Have you ever wondered how to make your car engine last longer and perform better? In this article, we will explore the benefits of engine customization and how it can increase the longevity and durability of your vehicle. By making some simple modifications to your engine, you can enhance its performance, improve fuel efficiency, and ensure that it stands the test of time. Whether you are a car enthusiast or simply want to get the most out of your vehicle, engine customization is a worthwhile investment that can have a significant impact on the overall lifespan of your engine. So, let’s dive in and discover the secrets to increasing longevity and durability through engine customization!

Choosing the Right Engine Parts

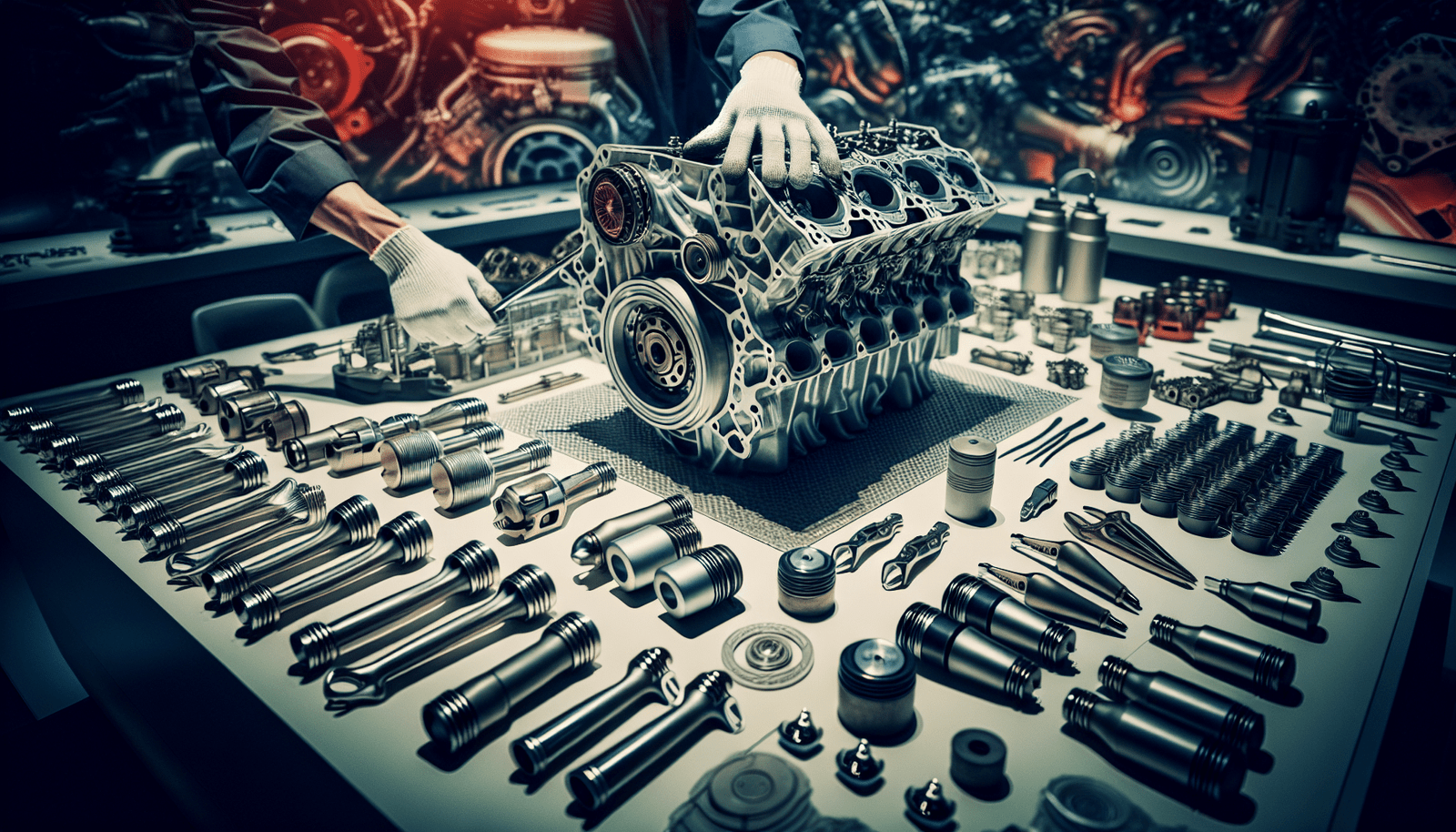

Understanding the Importance of Engine Parts

When it comes to enhancing the performance and durability of your vehicle’s engine, choosing the right engine parts is crucial. Engine parts play a vital role in ensuring optimum performance, longevity, and reliability of your engine. Each component performs a specific function and contributes to the overall functionality of the engine. Understanding the importance of engine parts will enable you to make informed decisions when selecting the best parts for your vehicle.

Researching the Best Engine Parts for Your Vehicle

Before diving into the world of engine customization, it is essential to thoroughly research and identify the best engine parts for your vehicle. Different vehicles have varying engine specifications and requirements, which is why it is crucial to select parts that are compatible with your vehicle’s make and model. Spend time researching reputable brands and manufacturers known for producing high-quality engine parts. Customer reviews and expert opinions can also provide valuable insights into the performance and durability of specific parts.

Considering Performance vs. Durability

When choosing engine parts, it is essential to strike a balance between performance and durability. Performance-focused parts can significantly enhance your engine’s power and efficiency but may sacrifice longevity. On the other hand, parts that prioritize durability may not provide the same level of performance gains. Consider your specific needs and requirements. If you are looking for improved acceleration and power, performance-oriented parts might be the way to go. However, if longevity and reliability are your main concerns, opting for durable parts would be a smarter choice.

Consulting with Experts or Mechanics for Recommendations

If you feel overwhelmed or unsure about which engine parts to choose for your vehicle, consulting with experts or mechanics can prove highly beneficial. They possess extensive knowledge and experience in engine customization and can provide valuable recommendations based on your vehicle’s needs and your desired outcomes. Experts can help guide you through the vast array of options, ensuring that you make the right choices for your engine. They can offer insights into compatible parts, performance gains, and potential issues to consider, helping you make well-informed decisions.

Proper Engine Maintenance

Following Regular Maintenance Schedule

Proper engine maintenance is fundamental to maximizing longevity and durability. Following a regular maintenance schedule is essential to keep your engine running smoothly and efficiently. Consult your vehicle’s owner’s manual or speak to a mechanic to determine the recommended maintenance intervals for various engine components. Regular maintenance tasks should include oil changes, filter replacements, belt and hose inspections, fluid level checks, spark plug replacements, and general cleaning.

Changing Engine Oil and Filter

One of the most critical aspects of engine maintenance is regularly changing the engine oil and filter. Engine oil lubricates the moving parts within the engine, reducing friction and heat generation. Over time, engine oil becomes contaminated with dirt, debris, and combustion by-products, compromising its effectiveness. Regularly changing the oil and filter ensures that the engine continues to receive the necessary lubrication and protection it needs to function optimally.

Inspecting and Replacing Belts and Hoses

Belts and hoses play a crucial role in the engine’s operation by powering various components and carrying fluids. Over time, belts can become worn, cracked, or stretched, while hoses can develop leaks or bulges. Regularly inspecting and replacing belts and hoses reduces the risk of unexpected failures, which can lead to engine damage or breakdowns. Replace any belts or hoses that show signs of wear or deterioration to maintain the integrity and functionality of your engine.

Checking and Topping off Fluid Levels

Fluids such as coolant, brake fluid, power steering fluid, and transmission fluid are vital for various engine components to function properly. Regularly checking the fluid levels and topping them off as necessary ensures that your engine remains cool, well-lubricated, and efficient. Insufficient fluid levels can lead to overheating, increased friction, and potential damage to vital engine parts. Regular maintenance should include routine fluid level checks to prevent any long-term issues.

Keeping the Engine Clean and Free of Debris

Maintaining a clean engine is not only aesthetically pleasing but also critical for its longevity and performance. Dust, dirt, and debris can accumulate over time, hampering the engine’s cooling capabilities and causing unnecessary strain on components. Regularly cleaning the engine compartment and removing debris is essential to promote proper airflow and prevent potential overheating. Use a gentle cleaner and soft brushes or cloths to avoid damaging delicate engine components while cleaning.

Enhancing Engine Cooling

Upgrading the Radiator

The radiator plays a vital role in regulating the engine’s temperature by dissipating heat generated during operation. Upgrading to a high-performance radiator can significantly improve the cooling efficiency of your engine. High-performance radiators are designed to handle higher heat loads and offer better cooling capabilities than stock radiators. When selecting a radiator, consider factors such as material quality, size, and cooling capacity to ensure it matches your engine’s requirements.

Installing High-Performance Cooling Fans

Cooling fans are responsible for circulating air through the radiator, assisting in heat dissipation. upgrading to high-performance cooling fans can help improve the airflow and cooling efficiency of your engine. High-performance fans often have increased blade size, more efficient motors, and superior airflow capabilities. These fans can ensure that the engine stays within safe temperature limits, especially during demanding conditions or heavy load situations.

Using a Coolant Additive

Adding a coolant additive to your engine’s cooling system can provide additional protection against overheating and corrosion. Coolant additives are designed to improve the heat transfer properties of the coolant, allowing for better temperature regulation. They also help prevent the formation of rust and scale inside the cooling system, which can impede coolant flow and reduce cooling efficiency. Consult the manufacturer’s guidelines to select the appropriate coolant additive for your engine.

Monitoring Engine Temperature

To effectively manage engine cooling, it is crucial to monitor the engine temperature regularly. Installing an aftermarket temperature gauge or utilizing your vehicle’s existing temperature gauge can help you keep an eye on the engine’s temperature level. Monitoring the temperature allows you to detect any abnormal fluctuations or overheating issues promptly. If you notice consistent high temperatures, it may indicate a problem with the cooling system that should be addressed promptly.

Ensuring Proper Airflow

To enhance engine cooling, optimizing the airflow around the engine is essential. Ensure that there are no obstructions around the radiator, such as leaves, debris, or aftermarket modifications that impede airflow. Additionally, consider upgrading or adding air ducting components to direct cool air more efficiently towards the radiator. Maximizing airflow helps maintain lower operating temperatures, resulting in improved performance, longevity, and overall engine health.

Optimizing Fuel Delivery

Choosing the Right Fuel Pump

The fuel pump is responsible for delivering the right amount of fuel to your engine’s combustion chambers. When upgrading your engine, it is crucial to select a fuel pump that can handle the increased fuel demands. High-performance fuel pumps are designed to provide a consistent and reliable fuel supply under high-stress conditions. Choose a fuel pump that matches the fuel requirements of your engine, ensuring proper fuel delivery at all times.

Installing Fuel Injectors or Carburetors

Fuel injectors or carburetors are responsible for delivering fuel into the engine’s combustion chambers. Upgrading to fuel injectors or carburetors that are appropriately sized for your engine can enhance fuel delivery and atomization, leading to improved performance and efficiency. Fuel injectors provide precise fuel metering, while carburetors offer simplicity and adjustability. Consider your preferences and engine’s requirements when choosing between these options.

Upgrading Fuel Lines and Filters

Ensuring a clean and consistent fuel supply is crucial for optimal engine performance and longevity. Upgrading fuel lines and filters can help prevent contaminants from reaching the engine and potentially causing damage. High-performance fuel lines are designed to withstand higher pressures and flow rates, while performance fuel filters are more effective at trapping and removing particles. Appropriate fuel line and filter upgrades can help maintain fuel system cleanliness and prevent fuel-related issues.

Considering Fuel Additives

Fuel additives can offer additional benefits to your engine’s fuel system. They can improve fuel stability, prevent corrosion, and enhance combustion efficiency. Some additives also claim to provide cleaning properties, keeping fuel injectors or carburetors free from deposits and carbon buildup. When considering fuel additives, research different options and select those that are compatible with your fuel and engine requirements. Follow the manufacturer’s recommendations for proper usage and dosage.

Regularly Cleaning and Maintaining Fuel System

Routine cleaning and maintenance of the fuel system are essential to ensure its longevity and optimal performance. Over time, fuel injectors or carburetors can become clogged or restricted due to the accumulation of deposits or varnish. Regularly cleaning or professionally servicing these components can help maintain their efficiency and prevent fuel flow disruptions. Additionally, periodically inspect and clean the fuel tank, fuel lines, and fuel filters to remove any accumulated debris or contaminants.

Upgrading Ignition System

Installing High-Performance Spark Plugs

Spark plugs are vital for igniting the air/fuel mixture within the engine’s combustion chambers. Upgrading to high-performance spark plugs can improve combustion efficiency, resulting in better fuel economy, increased power, and smoother operation. High-performance spark plugs often have advanced electrode designs and materials that facilitate a stronger and more consistent spark. Consider the heat range and electrode type recommended for your engine to select the most suitable spark plugs.

Upgrading Ignition Coils or Distributor

Ignition coils or distributors are responsible for transmitting the electrical voltage to the spark plugs, enabling combustion. Upgrading to high-performance ignition coils or distributors can provide more reliable and powerful sparks, enhancing overall ignition performance. Advanced ignition systems offer features such as multiple sparks, higher energy output, or improved voltage distribution, leading to improved engine performance. Research different options and select the ignition components that align with your engine’s ignition system requirements.

Using Electronic Ignition Systems

Electronic ignition systems offer several advantages over traditional mechanical systems. They provide precise timing control, improved spark timing, and enhanced combustion efficiency. Upgrading to an electronic ignition system can result in better fuel economy, increased power output, and reduced emissions. Electronic ignition systems are available in various configurations, such as distributorless ignition systems (DIS) or coil-on-plug (COP) systems. Consult with experts or mechanics to determine the best electronic ignition system for your engine.

Ensuring Proper Timing

Proper ignition timing is crucial for optimal engine performance and longevity. Incorrect timing can lead to poor combustion, reduced power, increased fuel consumption, and potential engine damage. Regularly check and adjust the ignition timing according to your engine’s specifications or recommendations provided by the manufacturer. Proper timing ensures that the spark occurs at the precise moment for combustion, maximizing power output and minimizing potential issues.

Regularly Checking and Adjusting Ignition Settings

Continuously monitoring and adjusting the ignition settings is essential to ensure that your engine is running at its best. This includes checking and adjusting spark plug gaps, ignition timing, and ignition coil performance. Regularly inspecting these components and making necessary adjustments can optimize the ignition system’s performance, leading to improved overall engine efficiency and reliability. Follow the manufacturer’s guidelines and consult with professionals if unsure about the proper ignition settings for your engine.

Improving Air Intake

Using High-Flow Air Filters

Air filters play a crucial role in maintaining clean air intake, preventing harmful contaminants from entering the engine. Upgrading to high-flow air filters can improve airflow and filtration efficiency, allowing for better engine performance. High-flow air filters are designed to deliver more air to the engine while still effectively capturing particles. They offer less restriction compared to stock filters and can enhance throttle response and power output. Consider your driving conditions and requirements when selecting the appropriate high-flow air filter for your engine.

Installing Cold Air Intake Systems

Cold air intake systems can significantly enhance the engine’s performance by increasing the airflow and reducing the intake air temperature. These systems replace the stock air intake with a more efficient setup that draws cooler air from outside the engine compartment. Cooler air is denser, leading to improved combustion and power output. Cold air intake systems are available in different designs, such as short ram intakes or cold air intakes. Research and select a system that is compatible with your vehicle’s make and model.

Considering Turbochargers or Superchargers

Turbochargers and superchargers are forced induction systems that deliver compressed air to the engine, resulting in increased power output. These systems force more air into the combustion chambers, allowing for improved combustion and higher horsepower. Turbochargers use exhaust gases to drive a turbine, while superchargers are belt-driven and provide instant boost. Adding a turbocharger or supercharger to your engine can deliver significant performance gains. However, installation and tuning should be done by experts to ensure proper compatibility and functionality.

Optimizing Air/fuel Mixture

Achieving the right air/fuel mixture is critical for efficient combustion and optimal engine performance. Upgrading the air intake system may require adjustments to the fuel delivery system to maintain the proper air/fuel ratio. Consult with experts or mechanics to determine if recalibration or tuning of the engine’s fuel injection or carburetor system is necessary. Proper optimization of the air/fuel mixture ensures clean and efficient combustion, resulting in improved power, fuel economy, and overall performance.

Cleaning and Maintaining Air Intake Components

Keeping the air intake components clean and well-maintained is essential for maximizing engine performance and longevity. Over time, dirt, dust, and debris can accumulate in the air intake system, restricting airflow and potentially causing engine issues. Regularly inspect and clean the air filter, intake manifold, throttle body, and any other components within the air intake system. Use appropriate cleaning agents and follow manufacturer guidelines to ensure proper cleaning without damaging sensitive parts.

Upgrading Exhaust System

Installing High-Performance Headers

Headers are an essential component of the exhaust system, responsible for improving exhaust gas flow and reducing backpressure. Upgrading to high-performance headers can enhance the engine’s performance by optimizing exhaust gas evacuation. High-performance headers are designed with larger diameter tubing, smooth bends, and specific lengths to maximize exhaust flow efficiency. Consider factors such as material quality, exhaust system design, and compatibility with your engine when selecting headers for your vehicle.

Upgrading Catalytic Converters

Catalytic converters play a crucial role in reducing harmful emissions by converting pollutants into less harmful substances. When upgrading the exhaust system, consider upgrading to high-performance catalytic converters. High-performance catalytic converters are designed to offer increased flow rates while still effectively reducing emissions. They provide better exhaust gas evacuation, improving engine performance without compromising environmental concerns. Research the regulations and requirements in your location to ensure compliance with emission standards.

Choosing Performance Exhaust Pipes and Mufflers

Exhaust pipes and mufflers have a significant impact on the engine’s performance and sound. Upgrading to performance exhaust pipes and mufflers can improve exhaust gas flow, reduce restrictions, and enhance power output. Performance exhaust systems often have larger diameter pipes and more efficient mufflers, allowing for better flow and reduced backpressure. When choosing performance exhaust components, consider the material quality, design, and compatibility with your engine and desired sound preferences.

Considering Aftermarket Exhaust Systems

If you desire a complete upgrade to your vehicle’s exhaust system, considering aftermarket exhaust systems can bring significant benefits. Aftermarket exhaust systems are designed to optimize the performance and sound characteristics of your engine. They often include high-performance headers, catalytic converters, exhaust pipes, and mufflers that work seamlessly together to maximize power gain and reduce restrictions. Research reputable aftermarket exhaust system manufacturers and consult with experts to ensure proper fitment and compatibility with your vehicle.

Regularly Inspecting and Maintaining Exhaust System

Proper inspection and maintenance of the exhaust system are vital to ensure its longevity and optimum functionality. Periodically inspect the exhaust system for any signs of damage, corrosion, or leaks. Tighten any loose connections or clamps and replace any deteriorated gaskets or seals. Additionally, check for abnormal exhaust system noises, such as rattling or excessive vibration, which may indicate underlying issues. A well-maintained exhaust system contributes to improved engine performance and minimized potential exhaust-related problems.

Monitoring and Enhancing Engine Control

Using Engine Control Units or Programmable ECUs

Engine control units (ECUs) or programmable ECUs are electronic systems that govern the engine’s operation and performance. Upgrading to a more advanced ECU or utilizing programmable features of existing ECUs allows for more precise control over various engine parameters. These parameters include ignition timing, fuel delivery, boost control (if applicable), and other factors that directly impact performance. Selecting an ECU or programmable ECU that is compatible with your engine and offers the desired features can provide opportunities for significant performance enhancements.

Monitoring Engine Parameters with Gauges

Installing aftermarket gauges to monitor critical engine parameters provides valuable insights into the engine’s performance and health. Gauges such as oil pressure gauges, coolant temperature gauges, and boost gauges (if applicable) allow you to monitor these parameters in real-time while driving. Monitoring engine parameters helps detect any irregularities or abnormalities promptly, allowing for timely diagnosis and resolution of potential issues. A range of gauges is available to suit different needs and preferences, so research and select the most relevant gauges for monitoring your engine.

Considering Engine Tuning or Remapping

Engine tuning or remapping involves recalibrating the engine’s ECU to optimize performance, power delivery, and fuel economy. Tuning or remapping can involve adjustments to various engine parameters, such as ignition timing, fuel delivery, or turbo boost levels. This process is typically performed by professionals using specialized equipment or through user-friendly handheld devices. Engine tuning or remapping allows you to customize the engine’s characteristics based on your preferences and requirements, unlocking additional performance potential from your engine.

Utilizing Performance Chips or Modules

Performance chips or modules are plug-and-play devices designed to enhance the engine’s performance by modifying certain engine parameters. These devices connect to the ECU and provide pre-programmed or adjustable performance settings. Utilizing performance chips or modules can offer significant power gains without extensive modifications. They typically focus on optimizing ignition timing, fuel delivery, and sometimes turbo boost. If you are looking for a simple and effective performance enhancement, consider incorporating a performance chip or module into your engine customization.

Making Adjustments Based on Monitoring and Data

Monitoring various engine parameters and collecting data play a crucial role in making informed adjustments to optimize engine performance. Regularly review the collected data from gauges or diagnostic tools to identify areas for improvement. Analyze parameters such as engine speed, temperatures, boost levels, or air/fuel ratios to determine if any adjustments are necessary. Based on the collected data, make informed decisions regarding further customization, tuning, or adjustments to components such as fuel delivery, ignition timing, or boost levels.

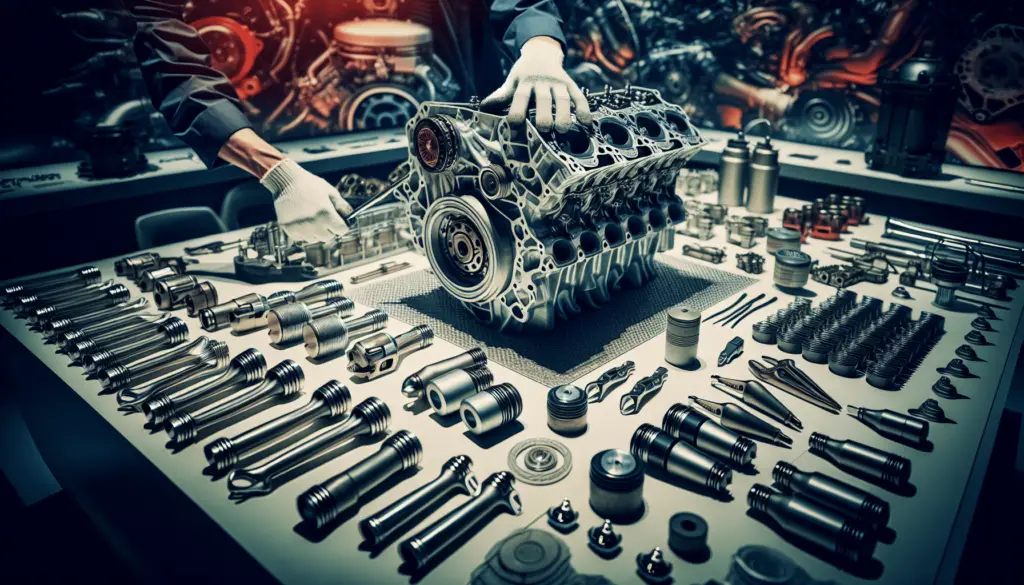

Strengthening Engine Block and Internals

Choosing Performance Engine Blocks

The engine block forms the foundation of the engine and provides the structural integrity required for its operation. When considering engine strengthening, selecting a performance engine block that can handle high horsepower and torque is crucial. Performance engine blocks often feature reinforced construction, thicker walls, and larger bore sizes. Upgrading to a performance engine block provides increased strength and durability, allowing for more aggressive power upgrades without compromising reliability.

Upgrading Connecting Rods and Pistons

Connecting rods and pistons are subjected to extreme forces during engine operation. Upgrading these components to aftermarket or performance versions can provide increased strength and durability. Performance connecting rods are made from high-strength materials and undergo specialized manufacturing processes for enhanced reliability. Upgraded pistons are designed to withstand higher compression ratios, increased cylinder pressures, and rigorous operating conditions. These upgraded components contribute to the overall strength and durability of the engine.

Using Forged or Billet Crankshafts

The crankshaft converts the reciprocating motion of the pistons into rotational motion. Upgrading to a forged or billet crankshaft can enhance engine strength and reliability. Forged crankshafts are made from high-strength steel and undergo a forging process that aligns the internal grain structure, increasing strength and resistance to fatigue. Billet crankshafts are machined from a solid piece of high-grade steel, providing exceptional strength and precision. These superior crankshaft options can handle higher horsepower and torque levels, contributing to a more robust engine.

Considering Engine Blueprinting

Engine blueprinting is a meticulous process that involves precisely matching and optimizing engine components to maximize performance and reliability. It includes careful measurements, balancing, honing, and meticulous assembly of engine internals. Blueprinting ensures that critical internal components, such as pistons, rods, and crankshafts, are perfectly matched, resulting in reduced friction, improved sealing, and enhanced overall performance. Consider consulting with experts or professional engine builders to perform blueprinting on your engine for superior performance and longevity.

Balancing and Blueprinting Internals

Internal engine components need to be balanced to minimize vibrations, reduce stress, and improve overall performance. Balancing often involves equalizing the weight distribution of rotating parts such as crankshafts, connecting rods, pistons, and flywheels. Balancing these components involves precise measuring, adjustments, and often the use of specialized equipment. Balancing and blueprinting internals ensure smoother engine operation, reduced stress on components, and improved long-term durability. Consider professional engine builders or machine shops with experience in balancing and blueprinting for optimal results.

Considering Forced Induction

Understanding Supercharging and Turbocharging

Forced induction refers to the process of compressing intake air to achieve higher power output. Two common methods of forced induction are supercharging and turbocharging. Superchargers are belt-driven devices that compress air using a pulley system, while turbochargers are driven by exhaust gases. Both methods provide a significant increase in air intake, resulting in more power and torque. Understanding the differences and advantages of supercharging and turbocharging can help you make an informed decision about which method is best suited for your engine and intended usage.

Choosing the Right Forced Induction System

When selecting a forced induction system, considerations such as engine size, power goals, and driving conditions come into play. Factors such as the desired power output, response characteristics, and packaging constraints influence the choice between supercharging and turbocharging. Research different forced induction systems and consult with experts or experienced professionals to determine the most suitable option for your engine. Proper selection and installation of a forced induction system can provide significant power gains while ensuring reliability and durability.

Upgrading Intercoolers for Better Cooling

Intercoolers play a vital role in cooling the compressed air from forced induction systems, enhancing engine efficiency and power delivery. Upgrading to larger, more efficient intercoolers can improve the cooling capabilities and overall performance of your forced induction system. Larger intercoolers offer increased surface area, allowing for better heat dissipation and cooler intake air temperatures. Cooler intake air results in denser air-fuel mixtures and improved combustion, leading to increased power output and reduced chances of detonation. Consider the available space and compatibility with your forced induction system when choosing an upgraded intercooler.

Ensuring Proper Boost Levels

Achieving and maintaining proper boost levels in forced induction engines is essential for optimal performance and longevity. Boost refers to the amount of compressed air being forced into the engine. Insufficient or excessive boost levels can lead to poor performance, increased strain on engine internals, and potential damage. Upgraded wastegates, blow-off valves, and boost controllers can help regulate and manage boost levels more effectively. Consult with experts or professionals who specialize in forced induction systems to ensure that your engine operates within safe and optimal boost levels.

Balancing Performance and Engine Longevity

When considering forced induction, it is important to strike a balance between performance gains and engine longevity. Increasing power output through forced induction places additional stress on engine components. It is crucial to select a forced induction system and associated components that are compatible with your engine’s strength and durability. Additionally, proper installation, tuning, and maintenance are essential to ensure the longevity of your engine. Regular monitoring, preventive maintenance, and addressing any issues promptly will help strike a balance between performance gains and engine reliability.

In conclusion, customizing your engine to increase longevity and durability requires thoughtful consideration, research, and careful component selection. Understanding the importance of engine parts, following regular maintenance schedules, enhancing engine cooling, optimizing fuel delivery, upgrading ignition systems, improving air intake, upgrading the exhaust system, monitoring and enhancing engine control, strengthening engine block and internals, and considering forced induction are key areas to focus on. By selecting the right engine parts, maintaining proper care, and incorporating suitable enhancements, you can enhance engine performance, longevity, and overall vehicle enjoyment.