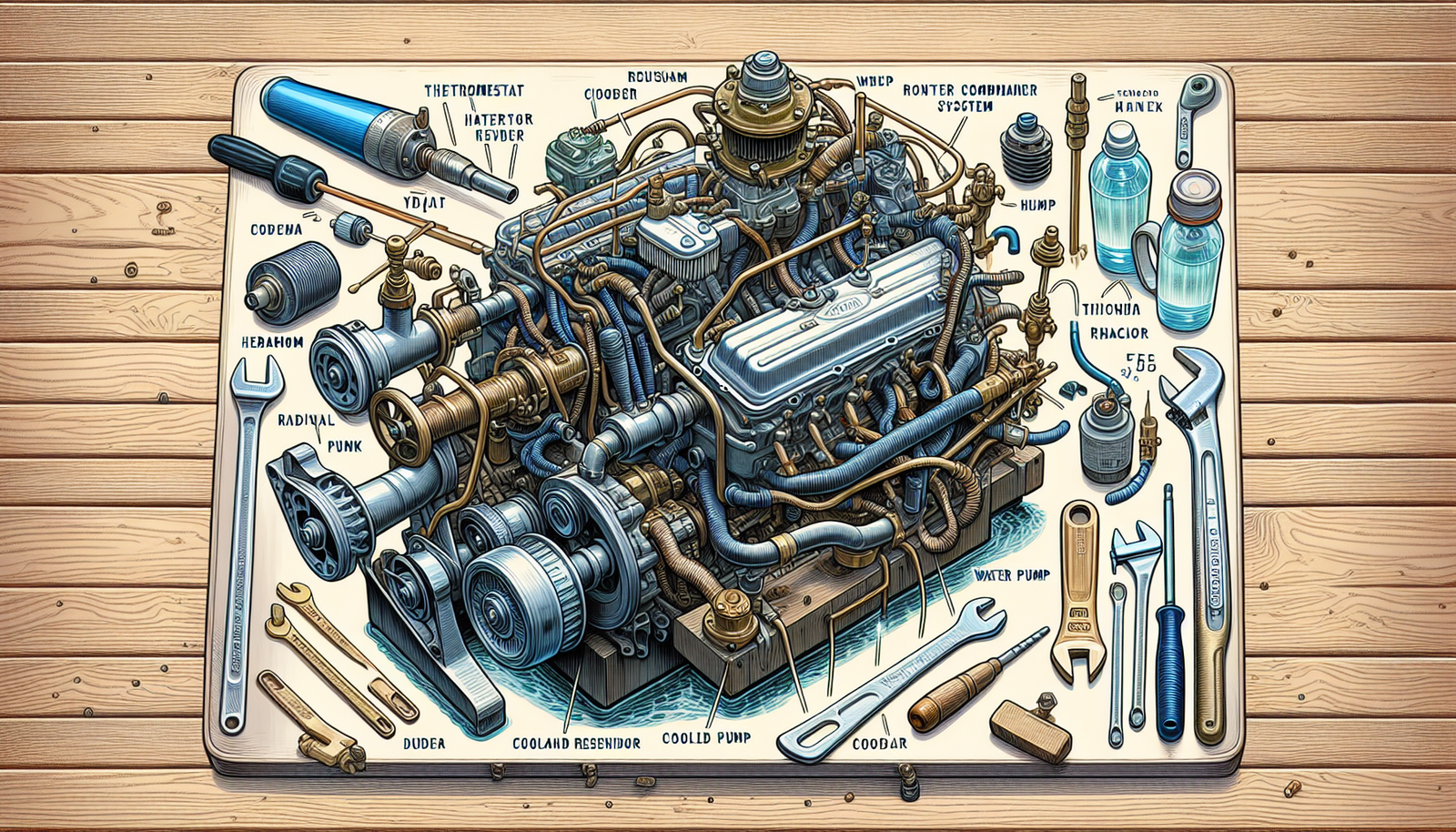

Tools You Will Need for Servicing

Having the right tools on hand will make servicing your boat’s cooling system a breeze.

Common Household Tools

Common household tools you’ll often need include wrenches, pliers, and screwdrivers. Additionally, buckets or pans for draining coolant and old rags for clean-up will be useful.

Specialized Boat Repair Tools

Specialized boat repair tools will go a long way in simplifying the job. Tools like impeller pullers, hose removal tools or a thermometer to accurately read engine temperature can be extremely helpful.

Safety Gear and Best Practices

Do remember, safety comes first. Always wear gloves and safety glasses when working on your engine, especially when dealing with hot or potentially corrosive liquids like coolant.

Preventative Maintenance Practices

Adopting preventative maintenance practices for your cooling system means you’re always one step ahead.

Routine Checks and Balances

Make regular checks of the coolant level, inspecting hoses and belts for wear, and ensuring the water pump is working correctly are basic routines you must follow.

Pre-season and Post-season Inspections

A thorough check of your boat’s cooling system at the beginning and end of each boating season can help identify potential issues early.

Replacing Essential Components before they Fail

Finally, remember that some components, like the impeller or coolant, have a defined lifespan. Replace them periodically as a preventative measure, rather than waiting for evident damage or failure.

Checking and Cleaning the Cooling Channels

Proper inspection and cleaning of the cooling channels are essential for optimal performance.

Inspection Techniques

Look for blockages, corrosion, or damage that could impede the flow of coolant. A visual inspection, paired with temperature checks, can be effective here.

Cleaning Process

To clean the channels, use a coolant system cleaner. Follow the instructions on the product for a successful cleansing process.

When to Seek Professional Assistance

If you find the cleaning or inspection process challenging, it might be time to get a professional involved. Complex issues like inner-engine blockages, corrosion, or severe damage are often best handled by an expert.

Servicing the Water Pump

The water pump is the heart of your cooling system—it needs to be in top shape.

Determining a Water Pump Issue

Symptoms of a failing water pump include overheating, coolant leaks, or a whining noise from the pump pulley.

Step-by-step Guide to Servicing the Water Pump

Servicing the water pump involves removing it, inspecting the parts for wear and tear, replacing faulty components, and reassembling it. Remember to replace the gasket to seal the pump correctly.

Long Term Care for Your Water Pump

For long-term care, make sure to regularly inspect the pump and promptly address any issues. Regular impeller replacement should also be part of your water pump’s preventive maintenance.

Inspecting and Cleaning the Heat Exchanger

The heat exchanger plays a critical role in a closed cooling system. It transfers heat from the coolant to the water from the surrounding environment.

Role and Location of the Heat Exchanger

The heat exchanger, often located near the engine’s front, is like the radiator in your car. It reduces the coolant temperature before it goes back into the engine.

Guidelines for a Thorough Cleaning

A thorough cleaning includes removing the end caps, inspecting the interior for any blockages or damage, and cleaning the tubes using a rod or brush.

When to Replace the Heat Exchanger

If the heat exchanger is extensively damaged, corroded, or reveals persistent issues post-cleaning, it’s time to replace it.

Replenishing or Changing the Coolant

Properly managing the coolant in your closed cooling system is vital.

Choosing the Right Coolant

The right coolant mixes antifreeze and distilled water. Don’t use regular tap water as it could cause mineral buildup.

Draining the Old Coolant

Draining the old coolant starts with removing the drain plug and allowing the coolant to run out into a container.

Procedure for Applying New Coolant

Pour in the new coolant slowly and monitor for any leaks. Once filled, start the engine to circulate the coolant, then do a final top-up as necessary.

Regular Replacement of Impellers

Impellers are key components of your water pump and require regular attention.

Understanding the Role of Impellers

Impellers move the coolant or water around your cooling system. They need to be flexible and resilient to do their job effectively.

How to Know When Replacement is Necessary

Look for signs of deterioration, like cracks or stiffness. Also, a drop in cooling efficiency could suggest a failing impeller. As a rule of thumb, replace the impellers annually.

Steps to Replacing Impellers in your Boat Engine

Impeller replacement involves removing the water pump cover, pulling out the impeller, checking the housing for damage, and inserting a new impeller.

End of Season Care

Winterizing your cooling system is a crucial step in ensuring its longevity.

Steps for Winterizing the Cooling System

Winterizing includes flushing the system with fresh water, draining the coolant, then putting in a mixture of antifreeze and water.

Storage Tips to Preserve the Cooling System

For an extended idle period like winter, store your boat in a dry, frost-free location, away from harsh elements.

Spring Start-up Inspections and Checks

When spring arrives and boating season begins, run a full check-up of the cooling system–from fluid levels, possible leaks, temperature checks, and overall engine performance.

In conclusion, maintaining your boat engine’s cooling system will improve its efficiency, extend its lifespan, and add to the joy of boating. So go ahead, grab your tools and provide the care your boat engine needs. Happy boating!