If you’re a boat owner looking to improve your steering system, installing a hydraulic steering system could be a game-changer. Not only does it provide better control and responsiveness, but it also eliminates the need for manual steering effort. In this article, you’ll learn a step-by-step guide on how to install a hydraulic steering system on your boat. Whether you’re a seasoned boater or a beginner, this easy-to-follow process will have you enjoying smoother and more effortless steering in no time.

Choose the Right Hydraulic Steering System

When it comes to installing a hydraulic steering system on your boat, the first step is to choose the right one. There are a few factors to consider in order to make the best decision for your specific boat.

Consider your boat size and weight

The size and weight of your boat is an important consideration when choosing a hydraulic steering system. Larger and heavier boats will require a more robust system that can handle the additional load. On the other hand, smaller boats may not require as much hydraulic power. It’s important to consult the manufacturer’s specifications or seek professional advice to determine the appropriate system for your boat.

Choose between inboard and outboard steering

Next, you need to decide whether you want an inboard or outboard hydraulic steering system. Inboard systems are typically more common in larger boats with twin or multiple engines. They offer precise control and a smoother steering experience. Outboard systems, on the other hand, are more suitable for smaller boats with single engines. They are generally less expensive and easier to install.

Decide on the type of hydraulic steering system

Once you’ve determined the size and type of steering system you need, you can then choose between different types of hydraulic systems. There are two main types: balanced and unbalanced. Balanced hydraulic systems are designed to provide equal force in both directions, making steering effortless. Unbalanced systems, on the other hand, require additional effort when steering in one direction. The choice between the two largely depends on your personal preference and budget.

Gather the Necessary Tools and Materials

Before you can begin installing the hydraulic steering system, it’s important to gather all the necessary tools and materials. Having everything prepared ahead of time will make the installation process much smoother.

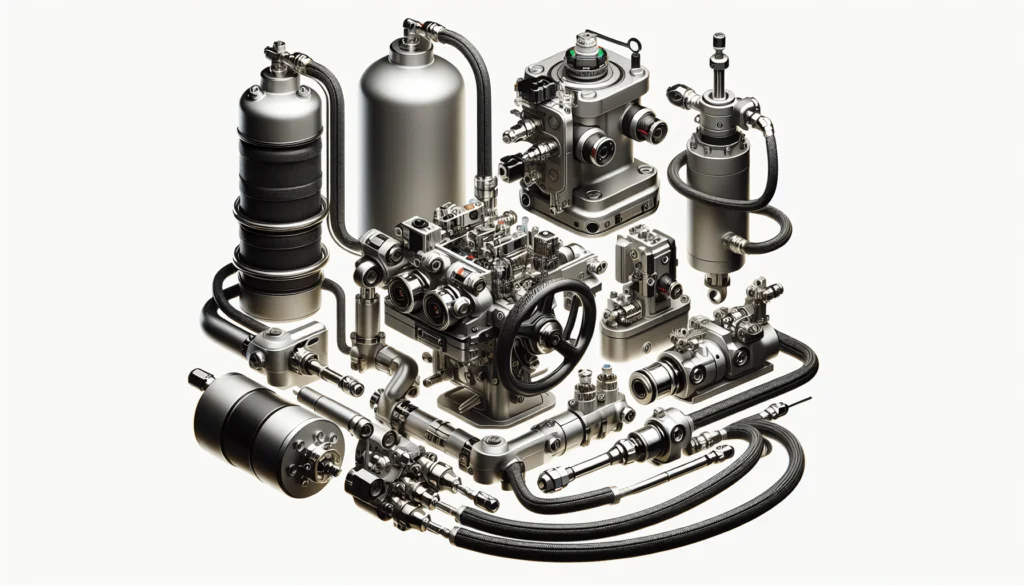

Hydraulic steering kit

The first item on your list should be a hydraulic steering kit. This will include the necessary components for the system, such as the helm assembly, hoses, fittings, and power steering pump. Make sure to choose a kit that is compatible with your boat’s specifications and the type of hydraulic system you’ve chosen.

Hoses and fittings

You’ll also need hydraulic hoses and fittings to connect the different components of the steering system. These hoses will transport the hydraulic fluid that powers the system. It’s important to choose hoses and fittings that are specifically designed for hydraulic steering applications to ensure proper functioning and prevent leaks.

Fluid reservoir

A fluid reservoir is another essential component of the hydraulic steering system. This reservoir holds the hydraulic fluid that powers the system. Make sure to choose a reservoir that is compatible with your chosen system and has the appropriate capacity for your boat.

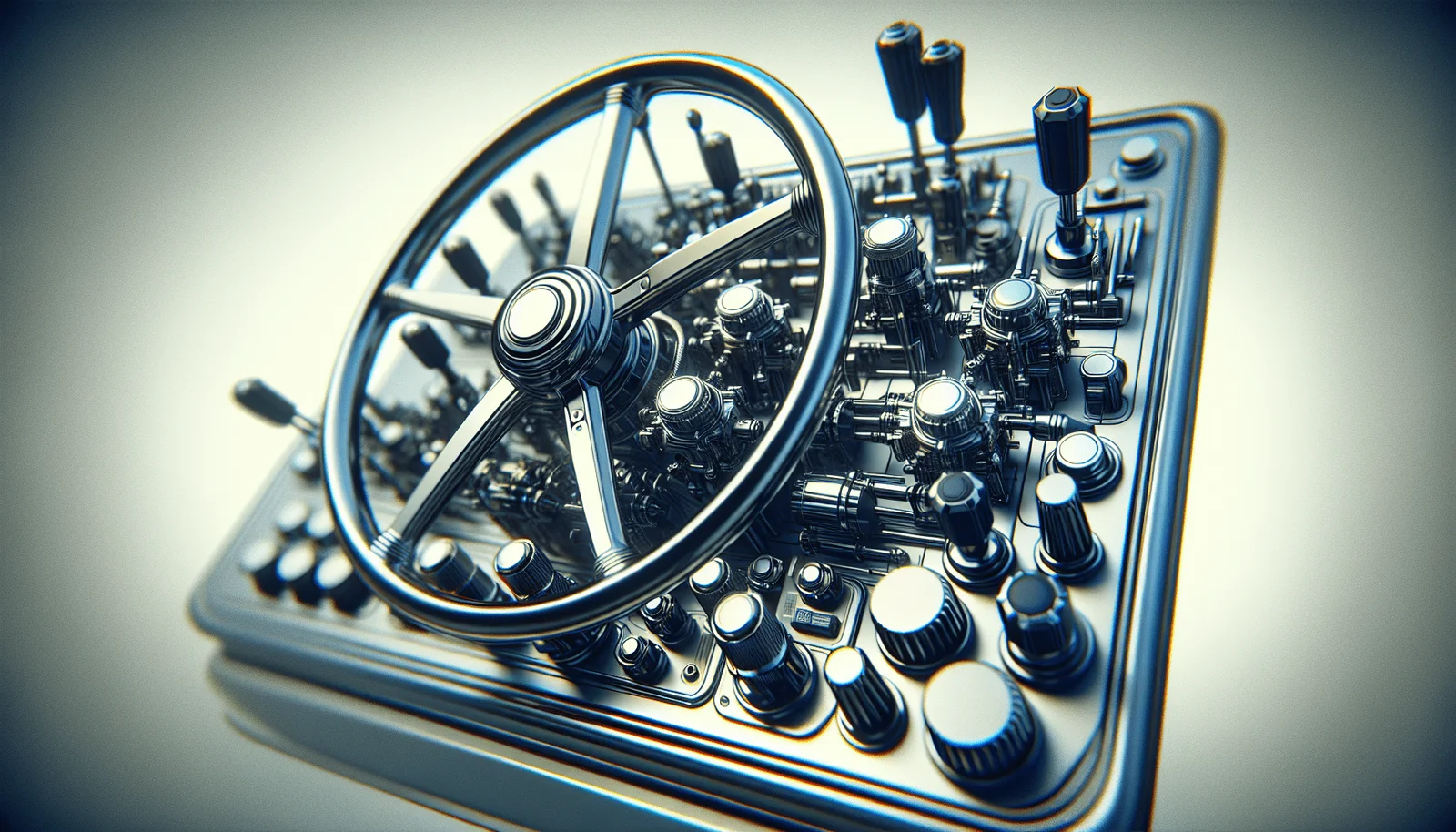

Steering wheel and helm assembly

The steering wheel and helm assembly are the parts of the system that you will interact with when steering your boat. Make sure to choose a steering wheel that is comfortable and easy to grip. The helm assembly is responsible for transmitting your steering input to the actual steering mechanism. Choose an assembly that is compatible with your chosen system and boat specifications.

Power steering pump

The power steering pump is what provides the hydraulic pressure to the system. Choose a pump that is compatible with your chosen system and boat specifications.

Mounting brackets and hardware

To secure the different components of the hydraulic steering system, you will need mounting brackets and hardware. Make sure to choose the appropriate brackets and hardware for the specific components and ensure that they are securely fastened to the boat.

Hydraulic fluid

Lastly, don’t forget to purchase the appropriate hydraulic fluid for your system. Different systems may have different fluid requirements, so consult the manufacturer’s instructions or seek professional advice to ensure you are using the correct fluid.

Miscellaneous tools such as wrenches, screwdrivers, and pliers

In addition to the specific components mentioned above, you will also need a variety of basic tools such as wrenches, screwdrivers, and pliers. These tools will be used throughout the installation process for tasks such as tightening fittings and securing hardware. Make sure to have a complete set of tools on hand before you start the installation.

Prepare Your Boat for Installation

Before you can begin installing the hydraulic steering system, it’s important to properly prepare your boat. This involves a few steps to ensure a smooth and successful installation process.

Turn off the boat’s engine

The first step is to turn off the boat’s engine. This is a safety precaution to prevent any accidents or injuries during the installation process. Make sure the engine is completely turned off and there is no risk of it starting up while you are working on the steering system.

Lock the boat’s steering wheel

To prevent any accidental movement of the boat’s steering wheel during the installation, it’s a good idea to lock it in place. This will ensure that the boat remains stable and stationary throughout the process. There are usually locking mechanisms available on the steering wheel, or you can use straps or clamps to secure it in place.

Find a suitable location for the hydraulic steering system

Next, you need to find a suitable location for the hydraulic steering system. This will depend on the layout and design of your boat, as well as the manufacturer’s recommendations. Look for an area that is easily accessible and provides enough space to mount the different components of the system.

Remove any existing steering system components

If your boat already has a steering system in place, you will need to remove it before installing the new hydraulic system. Follow the manufacturer’s instructions or seek professional advice to properly remove any existing steering system components.

Prepare the mounting location

Once the existing steering system components are removed, you can prepare the mounting location for the new hydraulic system. This may involve cleaning the area and making any necessary modifications or adjustments to accommodate the new components. Make sure the mounting location is secure and stable before proceeding with the installation.

Install the Helm Assembly

Now that your boat is properly prepared, you can begin the installation process. The first component to install is the helm assembly, which is responsible for transmitting your steering input to the actual steering mechanism.

Attach the helm assembly to the console

Start by attaching the helm assembly to the console of your boat. The console is usually located near the steering wheel and acts as the control center for various boat systems. Follow the manufacturer’s instructions or seek professional advice to properly attach the helm assembly to the console.

Connect the steering wheel to the helm assembly

Once the helm assembly is securely attached to the console, you can then connect the steering wheel to the helm assembly. This is typically done using a keyway and nut system. Follow the manufacturer’s instructions or seek professional advice to properly connect the steering wheel to the helm assembly.

Secure all connections with appropriate hardware

To ensure the helm assembly is securely attached and there is no risk of it coming loose during operation, make sure to use the appropriate hardware to secure all connections. This may include nuts, bolts, or screws. Tighten the hardware securely but be careful not to overtighten and risk damaging the components.

Mount the Power Steering Pump

The power steering pump is responsible for providing the hydraulic pressure to the system. Proper installation of the pump is crucial for the overall functioning of the hydraulic steering system.

Find a suitable location for the power steering pump

Start by finding a suitable location for the power steering pump. This will largely depend on the layout and design of your boat, as well as the manufacturer’s recommendations. Look for an area that is easily accessible and provides enough space to mount the pump.

Secure the mounting brackets and hardware

Once you’ve found the suitable location, secure the mounting brackets and hardware. Make sure to use the appropriate hardware provided with the pump to ensure a secure and stable installation.

Attach the pump to the mounting brackets

Once the mounting brackets are securely in place, you can then attach the power steering pump to the brackets. Follow the manufacturer’s instructions or seek professional advice to properly attach the pump. Make sure the pump is securely mounted and there is no risk of it coming loose during operation.

Connect the Hoses

The next step in the installation process is to connect the hydraulic hoses. These hoses will transport the hydraulic fluid throughout the system, providing the necessary power for steering.

Measure and cut the hydraulic hoses to the appropriate length

Start by measuring and cutting the hydraulic hoses to the appropriate length. It’s important to ensure that the hoses are not too long or too short, as this can affect the overall functioning of the system. Follow the manufacturer’s instructions or seek professional advice to properly measure and cut the hoses.

Attach the hoses to the helm assembly and power steering pump

Once the hoses are cut to the appropriate length, you can then attach them to the helm assembly and power steering pump. Make sure to use the appropriate fittings provided with the system to ensure a secure and leak-free connection. Follow the manufacturer’s instructions or seek professional advice to properly attach the hoses.

Secure the hoses with fittings

To prevent any leaks or disconnects, it’s important to secure the hoses with fittings. These fittings will ensure that the hoses are properly attached and won’t come loose during operation. Follow the manufacturer’s instructions or seek professional advice to properly secure the hoses with fittings.

Ensure tight connections to prevent leaks

Finally, before moving on to the next step, make sure to double-check all connections and fittings to ensure they are tight and secure. This will help prevent any leaks and ensure the proper functioning of the hydraulic steering system.

Install the Fluid Reservoir

The fluid reservoir holds the hydraulic fluid that powers the steering system. Proper installation of the reservoir is important to ensure a reliable and efficient hydraulic steering system.

Choose a suitable location for the fluid reservoir

Start by choosing a suitable location for the fluid reservoir. This will depend on the layout and design of your boat, as well as the manufacturer’s recommendations. Look for an area that is easily accessible and provides enough space to mount the reservoir.

Secure the reservoir using mounting brackets and hardware

Once you’ve found the suitable location, secure the reservoir using the provided mounting brackets and hardware. Make sure to use the appropriate hardware to ensure a secure and stable installation.

Connect the reservoir to the rest of the hydraulic system with hoses

To complete the installation of the fluid reservoir, you need to connect it to the rest of the hydraulic system with hoses. Make sure to use the appropriate fittings provided with the system to ensure a secure and leak-free connection. Follow the manufacturer’s instructions or seek professional advice to properly connect the reservoir to the hydraulic system.

Bleed the System

Bleeding the hydraulic steering system is an essential step to ensure proper functioning and prevent any air bubbles that may compromise the steering performance.

Follow the manufacturer’s instructions to bleed the hydraulic system

Start by referring to the manufacturer’s instructions or seek professional advice on how to properly bleed the hydraulic system. Different systems may have different bleeding procedures, so it’s important to follow the specific instructions for your system.

Remove any air bubbles from the system to ensure proper functioning

The goal of bleeding the system is to remove any air bubbles that may be trapped inside. This will ensure that the hydraulic fluid flows smoothly and there are no air pockets that could affect the steering performance. Follow the manufacturer’s instructions or seek professional advice on how to properly remove any air bubbles.

Test the Steering System

Once the hydraulic steering system is installed and properly bled, it’s time to test its functionality and ensure that everything is working properly.

Start the boat’s engine

Start by starting the boat’s engine. This will power the hydraulic system and allow you to test the steering functionality.

Turn the steering wheel in both directions

With the engine running, turn the steering wheel in both directions to test the responsiveness and smoothness of the steering. The steering should be easy to turn and there should be no resistance or unexpected movements.

Check for smooth and responsive steering

As you turn the steering wheel, pay attention to how the boat responds. The steering should be smooth and responsive, allowing you to maneuver the boat with ease. If you notice any issues or abnormalities, consult the manufacturer’s instructions or seek professional advice to troubleshoot and resolve the problem.

Troubleshooting and Maintenance

Once the hydraulic steering system is installed and tested, it’s important to regularly monitor and maintain its condition to ensure longevity and optimal performance.

Identify and fix any issues with the hydraulic steering system

Regularly inspect the hydraulic steering system for any signs of wear, damage, or malfunction. If you notice any issues, such as leaks, abnormal noises, or difficulty in steering, it’s important to identify and fix these issues promptly. Consult the manufacturer’s instructions or seek professional advice to properly diagnose and resolve any problems with the system.

Regularly check and maintain the system’s fluid level and condition

Check the hydraulic fluid level regularly and top it up as needed. Additionally, inspect the fluid condition to ensure it is clean and free from contaminants. If the fluid appears dirty or contaminated, it’s important to replace it according to the manufacturer’s recommendations.

Inspect hoses, fittings, and connections for any signs of wear or damage

Inspect the hoses, fittings, and connections of the hydraulic steering system for any signs of wear, damage, or loose connections. Tighten any loose fittings and replace any worn or damaged components as needed. Regular inspections will help prevent any potential issues and ensure the long-term functionality of the system.

By following these steps and properly installing a hydraulic steering system on your boat, you can enjoy a smooth and responsive steering experience on the water. Remember to always consult the manufacturer’s instructions or seek professional advice when in doubt, and regularly maintain and inspect the system to prolong its lifespan. Happy boating!