Struggling with a deteriorating boat engine after a stint of non-use is undoubtedly one of the worst headaches for a sailor. In “How To Properly Store And Preserve Your Boat Engine During Long Periods Of Inactivity,” you will find an engaging walk-through on this very topic. It provides you with a reliable blueprint to ensure your boat’s engine remains pristine and ready for action, even after prolonged dormancy. You will explore practical steps ranging from draining the coolant to changing the oil, covering all aspects of engine maintenance and preservation.

Understanding the Importance of Proper Storage

Storing your boat engine properly is an essential part of boat maintenance that often goes overlooked. This is even more crucial during periods of inactivity. Whether you live in a place with harsh winters or are just not aboard as frequently, your boat engine needs to be cared for to ensure its longevity.

Why engine care is crucial during inactivity

Inactivity can be just as damaging to a boat engine as overuse. When boat engines are idle for extended periods, they become vulnerable to corrosion, fuel degradation and component breakdown. Water can intrude, oil can separate and several other issues can occur that could drastically affect the engine’s performance when you next use your boat.

The negative effects of improper storage

Leaving an engine unattended can lead to a buildup of rust and corrosion due to trapped moisture, especially in humid climates. As for the fuel system, gasoline can break down over time and form a sticky residue (or varnish) that clogs the fuel system. If unchecked, cooling system issues could turn your engine into a rust-filled, clogged mess.

Potential costs of neglecting boat engine maintenance

Neglecting your engine’s need for care during periods of inactivity can lead to significant repair costs. If damage occurs, you may be looking at the cost of replacing fuel lines, carburetors, pumps, engine components, or even the entire engine. Also, a boat with a well-maintained engine retains more value, making it a solid financial investment to provide care even in downtime.

Assessing Your Boat Engine’s Condition

Before you proceed with any maintenance tasks, it’s crucial to assess the overall health of your engine. The goal here is to identify any issues that need addressing before you place your boat in storage.

Assessing external engine condition

Begin by cleaning the external part of your boat engine. Look out for signs of damage, leaks, or corrosion. Any discoloration on the oil filter, hoses, and belts might signify oil leaks, overheating or wear.

Checking internal engine components

With the external inspection done, move on to the inside. Ensure the cooling system is functioning well without any leakages. Check the gear oil for any signs of milky emulsion, which indicates water intrusion in the lower unit. Scan for any plugs or wires that might need replacing as well.

Identifying necessary repairs prior to storage

This comprehensive assessment lets you pinpoint the repairs needed ahead of storage. Delegate these repairs to a professional or tackle them yourself if you’re confident in your abilities. Your boat will appreciate the care!

Preparing your Engine for Storage

Clean and protecting your engine to prepare it for storage is essential in preventing damage incurred over long periods of inactivity.

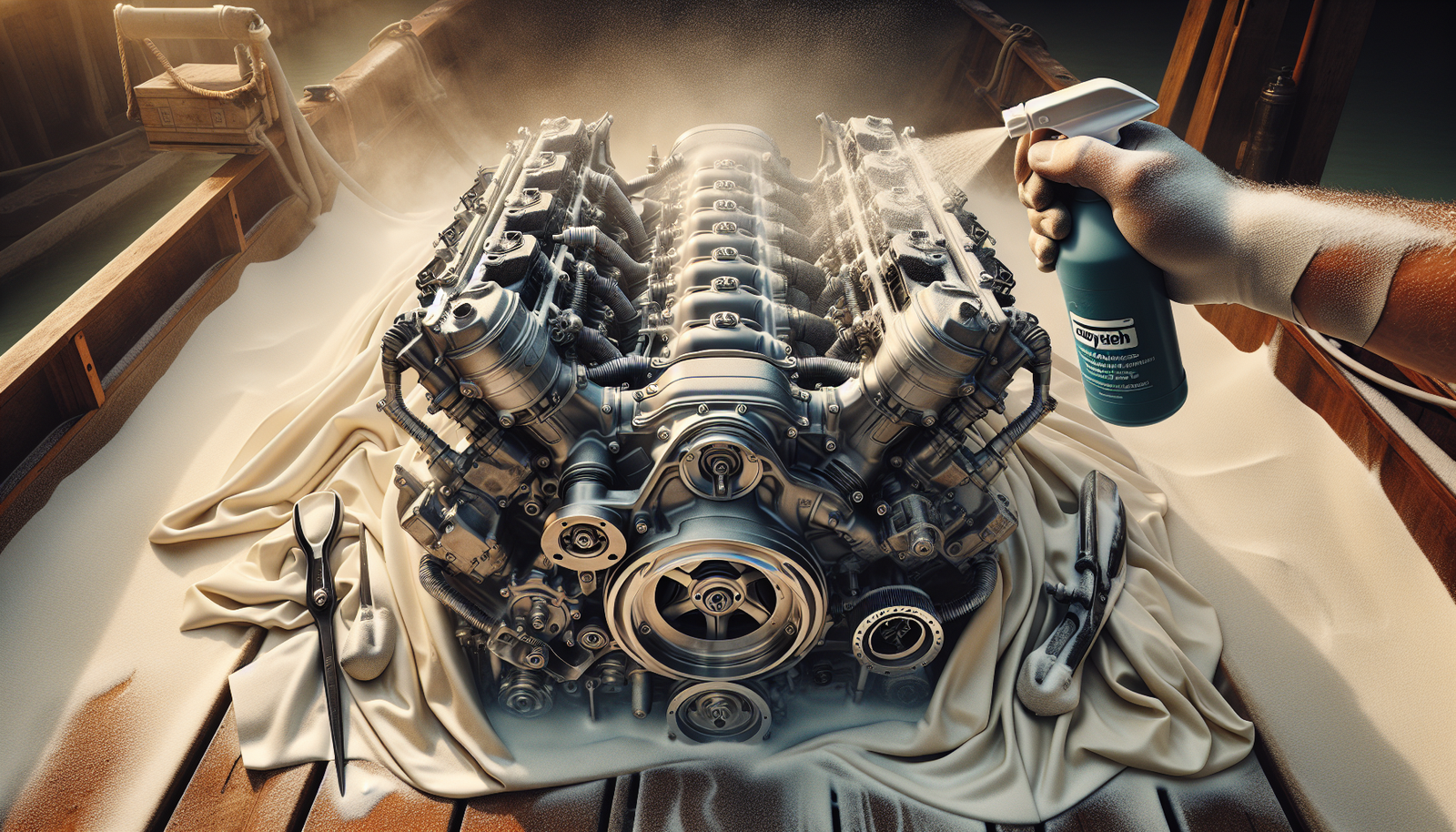

Proper cleaning techniques

Cleaning your boat engine involves a thorough wash down. Use clean, fresh water and a mild detergent to gently scrub all external surfaces. A soft bristle brush will help reach into crevices.

The importance of drying your engine

Once the boat engine is clean, the next step is to properly dry it. This is because any residual moisture left upon storage could cause rust and corrosion. Use compressed air or a cloth to dry out each component.

Applying anti-rust and anti-corrosion treatments

After drying, use a protective, anti-corrosion spray to coat exposed metal components, paying attention to the cylinder walls and piston heads. This step ensures the engine remains in good shape during storage.

Using Fuel Stabilizers

Fuel degradation and the resulting damage can be mitigated by using fuel stabilizers.

Purpose of fuel stabilizers

Fuel stabilizers work by preventing ethanol separation, protecting against corrosion and dissolving gum and varnish in the fuel system. They enhance the storage life of the fuel, ensuring that your boat engine starts up smoothly after an extended storage period.

Choosing the right fuel stabilizer

When selecting a fuel stabilizer, look for ones specifically designed for boat engines or those versatile to handle all gasoline engines. Also, check the product’s recommended usage, as too much or too little could harm your engine.

How to use a fuel stabilizer effectively

Using a fuel stabilizer is quite straightforward. You need to add the recommended amount to the fuel tank, then run the engine for a few minutes to circulate the stabilizer throughout the fuel system.

Draining the Engine

Before storage, it’s imperative to drain your boat engine of all fluids. This prevents possible damage from condensation that can build-up over time.

Why you should drain your engine before storage

Draining the engine clears it of any water or moisture that could freeze (in colder climates) or become a breeding ground for bacteria and fungi, which can corrode your engine.

Step-by-step guide to draining your boat engine

To drain your engine, start by running it to warm up the oil, then open the drain valve and allow the oil to flow into an appropriate container. Close the drain plug and refill with new oil, stopping a little short of the full mark. Run the engine again to circulate the new oil.

Safety considerations when draining your engine

Always be careful when handling oil, as it can be hazardous. Use a closed container for collecting the oil and dispose of it properly. Avoid contact with skin and keep your workspace well-ventilated to minimize the risk of fumes.

Oil Changes and Lubrication

Your boat engine’s oil is its lifeblood, and as such, it needs to be changed regularly.

Why oil changes are necessary

Oil breaks down and gathers impurities during use. So, changing your oil right before storage ensures that your engine is lubricated by fresh, clean oil, thereby minimizing the chances of damage.

How to change your engine’s oil

To change your engine’s oil, first warm up the engine, then use an oil pump to extract the old oil. Refill with new oil of appropriate viscosity. Always replace the oil filter when you change the oil.

Properly lubricating engine components for storage

Apart from the engine oil, you also need to take care of other moving parts. Apply a coat of lubricant to the power head and the propeller shaft, making sure all surfaces are covered. Also, engage the water pump’s impellers to ensure they stay pliable in storage.

Preparing the Cooling System

Your boat engine’s cooling system also needs some attention before storage.

Why it’s important to prepare your cooling system for storage

Any water left in the cooling system can freeze in cold weather, causing significant damage. Even in warmer climates, trapped moisture can cause corrosion and mineral buildup.

How to flush the cooling system

To flush your cooling system, you’ll need clean, fresh water and a motor flusher that fits your boat’s motor. Run the engine with the flusher in place to push out any accumulated debris or water. Follow your engine manufacturer’s instructions regarding the use of flushing agents.

Adding antifreeze to the cooling system

Once you’ve flushed the cooling system, the next step is to add antifreeze. The process involves feeding the antifreeze into the intake hose until it flows out of the water pump. Remember to choose marine-grade, non-toxic antifreeze that’s safe for the environment.

Safeguarding Electrical Systems

Much like the engine itself, the boat’s electrical systems need to be protected during storage.

Preventing damage to electrical systems

Start by disconnecting all electronic devices. Clean and dry all connections, then apply a small amount of silicon-based protectant to prevent corrosion. Remove any batteries and store them in a cool, dry place.

Disconnecting and storing batteries

It’s best to remove the battery altogether. Place it on a clean, dry surface in a well-ventilated area. Use a trickle charger to maintain battery health throughout the period of storage.

Protecting the alternator during storage

To protect your alternator, check that all connections are clean and secure. Apply a protective spray to the alternator and other electrical connections to prevent rust and corrosion.

Choosing a Storage Location

A good storage location plays a crucial part in maintaining your boat engine during inactivity.

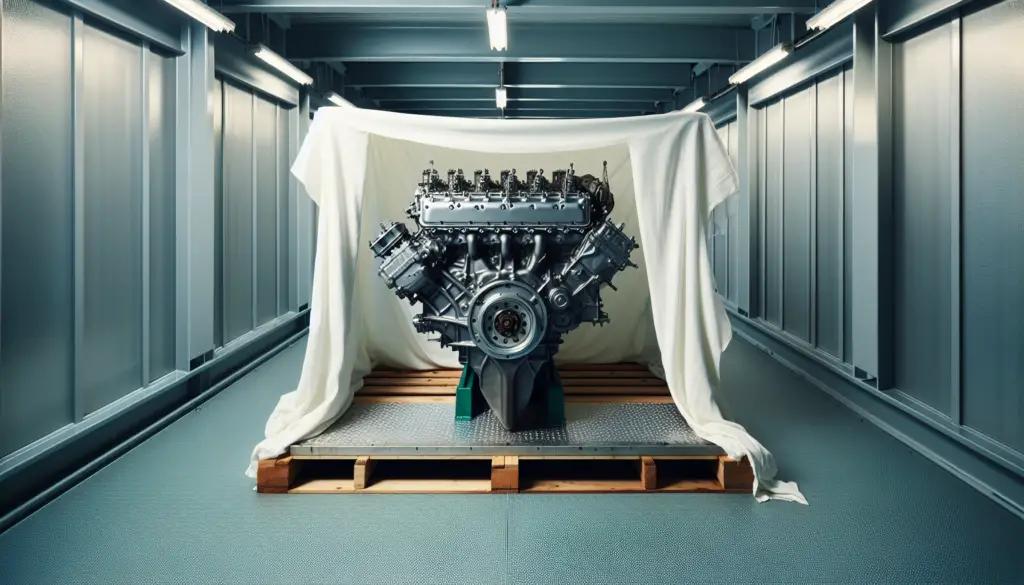

Factors to consider in a storage location

Your storage location should be dry, clean, and well-ventilated. Ideally, the temperature in this space should remain constant– too much fluctuation can harm the engine. Choose a secure location to prevent any theft or vandalism.

Indoor versus outdoor storage

If possible, go for indoor storage as it provides better protection against changing weather conditions. However, if you opt for outdoor storage, make sure you use a high-quality, waterproof and breathable cover for your boat.

Preparing the storage area

Sweep the storage area clean and ensure there’s enough space for you to move around your boat. If possible, place wooden blocks under the trailer wheels to keep tires off the ground, which prevents flat spots.

Ongoing Maintenance during Storage

Even after storing, your boat engine requires regular check-ups.

How often to check on your stored engine

Try to check on your engine every couple of months or so. This can go a long way in preventive maintenance and catching any potential issues.

What to look for during storage check-ups

During your check-ups, inspect the engine for any signs of rust or corrosion. Look out for any rats or insects that may have taken residence. Also, check the batteries if they are kept on chargers.

Reacting to signs of wear or damage

If you discover any problems during your inspections, arrange for repairs immediately. Don’t wait until you’re ready to use the boat – the issue could become worse, leading to more significant damage and costly repairs.

In conclusion, properly storing and preserving your boat engine during long periods of inactivity is an essential practice all boat owners should implement. It may require some time and effort, but it’s definitely worth it to ensure your boat engine runs reliably and efficiently when you’re ready to use it.