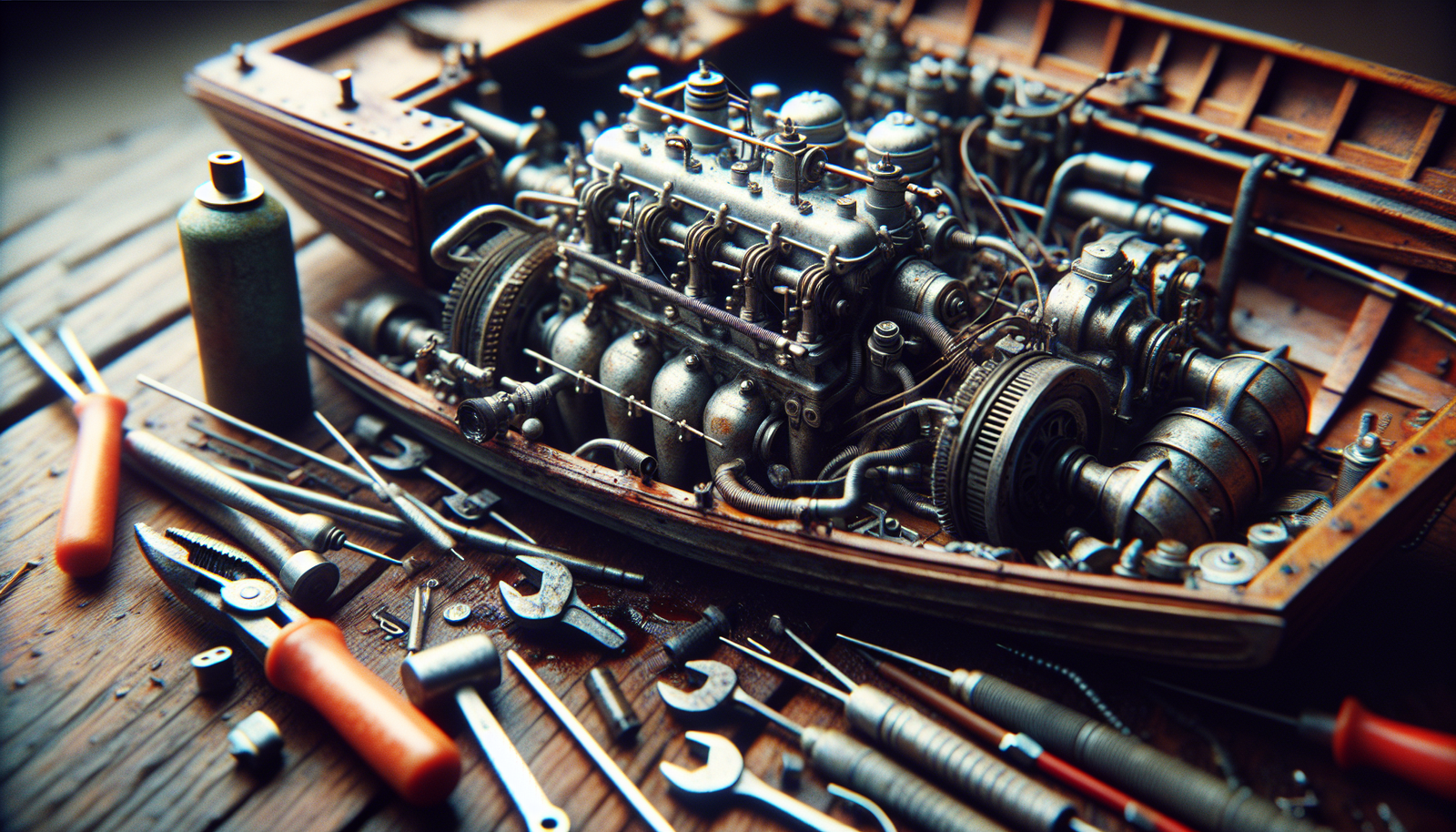

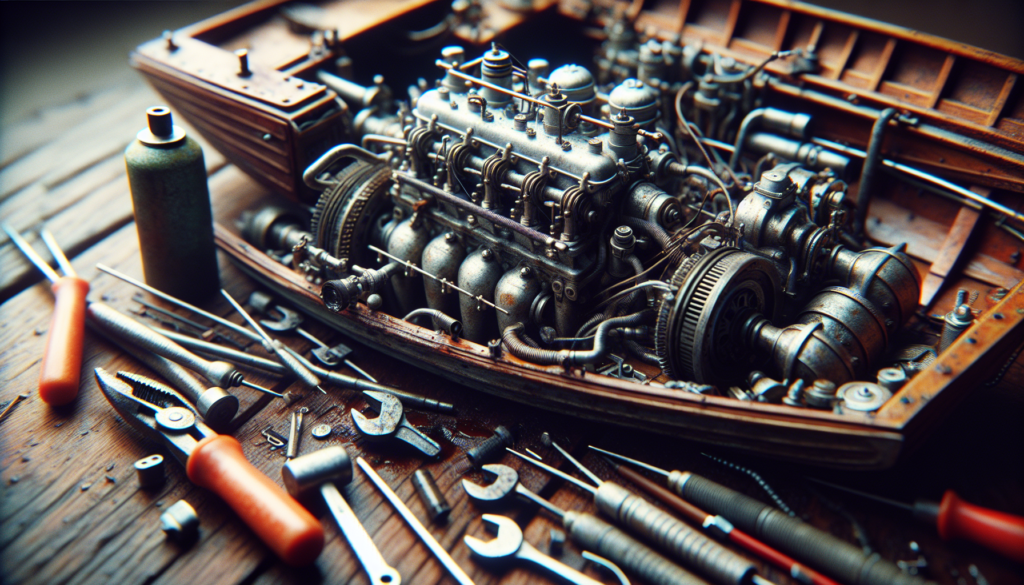

As the proud owner of an older boat model, knowing how to maintain its engine is essential for ensuring its longevity and smooth operation. In this article, “Common Boat Engine Maintenance Techniques For Older Models,” you’ll discover practical strategies and tactics that are specific to older marine engines. The information is set to arm you with the skills necessary to keep your boat running at peak efficiency for many more years. From routine procedures to more advanced techniques, you’re about to unlock the secrets to prolonging the life of your boat engine.

Understanding Older Boat Engines

Before attempting any maintenance procedures on your boat engine, it’s crucial to understand it fully. Boat engines can differ greatly depending on their age. For all the advances in technology and engineering, older boat engines possess a charm of their own and may still operate smoothly if properly cared for. Knowledge about both old and new models will empower you for the proper care and maintenance they deserve.

Differentiating Older Engines From Newer Models

There is a stark contrast between newer high-tech engines and their older counterparts. The advent of technology shifted the focus to sleeker, computer-based models with advanced troubleshooting systems. Newer models rely heavily on electronics and technology. On the flip side, older engines are more mechanical in nature. They are easier to understand and repair at a basic level. While these may lack the efficiency of their newer counterparts, their simplicity has an appealing lure for boat owners.

Unique Characteristics of Older Boat Engines

Older boat engines come with their unique set of features and complexities, such as carbureted fuel systems rather than fuel-injected systems found in modern engines. They might also not have sophisticated computer systems for diagnosing issues. However, these engines tend to be robust, resilient and more forgiving of neglect than the finicky, high-performance engines of today. Many of these older engines are quite “user friendly” and easy to work on, adding to their desirability among vessel owners.

Maintenance Considerations Specific to Older Engines

Maintaining an older boat engine can be different than caring for a newer model. They often require frequent adjustments and inspections to keep things running smoothly. Their mechanisms may wear out more quickly, requiring more frequent replacement of parts. Furthermore, corrosion poses a more significant risk due to their age, making regular corrosion monitoring and prevention vital to their longevity.

Routine Inspection of Boat Engines

Regular inspections of your engine can help prevent problems before they escalate. This is particularly true for older models.

Establishing a Regular Inspection Schedule

It’s good practice to establish regular engine checks, providing you with peace of mind that everything is functioning correctly. Depending on the use of the boat and the age of the engine, a monthly or quarterly inspection is advisable. However, always consult your engine’s manual for recommended inspection intervals.

Key Components to Inspect

Among the parts to inspect are the cooling system, exhaust system, belts, hoses, and electrical components. Be sure to check for leaks, corrosion, wear, or any unusual noises when the engine runs. Parts like fuel filters, spark plugs and impellers tend to require changes more frequently. It’s also wise to inspect the engine oil for any signs of water or contaminants.

Spotting Signs of Potential Trouble Early

Routine inspections allow you to spot anomalies early, such as changes in engine performance or odd sounds, among others. This could be something simple such as a clogged filter or something more serious that needs professional attention. The point is to catch these potential issues early before they become expensive repairs or replacements.

Fluid Checks and Changes

Engines, like any other mechanical machinery, depend on different fluids for their smooth operation.

Importance of Regular Oil Changes

Just like in a car, regular oil changes are essential for a boat engine’s longevity. Old oil can reduce performance, damage parts, and eventually lead to major engine failure. Depending on your usage and environment, oil changes are typically required every 50-100 hours of operation for older boat engines.

Checking Coolant and Changing When Necessary

Coolant plays a crucial role in preventing your engine from overheating. Regularly checking your coolant level, color, and condition can help spot potential trouble early. It’s good practice to flush and replace your coolant every 1-2 years or as suggested in your engine’s manual.

When and How to Change the Transmission Fluid

Keeping a check on your transmission fluid is also integral to your engine’s health. If the fluid appears cloudy or has a burnt smell, it’s time for a change. Make sure to consult your owner’s manual for the correct fluid type and recommended change interval.

Fuel System Maintenance

Ensuring a clean, efficient fuel system is essential for the overall health and performance of your boat’s engine.

Proper Fuel Usage and Storage

Usage of the correct type and quality of fuel is important. Fuel should be stored correctly, in an approved container, and used before it gets too old. Stale or contaminated fuel can damage your engine.

Cleaning Fuel Injectors

Fuel injectors can become clogged over time, affecting engine performance. Cleaning your fuel injectors can improve engine efficiency and longevity.

Replacing Fuel Filters

Fuel filters should be changed regularly to ensure only clean fuel reaches the engine. Replacing them can prevent potential damage from contaminants.

Engine Cleaning and Corrosion Control

Engine cleaning and corrosion control are critical for older boat engines.

Keeping the Engine Clean to Prevent Damage

Keeping the engine clean helps you spot issues like leaks, corrosion, or worn components more easily. Moreover, a clean engine is less likely to overheat and generally performs better.

Identifying and Addressing Corrosion

Corrosion, particularly saltwater corrosion, can severely damage your engine parts over time. Regular inspection for signs of corrosion and prompt treatment can extend your engine’s lifespan.

Methods to Protect Against Saltwater Damage

Application of protective coatings, use of sacrificial anodes, and regular freshwater flushing are effective methods to combat saltwater corrosion.

Electrical System Upkeep

The electrical system of your boat is its lifeline.

Caring for Starting or Ignition System

Regular inspection and care of your starting or ignition system ensures your boat starts when you need it to. This includes checking your battery, breaker points, spark plugs, and wires.

Inspecting and Maintaining the Alternator

Your alternator charges your battery. Regular inspections will prevent unexpected failures, while routine maintenance ensures it performs at its best.

Preventing Electrical System Failure

Proactive care like cleaning connections, checking wires and fuses, and servicing the alternator and battery can help avoid electrical system failure.

Propeller and Drive Shaft Maintenance

Your propeller and driveshaft are critical elements of your boat.

Checking the Propeller for Damage

Even minor damage to your propeller can impact the performance and fuel efficiency of your boat. Regular checks and timely repairs or replacements are essential.

Lubricating the Drive Shaft

Regular lubrication of the drive shaft prevents wear, corrosion, and improves performance.

Repairing or Replacing Faulty Propellers

Whenever your propeller shows signs of damage or wear, contemplate repair or replacement, depending on the extent of the damage.

Exhaust System Checks

A healthy exhaust system is integral to your boat’s performance.

Spotting Exhaust Leaks

Regular checks for exhaust leaks help ensure the safety and performance of your boat.

Maintaining the Manifold and Risers

The exhaust manifold and risers require regular inspection and maintenance to prevent overheating, which can cause significant damage to the engine.

Prevention and Repair of Exhaust Blower Problems

Regularly checking the efficiency of your exhaust blower and addressing any problems promptly can prevent potential issues down the line.

Belt, Hose, and Clamp Inspections

Belts, hoses, and clamps play crucial roles in your boat’s operation.

Replacing Aged or Worn Belts

Regularly inspect belts for signs of wear or aging. Replace them promptly to prevent a breakdown.

Checking Hoses for Leaks or Weak Spots

Routinely check hoses for leaks, weak spots, or signs of aging. Replace them immediately if they show signs of damage.

Ensuring Clamps Are Secure and Free from Rust

Inspect the clamps for safety and integrity. Replace any corrupted or loose clamps promptly.

Professional Help and When to Seek It

There are times when you might reach the limits of your capabilities or comfort zone.

Identifying Issues Beyond DIY

Complex problems, extensive repairs, or difficult installations should be entrusted to a professional mechanic.

Finding a reputable marine mechanic

Building a relationship with a reputable marine mechanic can be invaluable for the care and longevity of your boat engine.

Scheduling Regular Professional Inspections

In addition to your regular inspections, having a professional check out your engine at least once a year can determine holistic engine health and catch issues that may not be visible to the untrained eye.

Maintaining a boat, particularly an older model, may sound daunting but it’s largely about diligence, regular checks, and smart care. You can handle the majority of the maintenance, but don’t forget that seeking professional help can be a wise decision too.