You’ve decided to embark on a journey across the water and your boat has always been a faithful companion. Suddenly, there’s a hitch – an ignition problem that’s quite literally dampening your spirits. Let’s not let this hiccup ruin your day! All hands on deck, time to learn how to troubleshoot ignition problems in your boat engine. Navigate through this easily-digestible article as it sails through potential issues, their causes and how to solve them so you can get right back to your aquatic adventures. Change oil, shortcuts be damned, safety matters, maintain your boat! Let’s turn those cloudy skies into a clear horizon!

Understanding Ignition System Basics

When it comes to maintaining your boat, understanding the basics of the ignition system plays an important role. This is because the ignition system is the heartbeat of your boat’s engine. It is responsible for creating and distributing the electrical energy that allows your boat to start and run.

Fundamentals of Ignition System

The fundamental role of the ignition system is to initiate the combustion process within the engine. When you turn the ignition key, electrical energy surges from the battery to the spark plug, igniting the air-fuel mixture within the engine cylinders. This is what gives life to your engine and allows your boat to sail.

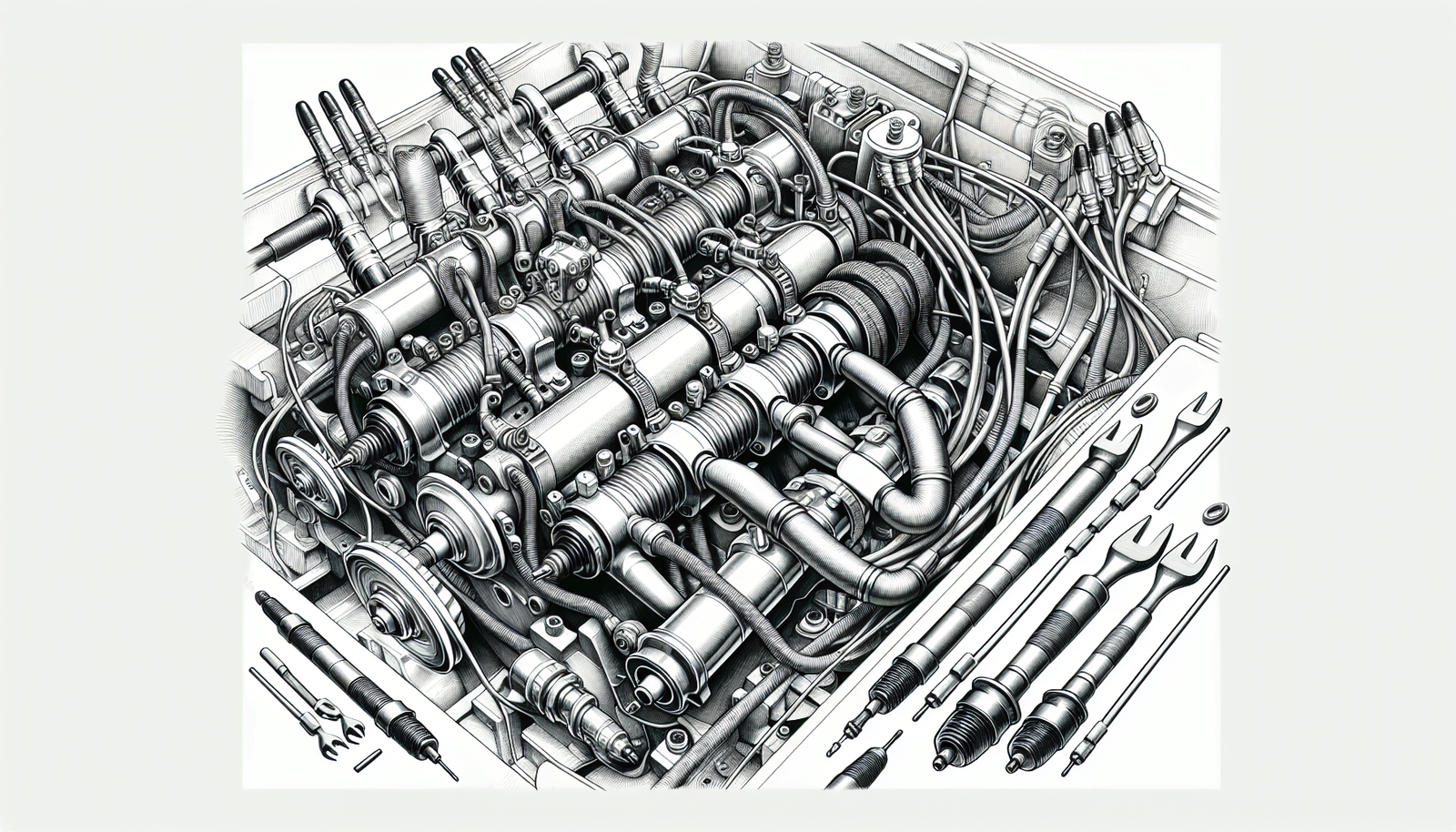

Key Components of the Ignition System

There are several key components of the ignition system you should familiarize yourself with. These include the ignition switch, which starts and stops the flow of electricity, and the ignition coil, which transforms low-voltage power from the battery into high-voltage power needed by the spark plugs. The distributor splits the power amongst the cylinders, while the spark plugs use this power to ignite the fuel in the engine.

How the Ignition System Works

The ignition system works through a sequence of tightly coordinated events. Once you turn the ignition switch, a current is sent from the battery to the ignition coil. Here, it is converted into a high-voltage charge, which travels to the distributor. The distributor rotates in synchronization with the engine, guiding the current to each spark plug at the right timing. The spark plug then ignites the air-fuel mixture, causing the engine to start.

Common Boat Ignition Problems

Like all machines, boat engines aren’t perfect and may sometimes experience ignition problems. Understanding these problems will help you to troubleshoot and fix them before they can escalate into serious issues.

Engine Won’t Start

One of the most common ignition problems is when the engine won’t start at all. This could be caused by various issues like a dead battery, a faulty starter motor, or a problem with the ignition switch. Faulty wiring or an engine that is not properly tuned can also cause the engine not to start.

Engine Starts But Does Not Run Properly

Another common problem is when the engine starts but sputters, idles roughly, or backfires. This usually indicates that the ignition timing is off. The root cause could be a faulty spark plug, distributor, ignition coil, or an issue with the ignition control module.

Engine Stops Abruptly

If your engine abruptly stops while the boat is running, the ignition system could have an issue. A faulty kill switch, malfunctioning ignition coil, or a failing ignition module could be causing the problem.

Inspecting the Starter System

To troubleshoot the ignition system, you need to inspect the starter system. The starter system is essentially the driver behind your boat’s ignition process, thus plays a crucial role in the overall functioning of your boat engine.

Checking the Starter Motor

Begin by examining the starter motor. The starter motor is responsible for generating the initial rotation of the engine. If it’s failing, it may cause the engine not to start or crank slowly. Listen for clicking or grinding sounds when trying to start the engine. If you hear any, the starter motor could be the issue.

Testing the Starter Solenoid

The starter solenoid acts as a relay, transferring high current from the battery to the starter motor. To test it, you can bypass the solenoid by connecting a jumper wire from the positive terminal of the battery to the starter motor. If the engine cranks, the solenoid might be faulty.

Evaluating the Battery Voltage and Cables

Lastly, check the battery voltage and cables. A fully charged battery should read around 12.6 volts. Damaged or worn out cables can also hinder the flow of current from the battery, preventing the engine from starting.

Examining the Ignition Switch

The ignition switch is another crucial component that often demands attention in the case of ignition problems.

Understanding the Role of the Ignition Switch

The ignition switch controls the flow of electrical energy from the battery to the ignition system. It essentially acts as the gatekeeper for your boat’s electrical system.

Troubleshooting a Faulty Ignition Switch

If your engine isn’t starting, or if it’s doing so intermittently, you might want to check your ignition switch. One way to troubleshoot a faulty ignition switch is by checking for loose connections or corroded terminals.

How to Test the Ignition Switch

Testing the ignition switch is a straightforward process. Using a multimeter, you can test the voltage at the output terminal of the switch. When the ignition switch is turned to the ‘start’ position, you should see a reading close to the battery voltage. If not, this could signify an issue with the ignition switch.

Analyzing the Pulse Coil and Ignition Coil

If your boat engine still has issues after checking the starting system and the ignition switch, the next components to investigate would be the pulse coil and the ignition coil.

Recognizing the function of Pulse Coil and Ignition Coil

The pulse coil is a part of the ignition system that sends signals to the ignition module and measures the position of the engine crankshaft. The ignition coil, on the other hand, transforms the battery’s low voltage into the thousands of volts needed to create an electric spark in the spark plugs.

Troubleshooting Ignition Coil Problems

An ignition coil that’s failing can cause the engine to run irregularly or not at all. Look for physical signs of wear or damage. If you notice oil leaks around the coil, it’s a good indicator that it’s time for a replacement.

Testing the Pulse Coil Performance

To test the pulse coil, also known as the trigger coil, use a multimeter to measure the resistance between its terminals. The reading should be within the manufacturer’s specified range. If it’s outside this range, the pulse coil might be faulty.

Observing the Spark Plugs

It’s hard to talk about ignition systems without mentioning spark plugs. They’re the tiny but significant parts that ignite the fuel within the engine cylinders.

Importance of Spark Plugs in the Ignition Process

Spark plugs are crucial in the ignition process as they facilitate the spark that ignites the air-fuel mixture in the combustion chamber. This creates an explosion that propels the pistons, hence driving the engine.

Symptoms of Faulty Spark Plugs

Common symptoms of faulty spark plugs include difficulty starting the engine, engine misfires, rough idling, and high fuel consumption. You might also notice a decrease in acceleration or the engine power.

How to Inspect and Clean Spark Plugs

Inspect spark plugs for signs of wear, damage, or buildup of deposits. A worn-out or damaged spark plug will have a worn electrode or a cracked insulator. Extensive buildup of deposits could also affect the performance of the spark plug. You can clean mild deposits using a wire brush and spark plug cleaner.

Looking into the Ignition Module

The ignition module is also another critical component to assess during ignition problems.

Basic Function of the Ignition Module

The ignition module is the electronic controller of the ignition system. It works in conjunction with the pulse coil to accurately control the ignition timing and duration.

Signs of a Bad Ignition Module

A faulty ignition module can cause a variety of issues, including engine misfires, poor acceleration, and stalling. You might also notice poor fuel economy or the vehicle might refuse to start.

Steps to Test the Ignition Module

Testing the ignition module involves checking its resistance using a multimeter. As with the pulse coil, the reading should fall within the manufacturer’s specified range.

Testing the Kill Switch and Safety Lanyard

Next on your list of checkpoints should be the kill switch and the safety lanyard.

Role of Kill Switch and Safety Lanyard

The kill switch and safety lanyard are essential safety features in many boats. They are designed to stop the engine instantly in case of an emergency or when the operator is thrown overboard.

Mishaps Due to Faulty Kill Switch or Safety Lanyard

A faulty kill switch or safety lanyard may cause the engine to shut off abruptly while in operation, or they may fail to switch off the engine during an emergency, posing a significant safety risk.

Testing the Kill Switch and Safety Lanyard

Testing them involves a simple procedure where you start your engine and pull out the safety lanyard. If the engine does not stop, then either your kill switch or safety lanyard might be faulty.

Assessing the Carburetor and Fuel Filter

Although they are part of the fuel system, the carburetor and the fuel filter can also affect the performance of the ignition system.

Knowing the Connection Between Ignition and Fuel System

The ignition and fuel system work closely to ensure efficient combustion in the engine. The carburetor is responsible for mixing the correct amount of fuel and air before it enters the engine, while the fuel filter screens out dirt and other particles that can clog the carburetor and affect the combustion process.

Symptoms of Carburetor or Fuel Filter Issues

Common symptoms of a clogged fuel filter or a malfunctioning carburetor include difficulty starting the engine, fluctuating engine power, and poor fuel economy. The engine might also stall or run unevenly.

Inspecting the Carburetor and Fuel Filter

Inspect the fuel filter for signs of clogs or buildup. If it is clogged, replace it. Similarly, a dirty carburetor will need cleaning or, in some cases, a complete overhaul.

Preventing Future Ignition Problems

Now that we’ve covered the most common ignition issues on boats and how to troubleshoot them, let’s delve into how you can prevent these problems in the future.

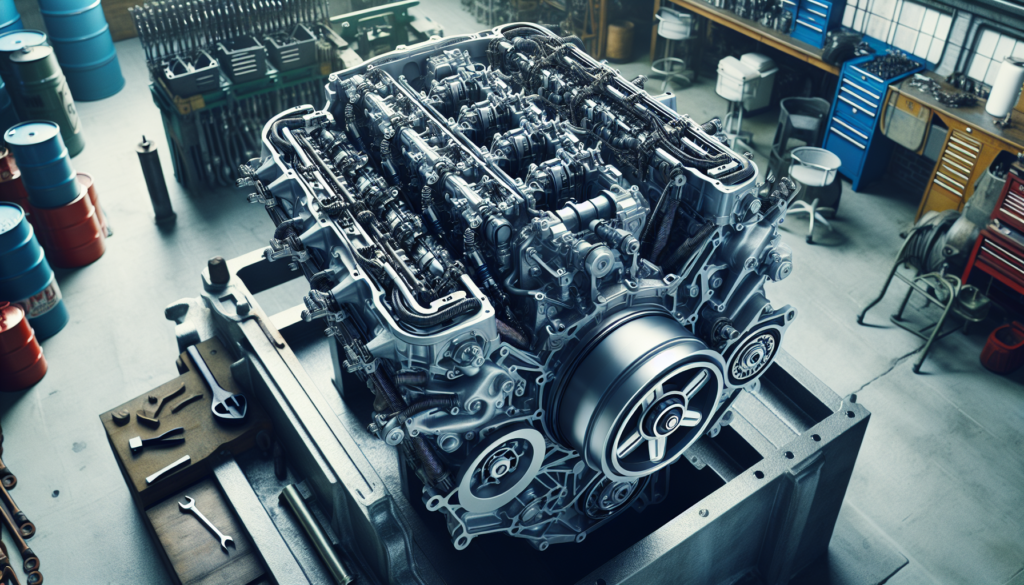

Routine Maintenance Tips for Ignition System

Routine maintenance of your boat’s ignition system involves regular inspections and replacements of failing components. Ensure to check and clean the spark plugs, battery, ignition switch, and all electrical connections. Regularly inspect the pulse coil, ignition coil, and ignition module for wear and ensure they are functioning as they should.

Importance of Using Quality Spare Parts

When replacing worn-out parts, it’s critical to use high-quality spare parts. Substandard parts may not function as expected and may cause more problems than they solve. Moreover, they may need frequent replacement, which means additional costs in the long run.

How to Store Your Boat to Prevent Ignition Problems

Proper boat storage is crucial in maintaining the robustness of your ignition system. Store your boat in a dry place and disconnect the battery to prevent any chances of corrosion. Further, run the engine dry or use a fuel stabilizer to prevent the fuel from breaking down and forming deposits in the carburetor. Maintaining your boat correctly increases its lifespan and ensures that every trip is memorable and worry-free.