Ever had that sinking feeling when your boat engine starts sputtering mid-sea? You’re not alone. The “Best Practices for Boat Engine Overhaul and Rebuilds” is all about helping you prevent such situations. It not only addresses issues such as why engines fail and when to plan for an overhaul, but guides you in undertaking a step-by-step engine rebuild process. Replete with tips on engine care and practical solutions, this article becomes your go-to guide to ensure your boat engine delivers top performance whenever you set out for the high seas.

Understanding the Need for Overhaul and Rebuilds

In order to ensure the longevity and optimal performance of your boat, it’s essential to understand the need for regular overhauls and rebuilds. Not only does this proactive approach prevent sudden breakdowns, but it also contributes to overall safety on water.

Recognizing the signs of engine fatigue

The first step in understanding the need for an overhaul or rebuild is recognizing the signs of engine fatigue. If you notice a decrease in performance, for instance, if the engine is not generating as much power as it used to, it might be a signal that some components are worn out. If your boat uses more fuel than usual, it could indicate a problem in the engine’s combustion process. Additionally, abnormal noises or smoke can be a giveaway sign of engine fatigue.

Determining the lifespan of your boat engine

Predicting the lifespan of a boat engine is a crucial aspect of boat maintenance. The lifespan typically depends on several factors such as the quality of the engine, maintenance, frequency of use, and operating conditions. As a general rule of thumb, a well-maintained boat engine could last anywhere from 1,500 to 2,000 hours.

Fault diagnosis and engines’ performance inspection

Fault diagnosis and engine performance inspection are typically conducted by a skilled marine mechanic who can troubleshoot and determine the cause of any engine problem. This could involve checking the spark plugs, cooling system, fuel system, oil, and overall engine condition. This will give a clear picture of what needs to be addressed during the overhaul or rebuild.

Preliminary Steps Before Overhauling or Rebuilding

Before diving into the process of overhauling or rebuilding your boat engine, there are preliminary steps that need to be taken.

Reading and understanding the engine manual

The engine manual is your guide on the composition and workings of your boat engine. Understanding this document will aid in identifying the parts that need attention and how to go about the overhaul or rebuild process.

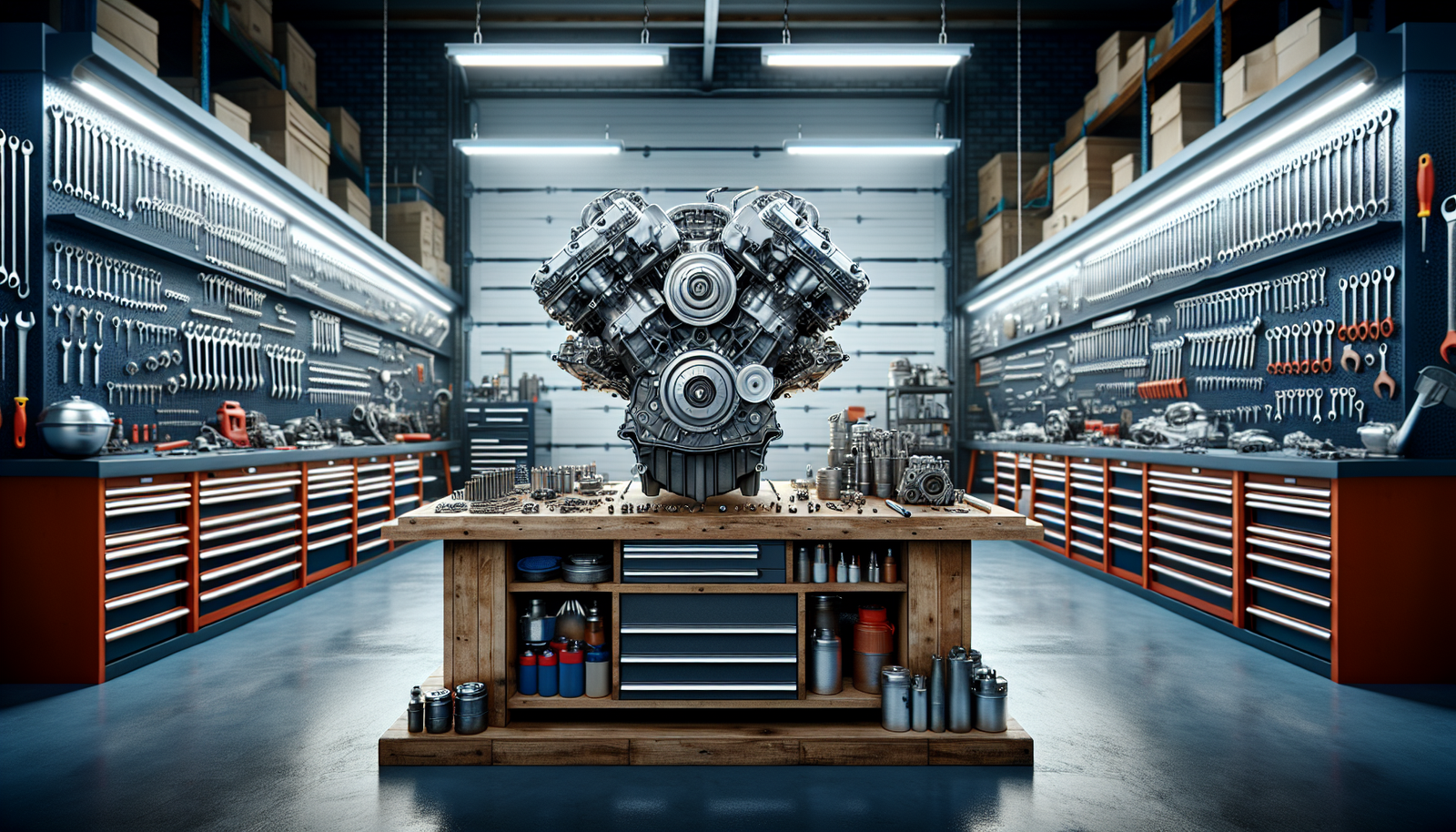

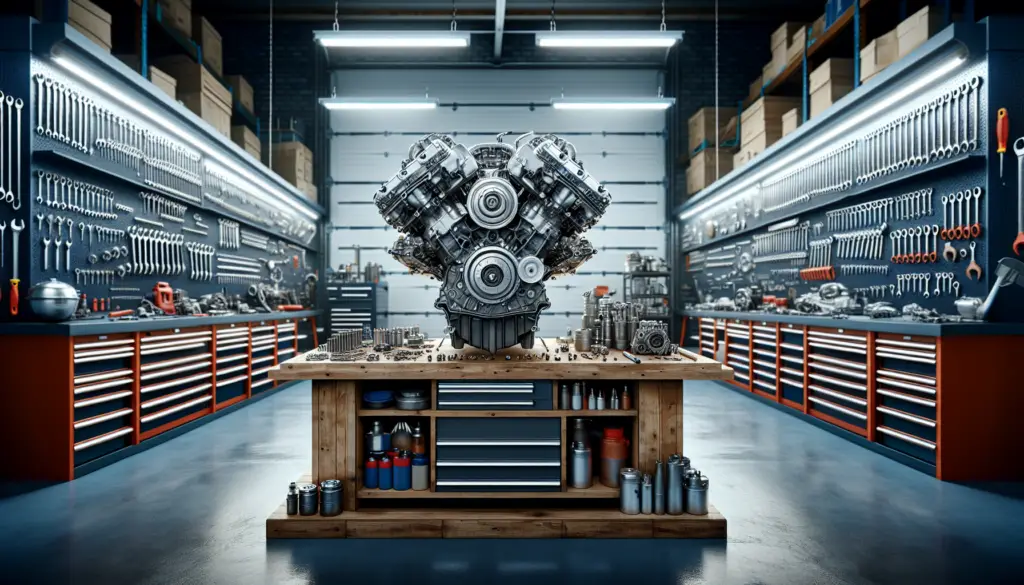

Procurement of necessary tools and parts

Overhauling or rebuilding an engine requires specific tools such as wrenches, screwdrivers, pliers, and other engine-specific tools. Insure you have all these tools before beginning the job.

Creating a clean and organized workspace

Having a clean and organized workspace increases the efficiency of the overhauling or rebuilding process. This includes having containers or bags to store smaller engine parts to avoid loss or mix-up.

Consultation with professionals if needed

Finally, if you aren’t well-acquainted with boat engine mechanics, consulting with a professional mechanic can save time, money, and potential damage.

Disassembly of the Boat Engine

Draining the engine fluids

Firstly, all the engine fluids, including oil and coolant, must be drained. This step is important to prevent any potential damage or corrosion to the internal engine parts.

Removal of external engine parts

Next, removing the external parts of the engine is a crucial step. These parts include items like the carburetor, starter motor, alternator, and exhaust system.

Proper tagging and storage of engine components

As each part is removed, it’s crucial to tag it and store it accordingly. This is a critical step that ensures smooth reassembly and minimizes chances of any part being misplaced or forgotten.

Complete engine take-apart

Lastly, each remaining part of the engine should be taken apart until you reach the bare engine block. This step is necessary for complete inspection and repair of all internal components.

Inspection for Damage and Wear

Once the engine is disassembled, each part needs to be thoroughly inspected for damage and wear.

Assessment of engine parts

Examine each engine part for signs of extreme wear or damage. This should be done meticulously to spot even the slightest signs of damage, which can lead to significant engine problems if not addressed promptly.

Detection of signs of excessive wear

Signs of excessive wear include deep scratches, cylindrical distortion, or extremely worn piston rings. If such signs are detected, those parts need to be replaced.

Evaluation of need for replacement or repair

After assessing each component, you should now be able to determine which parts need to be replaced entirely and which can be repaired.

Cleaning of Engine Parts

Cleaning the engine parts is a critical process during an overhaul or rebuilding.

Methods for effective cleaning

There are several effective methods of cleaning engine parts, ranging from ultrasonic cleaning, to simple hand cleaning using detergents or solvents. The method you choose largely depends on the extent to which the parts are soiled or corroded.

Avoidance of damaging sensitive parts

While cleaning, care has to be taken to avoid damaging the delicate parts of the engine. It’s also crucial to thoroughly dry each part to prevent rusting.

Preparation for reassembly

Once cleaning is done, the various engine parts should be lubricated in preparation for reassembly. This helps protect the engine parts from damage when the engine is started after reassembly.

Overhauling the Boat Engine

Replacement of worn parts

The overhauling process starts with the replacement of all the worn parts identified during inspection. This should be done carefully, making sure each replacement part fits perfectly in its respective place.

Reassembly process and preventive measures

The reassembly process, much like the disassembly process, should be done methodically. Follow the engine’s manual for guidance and be sure to double-check each step to avoid any mistakes. During this process, preventive measures such as applying anti-seize compound on relevant parts should be taken.

Balancing and aligning the engine

Upon completion of the reassembly, it’s important to ensure that the engine is balanced and well-aligned. An unbalanced engine can lead to excessive vibration, which hastens wear and tear, while misalignment can cause operational failures.

Routine trials to ensure smooth operation before full usage

After reassembly, routine trials should be conducted to ensure the engine operates smoothly. This also helps identify potential leaks and alignment problems.

Rebuilding the Boat Engine

Steps in engine rebuild

While every engine rebuild varies, common steps include inspecting, cleaning, and replacing worn parts, just as you would with an overhaul. A rebuild, however, typically requires replacing more parts, such as pistons and valves, and may also involve resurfacing parts.

Best strategies for rebuilding

One of the best strategies for rebuilding a boat engine is by working systematically, based on the guidance provided in the workshop manual. Always aim to improve engine efficiency, power, reliability and longevity.

Significant parts to be addressed during rebuilding

During a rebuild, significant parts like pistons, bearing, valves, spark plugs, injectors and the engine block itself usually receive proper attention. Such parts are usually replaced or reconditioned to restore the engine’s performance.

Finalizing the Overhaul or Rebuild

Checking for leaks and potential issues

After the reassembly or rebuild, check for leaks and any potential issues that may have arisen during the process. Check the oil, coolant, and fuel systems for any leaks.

Thorough testing of engine

A thorough test of the engine should be conducted. This allows you to confirm that everything was reassembled correctly and that the engine is performing as expected.

Confirmation of successful operation

Finally, confirm successful operation of the engine. This is done by observing normal engine temperature, listening for abnormal noises, and looking for indications of exhausted gasses or excessive vibrations.

Maintenance Tips Post-Overhaul or Rebuild

Regular checks and maintenance

Regular checks post-overhaul or rebuild are essential to retain your engine’s performance. Regular oil changes, coolant checks, and air filter changes are part of routine maintenance.

Maintaining a log of performance

Keeping a logbook detailing every maintenance task performed and the general performance of the engine can be priceless in troubleshooting future issues.

Proper storage and handling of the boat engine

Proper storage and handling of the boat engine extends the life of the engine. When not in use, store in a dry place and cover the engine to protect it from dust and moisture.

Health and Safety Measures during Engine Overhaul and Rebuilds

Proper use of tools and machinery

When overhauling or rebuilding your boat engine, always ensure that you’re using the tools and machinery correctly. Inappropriate use of tools can lead to accidents, damage to the engine parts, and unproductive work.

Safe handling of engine parts and fluids

It’s essential to safely handle engine parts and fluids. Many engine fluids are toxic and can be hazardous to your health if they come into contact with your skin or if they are ingested or inhaled.

Precautions against common accidents and emergencies

Adhere to safety measures like using protective equipment and working in a well-ventilated area. Also, be prepared for emergencies by having a first-aid kit handy and ensuring you have easy access to a phone in case of an accident.