Navigating the open seas, your boat is your reliable companion. It’s unthinkable to imagine that unseen menaces like corrosion and rust could impair the heart of your vessel – the engine. “How to Protect Your Boat Engine from Corrosion and Rust” provides tried and tested strategies that will provide a shielding barrier to your engine, prolonging its life and performance. So whether you’re sailing towards clear horizons or sitting it out at the coastal beauty of a harbor, your boat remains steadfast, unblemished by the relentless attack of rust and damage.

Understanding Corrosion and Rust

You might have seen that reddish-brown flaky stuff on metal surfaces, particularly your boat engine and wondered what it is. Well, that’s what we call rust. But before we get there, let’s break down what corrosion is.

Definition of Corrosion

Corrosion is the process through which metals deteriorate due to the chemical reactions with their environment. This process is accelerated by factors such as moisture, saltwater, and oxygen. Essentially, corrosion is an electromechanical process that alters the properties of the metal, rendering it weak and ineffective.

Definition of Rust

When we come to rust, it’s important to note that it’s a specific type of corrosion – one that occurs in iron and its alloys, including steel. When exposed to moisture and oxygen, these iron-based metals go through a process called oxidization, resulting in the formation of iron oxide, commonly referred to as rust.

Factors leading to Corrosion and Rust

Several factors contribute to the acceleration of rust and corrosion, these include moisture, oxygen, and the presence of salts, particularly in marine environments. Changes in temperature and pH levels can also expedite the process. Rust and corrosion are a boat owner’s nightmare, particularly when it comes to affecting their boat engines.

Common Types of Metal Corrosion in Boat Engines

You should be aware of different types of metal corrosion that can occur in boat engines. There’s galvanic corrosion which is caused by the contact between two dissimilar metals in a conductive liquid. Then, there’s electrolytic or stray current corrosion where an electrical fault causes corrosion. Last but not least is atmospheric corrosion, occurring when metal is exposed to the air.

The Impact of Corrosion and Rust on Boat Engines

Corrosion and rust can have a devastating impact on boat engines, affecting performance, lifespan, and even safety.

Effect on Engine Performance

Corrosion can lead to the failure of essential boat engine components. Rusty parts may no longer be able to move freely or fit together properly. This can lead to reduced fuel efficiency, decreased power output, or more serious issues like engine failure.

Effect on the Lifespan of the Engine

Corrosion and rust also have a direct impact on the lifespan of your boat engine. Parts affected by rust are likely to fail sooner than expected, which might require costly repairs or replacements.

Safety Issues Linked to Rust and Corrosion

The safety implications of rust and corrosion should not be overlooked either. Corroded parts can suddenly break or fail, causing accidents or leaving you stranded in the middle of the water.

Identifying Signs of Corrosion And Rust on Boat Engines

Being able to spot corrosion and rust early on can make a big difference in terms of maintenance and prevention.

Visual Inspection for Rust and Corrosion

The first step is a thorough visual inspection. Look out for a change in color, often red or green, or the presence of white powdery substances on metal surfaces.

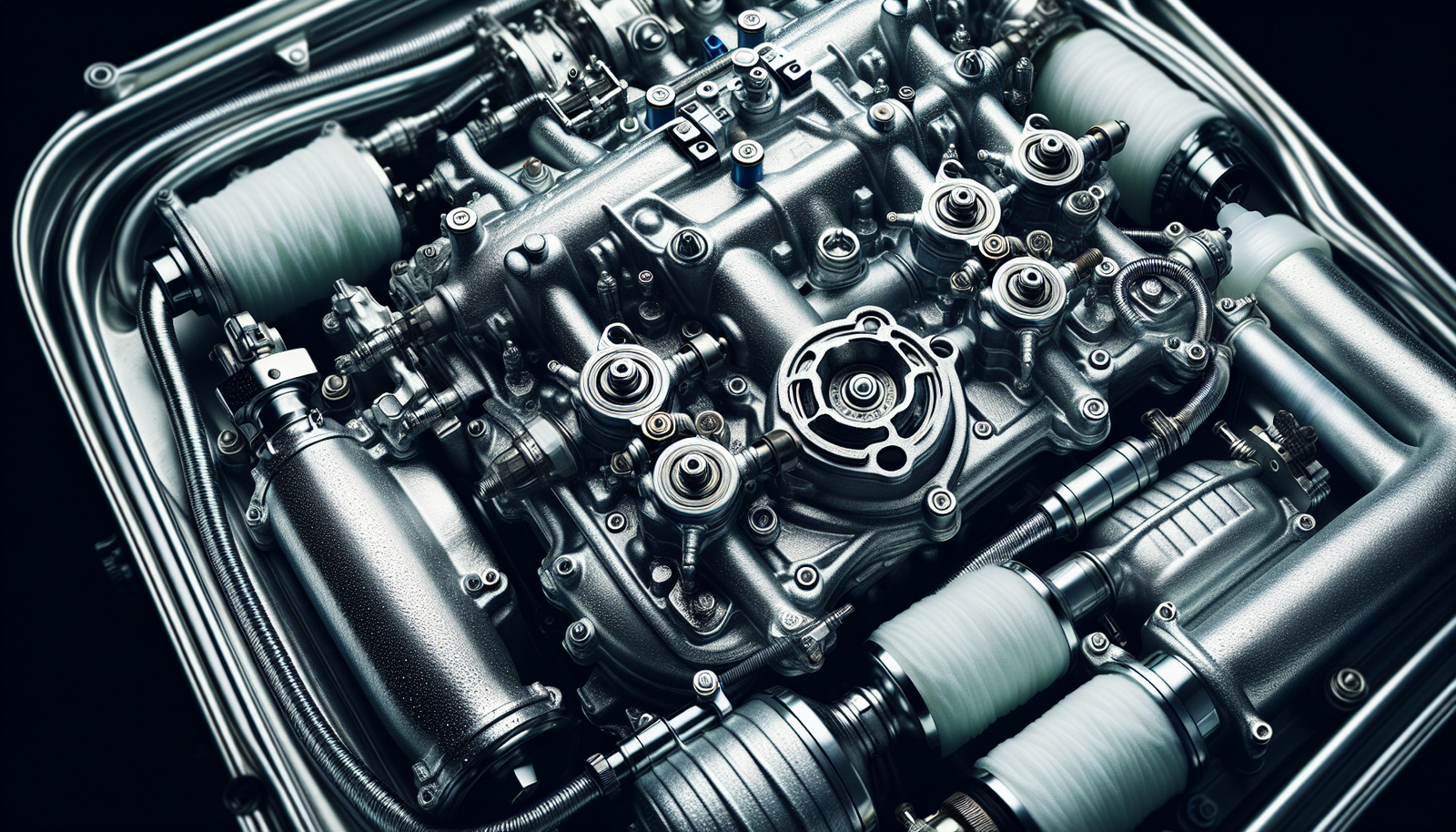

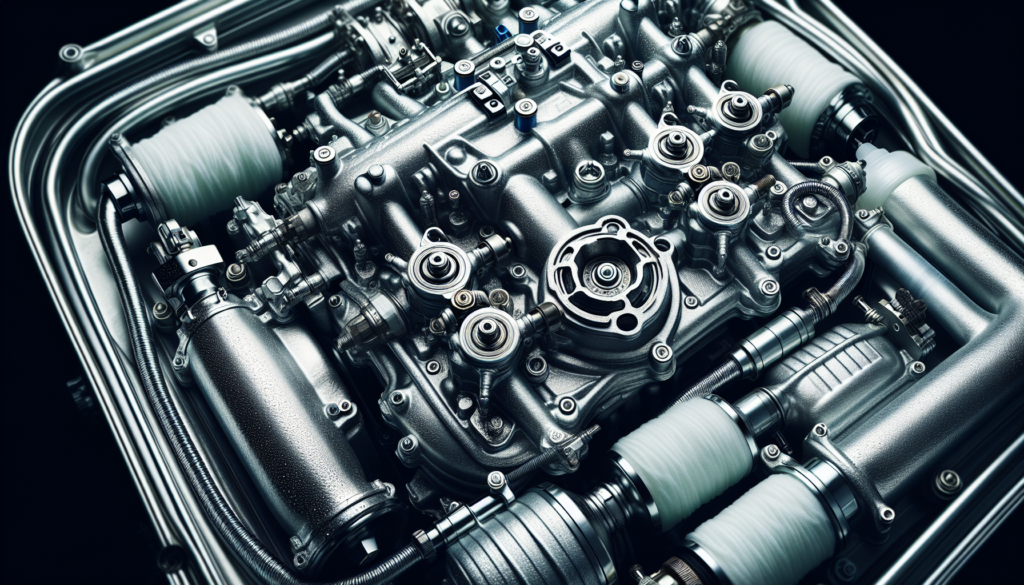

Common Locations of Corrosion on Boat Engines

While any part of a boat engine can be prone to rust or corrosion, some areas are more susceptible than others. These include the engine mount, propellers, exhaust manifold, and the cooling system.

Engine Performance Indicators of Possible Corrosion

In addition to physical inspection, be aware of any changes in your boat’s performance. Reduced speed, poor fuel efficiency, or failure to start might indicate that corrosion could be at play.

Preventive Measures Against Corrosion and Rust

As the saying goes, “Prevention is better than cure,” and it applies perfectly in the case of rust and corrosion on boat engines.

Proper Storage of Boats and Engines

How you store your boat can play a big role in preventing corrosion. This includes avoiding prolonged water exposure and storing the engine in a dry and ventilated area.

Effective Cleaning Habits

Regular cleaning is another effective way to prevent corrosion. This involves removing any salt, dirt, or foreign substances that can contribute to corrosion.

Using Anti-Corrosion and Anti-Rust Products

Applying anti-rust and anti-corrosion products such as paints, sprays, or coatings can provide a protective barrier against elements contributing to corrosion.

Regular Maintenance Check-ups

Regularly inspecting and maintaining your boat engine helps identify and address any signs of corrosion or rust before they cause significant damage.

Using Anti-Corrosion and Anti-Rust Products

Preventive products play a vital role in mitigating the effects of corrosion and rust on boat engines.

Types of Anti-Corrosion and Anti-Rust Products

These products come in various types, including sprays, paints, and coatings. Each has its own benefits and application methods, making them suitable for different types of metals and environments.

How to Select the Right Product

Choosing the right product should consider factors such as the type of metal, the severity of existing rust, and the environment in which the boat is stored or used.

Application of Anti-Corrosion and Anti-Rust Products

Regardless of the product type, the application should always begin with thoroughly cleaning and drying the metal surface. This ensures that the product adheres properly and provides effective protection.

Regular Boat Engine Maintenance

In the fight against corrosion and rust, regular maintenance stands as your first line of defense.

Importance of Regular Maintenance

Regular check-ups not only help detect early signs of corrosion but also ensure your engine runs smoothly and efficiently, extending its lifespan.

What Does Regular Maintenance Entail

Maintenance involves regular inspections, cleaning, lubrication of moveable parts, and applying anti-corrosion products. It’s also important to replace worn out or corroded parts promptly.

Working with Professionals in Boat Maintenance

Professional technicians have the necessary knowledge and expertise to detect and address any potential issues promptly and effectively. Consider utilizing their services for optimal engine care.

Understanding the Role of Anodes in Preventing Corrosion

Anodes, also known as sacrificial anodes, play a crucial role in protecting boat engines from corrosion.

Defining Anodes

Anodes are metal components deliberately installed on boats to protect other metal parts from corrosion. They do this by corroding themselves first – hence the term “sacrificial.”

How Anodes Prevent Corrosion

Anodes act as a “sacrificial lamb” by having a higher electrochemical potential than other engine parts. By doing so, they attract corrosive elements, thereby protecting the rest of the engine.

The Implication of Using Anodes in Saltwater Vs Freshwater

Different types of anodes are used depending on the water type. For example, zinc or aluminum anodes are suitable for saltwater, while magnesium anodes are ideal for freshwater environments.

How to Treat Already Corroded or Rusted Parts

Regular maintenance and preventive measures aren’t always enough. This is where treatment comes into play.

Identifying Treatable Vs Non-treatable Parts

Not all corroded parts can be treated. Severely corroded or damaged parts may need to be replaced instead. Early detection is the key to successful treatment.

Processes Involved in Treating Rusted or Corroded Boat Engine Parts

Treatment usually involves removal of the rusted parts, thoroughly cleaning them, followed by the application of corrosion inhibitors or coatings.

Determining When a Part Needs to Be Replaced Instead

If a part is too corroded or damaged that restoration is not possible, it’s time for a replacement. Also, if a part is crucial to the boat’s safety, replace instead of risking with repairs.

Mindful Boating Practices to Prevent Corrosion and Rust

Proper boating practices can also go a long way in preventing corrosion and rust.

Importance of Cleaning After Each Use

Thoroughly cleaning and drying your boat after each use will eliminate salts and other corrosion-causing elements.

Emphasis on Auberge and Storage Practices

Storing your boat in a dry and well-ventilated area can significantly reduce the likelihood of rust and corrosion.

Selecting the Right Materials for Your Boat and Engine

The type of materials used for your boat and engine also matter. Choosing durable, corrosion-resistant metals can make a big difference.

Dealing with Corrosion Caused by Electrical Systems in Boats

Electrical systems in boats can contribute to a unique kind of corrosion called electrolytic corrosion.

Understanding Electrolytic Corrosion

Electrolytic corrosion, or stray current corrosion, is caused when electric currents leak from a boat’s electrical system and pass through the boat’s metal hull into the water.

How Electrical Systems can Lead to Corrosion

This stray current triggers an electromechanical reaction causing the metal to corrode faster than usual. The result – your boat metal deteriorates at an accelerated rate.

Prevention of Electrolytic Corrosion

Its prevention involves regular electrical system check-ups to detect and fix any leaks, proper insulation of electrical parts, and efficient grounding of electrical systems.

In a nutshell, being a proactive boat owner, conducting regular inspections and maintenance, using the right materials, and employing good cleaning, storage, and boating practices can significantly reduce the risk of rust and corrosion to your boat engine.