As a devoted boat owner, your prized possession deserves diligent care to ensure it continues to serve you faithfully, particularly through the harsh winter months. This article presents some of the most effective strategies to winterize your boat engine’s cooling system, ensuring it’s ready to perform when the warmer months return. Here, you’ll receive expert tips and step-by-step guidance on the essential precautions necessary to safeguard your boat during winter. So buckle up, prepare your notes, and get set to give your boat the thorough winterizing treatment it needs!

Understanding the Importance of Winterizing

Winterizing your boat is an essential practice that not only impacts the performance of your vessel but also greatly extends its lifespan. This article will help you understand the importance and procedure for winterizing your boat’s engine cooling system.

Need for Winterization

As a boat owner, it is crucial you appreciate the importance and value of winterization. This process, when performed annually, can prevent significant damage to your boat’s engine that can be caused by freezing temperatures. Winterization ensures that your vessel is ready for use when the boating season begins anew.

Effects of Freezing on Boat Engines

Freezing temperatures can have a significant impact on boat engines. When the water inside an engine freezes, it expands. This expansion can cause engine parts to crack or even shatter completely. Damage from freezing can be expensive to repair and can sometimes lead to complete engine failure.

Preventing Damage and Subsequent Repair Costs

By taking adequate steps towards winterizing your boat engine, you can avoid the need for costly repairs completely. Winterization effectively helps minimize the risk of freeze damage in the engine’s cooling system. Thus, it is an investment that is well worth the time and effort involved.

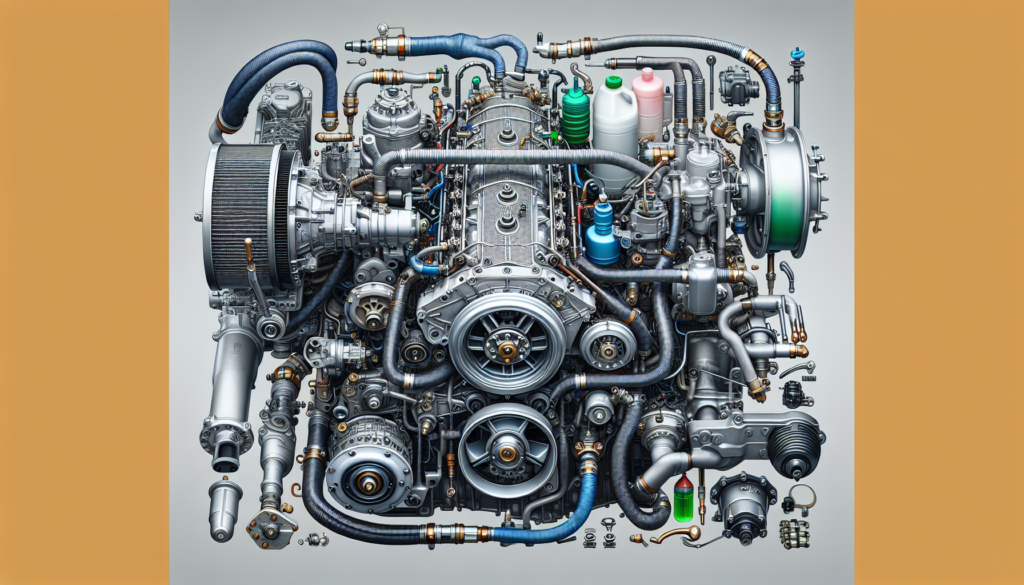

Getting to Know Your Boat’s Cooling System

Before embarking on the winterization process, it’s beneficial to understand your engine’s cooling system. Most marine engines use one of two types of cooling systems: raw water and closed cooling systems.

Function of the Cooling System

The cooling system in boats regulates engine temperature to prevent overheating, thus it plays a vital role in engine performance. It does this by circulating a coolant (either sea water or a coolant fluid) through the engine, absorbing the excess heat generated by the engine.

Understanding Raw Water Cooling Systems

A raw water cooling system, as the name suggests, uses the naturally cold seawater as a coolant to regulate engine temperature. The seawater is drawn into the engine, where it absorbs heat before being expelled overboard.

Understanding Closed Cooling Systems

On the other hand, a closed cooling system is a little more complex. It uses a heat exchanger to cool the engine. A coolant fluid circulates within a closed loop system, absorbing the heat from the engine. This heated coolant then passes through a heat exchanger, where it is cooled by raw water.

Pre-Winterization Checks

Before you start the winterization process, there are a few pre-winterization checks that should be performed. This ensures that any prevailing conditions or damages are dealt with before the winter sets in.

Assessing the Condition of the Engine

Start by assessing the overall condition of your engine. Keep an eye out for any visual signs of wear or damage, check the engine oil color and level, and also observe if there are any abnormal sounds when the engine is running.

Checking for System Leaks or Damages

Look for any leaks or damages within the cooling system. Leaks can be easily identified by puddles or traces of coolant around the engine. Also, inspect the hoses and clamps to ensure they are in good condition.

Confirming the Functioning of the Thermostat

Lastly, confirm that the thermostat is functioning properly. A stuck or malfunctioning thermostat can lead to overheating in the engine, resulting in expensive distress and damages.

Draining the Cooling System

Once the pre-checks have been conducted, the first significant step of winterization is to drain the cooling system.

Significance of Draining the System

Draining the cooling system ensures that there is no water left in the engine or its components. This is crucial in preventing freeze damage during the winter.

Steps in Draining Raw Water Cooling Systems

For raw water cooling systems, locate the drain plugs on the heat exchanger, engine block and exhaust manifold. Remove these plugs and allow the water to drain out completely.

Steps in Draining Closed Cooling Systems

For closed cooling systems, the process is a little different. You’ll need to drain both the raw water side and the coolant from the system. Locate the appropriate plugs and drain the coolant into a clean container for later disposal.

Cleaning the Cooling System

After draining the system, it’s critical to thoroughly clean it. This removes any sediment or deposits that could impede the cooling system’s efficiency.

The Role of Cleaning in Winterization

Cleaning is paramount in preventing the buildup of mineral deposits or rust within the system. These deposits can obstruct the coolant flow, leading to overheating and eventual engine failure.

Cleaning Supplies and Materials

You can use a commercial engine coolant system cleaner for this process. Also, a hose, a bucket, and some rags would come in handy to clean the spills.

A Step-by-Step Guide to Cleaning the Cooling System

Once you have your cleaning supplies ready, you can fill the cooling system with your cleaning solution as per its instructions. Let it sit for some time and then drain the system again. Rinewash thoroughly with fresh water to ensure no cleaning residue is left that could contaminate the new coolant.

Flushing the Cooling System

Flushing is another critical step in the winterization process. It helps remove any remaining deposits from the cooling system.

Why Flushing is Essential

Flushing the cooling system with clean fresh water helps eliminate any residual contaminants that may not have been dislodged during the cleaning process. This intensifies the overall cleaning outcome.

How to Flush a Raw Water Cooling System

To flush a raw water cooling system, attach a hose to the raw water intake and run fresh water through the system. Ensure the water runs out clear when draining to confirm it’s fully flushed.

How to Flush a Closed Cooling System

For a closed cooling system, fill the system with fresh water and run the engine for a few minutes. Then drain the system and repeat the process if needed until the drained water runs clear.

Applying Antifreeze

Applying antifreeze is a critical step in winterizing your boat’s engine. It serves a two-fold purpose: it inhibits freezing and also prevents corrosion within the cooling system.

The Need for Antifreeze

Antifreeze is crucial in preventing the remaining water in the system from freezing and cracking the engine parts. Moreover, it also adds a protective layer to the interior surfaces of the system, combating the formation of rust and corrosion.

Choosing the Right Type of Antifreeze

Ensure you choose a marine-grade, non-toxic, propylene-based antifreeze for your boat. This type is usually pink or green in color and safe for the marine environment.

Procedure for Applying Antifreeze in the Cooling System

To apply antifreeze, fill the system with it and run the engine for a few minutes until you see antifreeze being expelled out of the engine. Make sure you have enough antifreeze to fill all parts of the system by calculating your system’s capacity before this procedure.

Inspecting Cooling System Components

Post winterization, it’s sensible to inspect a few key components to ensure that they are in good working condition.

Checking the Pump and Belt

Inspect the water pump to ensure it’s functioning properly as it plays a crucial role in cooling the engine. Also, check the water pump drive belt for any signs of wear or cracking.

Inspecting the Hoses and Clamps

Inspect all hoses and clamps within the system for signs of wear or breakage. A broken or ruptured hose can cause a cooling system failure, which can result in engine overheating.

Examining the Heat Exchanger or Cooler

If your boat uses a closed cooling system, make sure to inspect the heat exchanger or cooler. Look for any signs of corrosion or salt buildup. If any is found, take measures to clean it.

Addressing Minor Repairs and Replacements

Occasionally there may be minor elements that need repair or replacement after the winterization process.

Identifying Common Parts that Need Replacement

Typically, components like hoses, clamps, and belts are the ones most likely to need replacements after a few seasons of use. Always have a few spare ones handy!

How to Replace the Failing Elements

To replace a failing component, simply remove the failing element and install a fresh one. Ensure you reattach everything securely to maintain the integrity of the cooling system.

Find Out When to Seek Professional’s Help

While minor issues can generally be solved at your end, if you come across anything significant, it’s advisable to seek professional help. Some problems require expert skills to resolve and misguided attempts to fix them on your own can sometimes cause more harm than good.

Maintaining Boat Engine After Winterization

Once the winterization process is complete, it’s important to maintain your boat engine properly throughout the winter season.

Proper Storage of Your Boat

Ensure your boat is correctly secured in a well-ventilated and dry place. Regularly check the antifreeze concentration to ensure optimal freeze protection.

Regular Checks During the Offseason

Perform regular checks during the offseason to ensure that everything’s in order. Monitor for any moisture build-up or unexpected leaks. Also, it’s good to run the engine for a short while every few weeks to circulate the antifreeze.

Pre-Start Checks for When the Season Begins Anew

When the boating season begins, remember to perform a pre-start check. This involves replacing the drain plugs, checking fluid levels, observing for any leaks, and then initially running the engine at a low speed.

Winterizing may seem like a daunting task, but when performed correctly, it can save you from expensive and time-consuming repairs. In the end, a winter-ready engine ensures a hassle-free start to the next boating season!