Picture this: after a great summer of sailing, you decide to dock your boating gear for a fall break, not planning to use it again until the next summer. In such cases, utmost care should be taken to ensure that your boat engine is prepared for the long hiatus. Your boat engine is a valuable asset that requires preventative maintenance to avoid costly repairs in the future. In “How to Properly Store and Preserve Your Boat Engine During Long Periods.”, you’ll discover essential steps to safeguard your boat engine, helping it endure the seasonal downtime without losing its spark.

Understanding the Importance of Proper Engine Storage

Proper storage of your boat engine is crucial, especially during periods of long-term inactivity. If you’re thinking, “I’ll deal with it when it’s time to use the boat”, you might want to rethink that approach. Storing your engine correctly can help prolong its lifespan and prevent serious damage.

Effects of long-term inactivity on boat engines

When engines sit idle for extended periods, harmful side effects begin to manifest. The seals can dry out, leading to potential leaks. Your engine’s internal components are susceptible to corrosion, and stale fuel could clog the fuel system. Ignoring these risks can lead to pricey repairs and costly downtime.

Importance of regular maintenance and storage

Regular maintenance and proper storage are much like eating healthy and exercising—it does a body (or in this case, engine) good! By adhering to a thorough maintenance routine and secure storage practice, you’ll increase the longevity of your engine. Plus, you’ll avoid the heartache of a ruined outing due to engine failure.

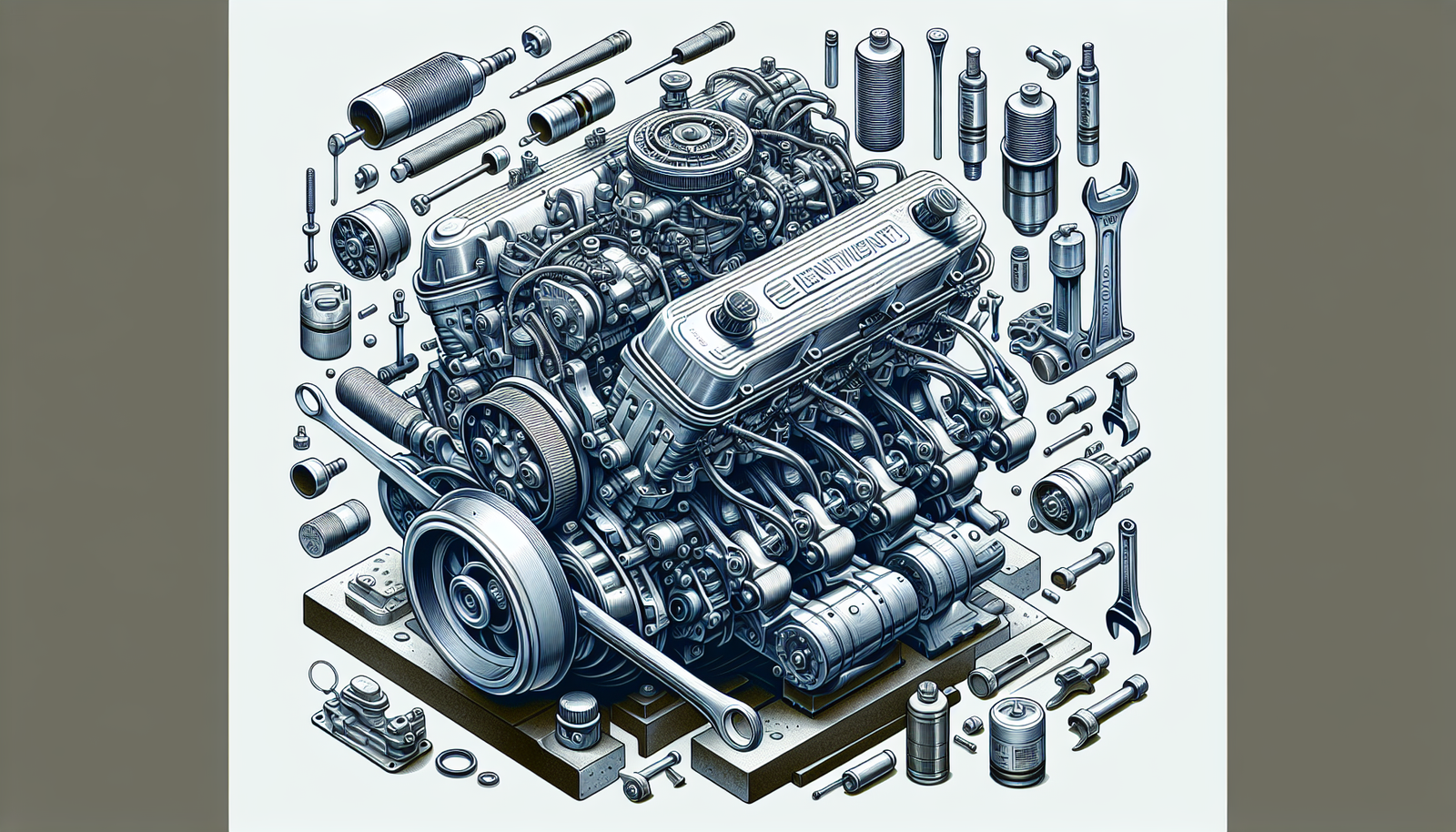

Prior to Storage Engine Inspection

Before your beloved boat engine goes into hibernation, it’s essential that a comprehensive inspection is carried out.

Checking for engine damages

Start by examining your engine for any signs of damage. Look for cracks, rust, wear, and other telltale signs of trouble. You don’t want to discover any nasty surprises when you’re eager to get back on the water.

Ensuring all components are functioning correctly

Next, ensure all components are working correctly. Check your spark plugs, cooling system, engine controls, fuel system, and other important parts. This is like giving your engine a full health exam before it goes to sleep for a while.

Assessing the engine oil and filter status

Finally, assess the condition of your engine oil and filter. Old, dirty oil can leave harmful deposits in your engine, and a clogged filter won’t protect your engine adequately. Replacing these components is a vital step in the storage process.

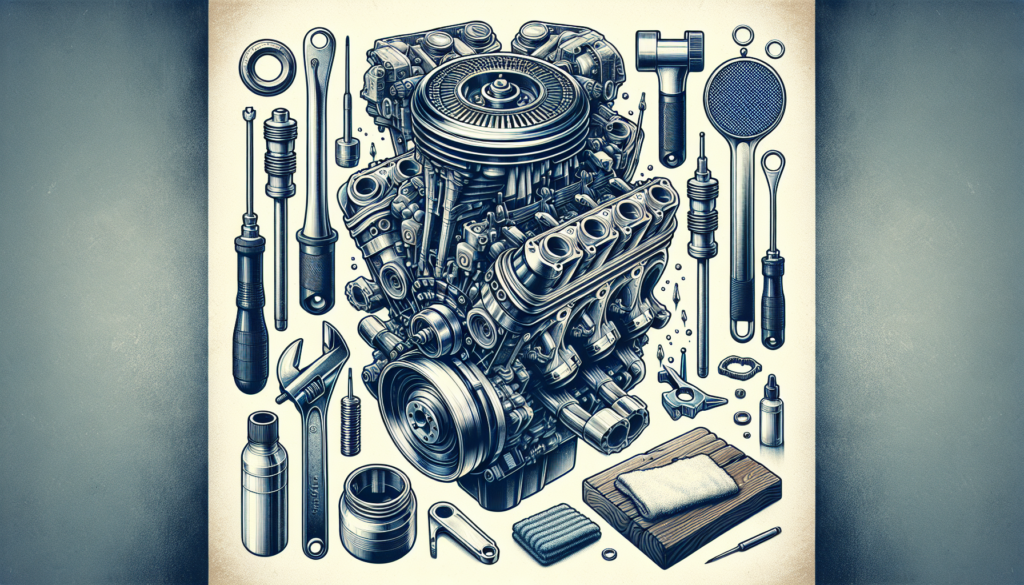

Performing a Thorough Engine Cleaning

Giving your engine a good scrubbing before storage is not just about making it look good. It can reveal hidden problems and preserve the health of your engine.

Cleaning methods for boat engine

Use a gentle but effective cleaning method to safely remove dirt and grime from your engine. A small brush or cloth, combined with a targeted engine cleaner, should do the trick.

Materials and solutions best for engine cleaning

When choosing cleaning solutions, opt for ones specifically made for boat engines. Avoid harsh chemicals which could harm your engine’s delicate components. A rag and a can of compressed air can also be handy for wiping and blowing away stubborn dirt.

The Importance of a clean engine before storage

A clean engine before storage prevents the build-up and hardening of grime, which can cause damage in the long run. It also allows you to better inspect the engine for any issues.

The Significance of Fuel System Preparation

Proper fuel preparation can prevent a whole host of issues down the line.

Understanding fuel degradation

Over time, fuel degrades. This leads to the creation of a sticky residue known as varnish. Varnish can clog fuel lines and carburetors, making your engine run poorly and decreasing its lifespan.

How to treat and stabilize the fuel system

To protect against fuel degradation, it’s necessary to add a fuel stabilizer. Adding a stabilizer keeps the fuel fresh and prevents varnish. Run your engine for a few minutes after adding the stabilizer to ensure it reaches every part of your fuel system.

Draining vs. filling the fuel tank before storage

There’s a bit of a debate over whether it’s better to drain or fill your fuel tank before storing your engine. For the best of both worlds, fill your tank to about 95 percent. This keeps your fuel system moist to prevent seals from drying but leaves a little room to accommodate any fuel expansion.

Engine Oil and Filter Change

Changing your engine oil and filter should be part of your storage routine.

The importance of changing engine oil and filter

Old oil contains contaminants that could corrode your engine’s internal parts over time. A new filter ensures your freshly replaced oil is properly filtered, protecting your engine.

Choosing the right oil and filter

Choosing the right oil and filter is crucial. Follow your manufacturer’s recommendations and consult your owner’s manual for the best options.

Steps in changing engine oil and filter

Changing engine oil and filter involves draining the old oil, replacing the filter, and filling your engine with new oil. Do this while your engine is slightly warm; warm oil drains faster and more thoroughly.

Fogging the Engine

Fogging provides your engine an extra layer of protection against rust and corrosion.

What is engine fogging and why it is necessary

Fogging involves spraying a special oil into your engine’s cylinders and carburetor. This oil clings to internal parts to protect them from rust and corrosion.

How to fog your boat engine

To fog your engine, spray the fogging oil into the air intake while your engine is running. You want to use enough oil to stall the engine—this ensures your internal parts are thoroughly coated.

Choosing the best fogging oil for your engine

Check your manufacturer’s recommendations or owner’s manual for the best fogging oil for your engine. If you’re unsure, there are universal fogging oils which work for most engines.

Protecting the Cooling System

Your cooling system plays a crucial role in maintaining your engine’s temperature—don’t neglect it!

Properly draining the cooling system

Before storage, make sure to properly drain the cooling system. This removes any water which, if frozen, could damage your engine.

Appropriate antifreeze selection and usage

After draining, fill the system with antifreeze. This helps to prevent rust and corrosion, as well as freeze damage. Use an antifreeze tester to ensure you achieve the right mix of antifreeze and water.

Ensuring a corrosion-free cooling system during inactivity

To maintain a corrosion-free cooling system during inactivity, follow your manufacturer’s instructions for flushing and filling your cooling system. This might seem like a hassle, but your engine will thank you!

Battery Maintenance and Storage

Before storing your engine, don’t forget to tend to your battery.

Checking the battery’s condition

Perform a thorough inspection of your battery. Check the charge and examine it for any signs of damage like cracks or corrosion.

Proper battery storage methods

Storing your battery correctly helps maintain its charge during inactivity. Disconnect it, give it a clean, and store it in a cool, dry place.

Preserving battery life during inactivity

While the battery is stored, it’s a good idea to periodically recharge it. This prevents it from completely discharging and extends its life.

Final Steps: Engine Sealing and Covering

Your engine is now almost ready for its extended break!

Securing all engine parts

Ensure all parts are secure. Loose or improperly secured parts could become damaged during storage.

Benefits of sealing and covering the engine

Sealing and covering your engine helps protect it from dust, moisture, and pests. This extra layer of protection will keep your engine clean and ready for its next use.

Choosing the right engine cover for storage

When choosing an engine cover, consider factors like the material, durability, and fit. A good cover should be breathable, to prevent moisture build-up, but also sturdy enough to defend against dust and pests.

Preparing For Engine Reactivation

When the time comes to revive your engine, approach it with care.

Unsealing and uncovering the engine

Start with removing the engine cover and any seals you might have placed. Check for any signs of damage or pest infestation.

Proper startup sequence for a long inactive engine

Reviving an idle engine requires running it on low speed for the initial few minutes, checking the engine oil, and then gradually building up speed. This allows the oil to circulate through the engine and prevent any damage due to dry start.

Potential issues upon reactivation and how to handle them

Finally, be prepared for potential issues when you reactivate your engine. Remember, your engine isn’t used to the action after all this time. There might be some minor hiccups, but with patience and your owner’s manual, you’ll have your engine humming happily in no time!