Imagine this: you’re planning to put your boat into storage for the off-season, or simply won’t be using it for an extended period. One of the most important steps you should take, often overlooked, is to properly store and preserve your boat engine. This ensures that when the time comes for you to sail again, your engine is ready and raring to go, free from undue wear and tear. This article guides you through the necessary steps and precautions to correctly store and preserve your boat engine during extended inactivity.

Understanding Why Proper Storage Is Essential

Do you remember the last time you used your boat? If it’s been a while, chances are, the idle boat engine might not be in its tip-top shape. Boat engines are designed to be active, blasting through the waves. Therefore, long periods of inactivity can lead to issues.

The Impact of Inactivity on Boat Engines

You see, the parts inside the engine are continuously lubricated by the movement of the boat and the engine. This constant movement keeps all the internal components in shape. However, when idle for too long, the lubricant can settle, initiating rust and corrosion on the interior parts thus affecting overall performance.

Risks of Improper Storage to Engine Lifespan

There’s more to it as well. Improper storage of your boat engine could harm the lifespan of the engine. It would be vulnerable to the risk of damaged seals, corrosion, clogged carburettors and fuel systems, dried out impellers, and so on. These minor issues can escalate quickly if left unattended, affecting your boat engine’s lifespan.

Choosing the Right Environment for Storage

Alright, we’ve made our point about why storage is essential. Now, let’s understand the right way to store your boat engine.

Ideal Conditions for Boat Engine Storage

The best environment for storing your boat engine is a covered, dry area with controlled humidity. Avoid places with drastic temperature changes to prevent condensation inside the engine.

Factors to Consider When Selecting Storage Space

In addition to finding the perfect conditions, be mindful of the safety aspects. Ensure your storage spot has no leaking roofs or accumulation of flammable substances like gasoline or cleaning solvents. Don’t forget to consider good ventilation too, as it can help maintain an ideal environment inside the storage shed.

Draining Fuel System and Carburator

Arguably the most critical step in the storage process is draining fuel.

How to Safely Drain and Clean the Fuel System

Before starting, ensure a safe working environment. Ideally, you must drain the fuel at an approved waste recycling center to avoid accidental ignition or environmental pollution. You can drain the residual fuel using a suitable hand pump.

Removing Fuel from the Carburator

While draining the fuel tank, do not forget the carburetor, which has tiny holes that can get clogged if residue fuel solidifies over a period of being idle.

Fuel Stabilizer and Its Uses

Fuel stabilizers come into play when you plan on storing your boat with fuel. They prevent the fuel from breaking down and forming a varnish-like gunk that can clog your fuel system. It’s a pretty handy tool, isn’t it?

Removing and Recharging Battery

There’s also the battery to consider when planning long-term storage.

Proper Disconnection and Removal of Boat Engine’s Battery

Before removing the battery from your boat, you should disconnect the negative terminal first to prevent short-circuits. Headwear and gloves are good ideas to protect you from accidental acid spillages.

Recharging and Storing the Battery

After removal, you should charge the battery fully and store it in a cool, dry place away from flammable substances. Lay a wooden board on a concrete floor and place the battery on it. This act helps in preventing slow discharge.

Treatment of Cooling System

What’s next? Yes, the cooling system. Let’s dive into that.

Flushing the Cooling System

Give your cooling system a good flush-out with fresh water before storage. This action would remove any salt, sand, or corrosion that might have accumulated.

Risks of Leaving Water in the Cooling System

Watch out for any leftover water in your cooling system. If it freezes, it can cause severe damage. Frozen water could crack the engine block, pump housing, and other essential components.

Applying Antifreeze

To avoid any potential damage, use marine safe antifreeze products. They can protect your engine from freezing and also prevent rust and corrosion.

Lubricating the Engine

Yes, lubricating the engine before storage is crucial. Curious why? Read on.

Why Lubrication Is Necessary for Storage

During storage, the engine isn’t active, and lubricant does not circulate. However, proper lubrication before storage ensures engine parts do not rust or seize due to inactivity.

Types of Lubricants to Use

Ensure that you use a quality lubricant suitable for marine engines to help maintain their pristine state.

How to Properly Lubricate the Engine

Begin with a warm engine, and remember to replace the oil filter as well. After you’ve done that, apply fogging oil to the carburetor while the engine is running and until it stalls.

Cleaning and Protecting the Engine’s Exterior

An idle boat engine also needs external protection.

Cleaning off Salt and Other Deposits

Before storage, wash off the engine meticulously to remove any salt, mud, or other deposits. Saltwater can be corrosive to metal parts, thus cleaning them off is a must.

Applying Anti-Corrosion Spray

After you clean and dry the engine, don’t postpone applying an anti-corrosion spray. It would form a protective layer against moisture, which is useful in keeping rust and damage at bay.

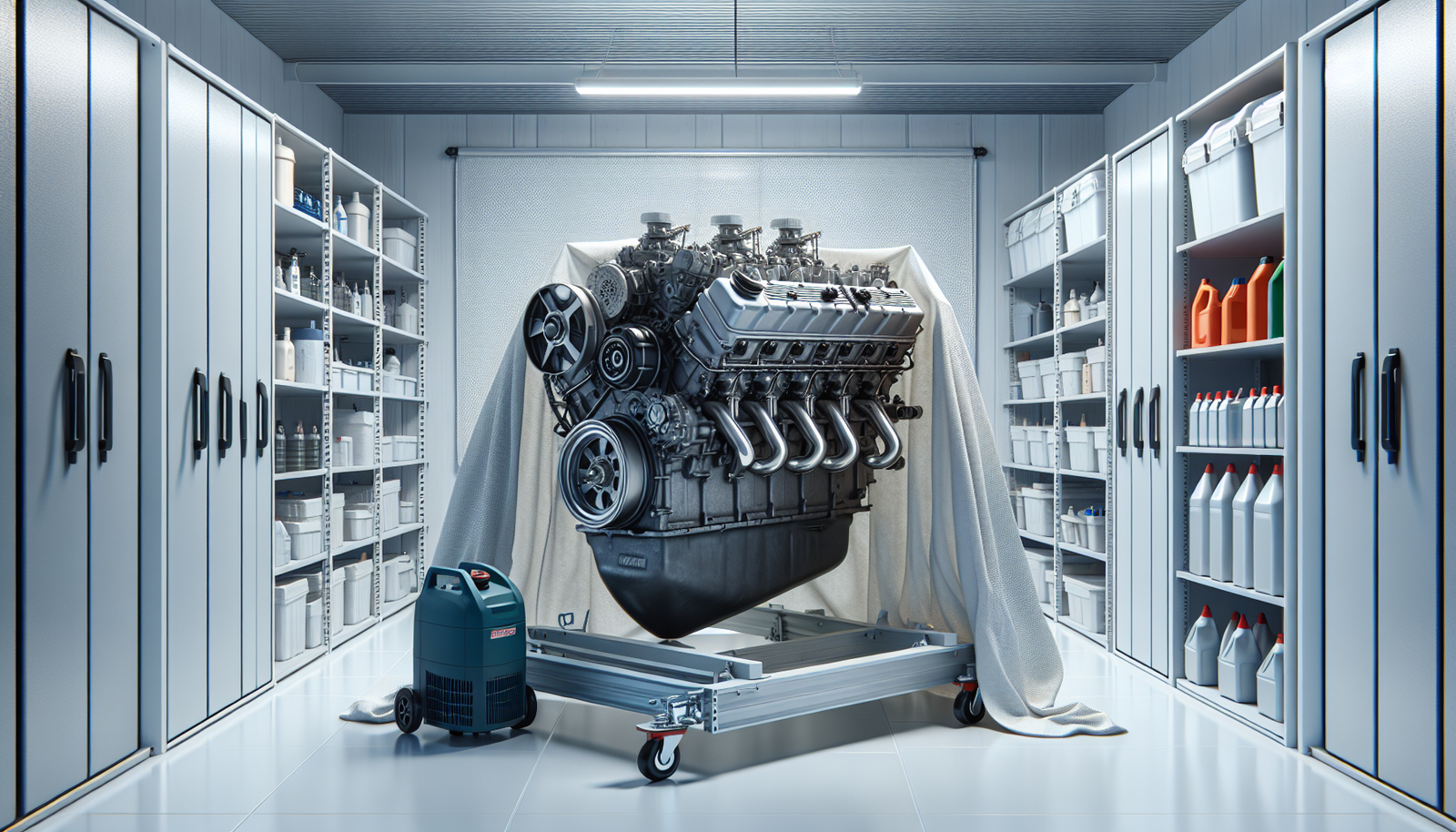

Covering the Engine

Finally, cover your engine with a suitable engine cover. This act would protect it from dust, rainwater, or any external elements that might harm it.

Maintaining the Propeller and Lower Unit

Your propeller and lower unit also need special attention.

Assessing and Repairing Damage

Before storing, assess for any scratches, dents, or bends in your propeller. Always consult an expert for any repairs.

Thorough Cleaning Techniques

Clean the propeller and the rest of the lower unit thoroughly, ensuring no small marine animals or vegetation are left behind.

Applying Grease to the Propeller Shaft

A good way to protect your propeller shaft is by applying waterproof marine grease. It prevents rust and helps maintain good operating conditions.

Dealing with Internal Components

Before we move on to the final phase, let’s discuss dealing with internal components.

Fogging the Engine’s Interior

Fogging engines with oil is a must-do. This process helps to slow down the corrosion process and keeps the cylinders from drying out.

Handling Spark Plugs

When it comes to spark plugs, first remove them and clean the areas around. After adding fogging oil, put a small amount of oil into the spark plug holes before replacing the plugs.

Dealing with the Fuel Line and Filters

Always remember to replace the fuel filters, and also give your fuel lines an inspection for any signs of damage or leaks.

Periodical Check During Storage

Right. Don’t forget about your boat entirely while it’s in storage.

Why Regular Checking is Necessary

Weather conditions may change, turning mildew into a challenge, and pests can decide to make your boat their new home. A regular check helps you avoid these and maintain a controlled environment.

Things to Look for During These Checks

During these checks, look out for signs of moisture, pests, and verify the level of battery charge.

Maintaining Optimal Storage Conditions

Maintain ideal conditions at all times. These checks and precautions contribute significantly to preserving your boat engine during its hibernation.

That’s it, folks. Properly storing your boat engine might seem like a herculean task at first, but remember, with care and attention, you can increase the lifespan of your boat engine, saving you from expensive repairs and unnecessary headaches down the line. Happy boating!