With decades of innovations and technological advancements in boating, maintaining your boat’s engine has become more crucial than ever. Especially for those of you who enjoy saltwater boating, your engine maintenance practices can mean the difference between a thrilling day at sea and an unplanned soggy nightmare. “The Best boat engine upkeep practices for saltwater boating” offers a treasure trove of tips and practical advice to keep your boat’s engine in peak condition for those refreshing ocean adventures. This guide focuses on preventative measures, regular checks, and understanding the special needs that come with saltwater exposure. This isn’t just about keeping the engine running; it’s about extending its life and enhancing your overall boating experience.

Understanding Saltwater Corrosion

Saltwater corrosion can cause damage to your boat engine if not properly managed. It’s important to understand how saltwater corrosion works, both chemically and practically, in order to best maintain your boat’s engine.

The chemistry of saltwater corrosion

At a molecular level, saltwater corrosion occurs when saltwater interacts with the metal components in your boat engine. The salt speeds up the process of oxidation, and this can cause corrosion damage over time. This form of corrosion is well known for its destructive power on metals due to the harsh chemical reactions it induces.

How saltwater affects boat engines

Saltwater has a very tangible impact on boat engine. It accelerates the corrosion process. When this happens, it leads to rust, which can cause damage to engine parts such as the cooling system, gearbox, exhaust system, and even to the engine block itself.

The role of temperature and humidity

Temperature and humidity can exacerbate saltwater corrosion. Hot, humid climates, especially in conjunction with regular saltwater exposure, can accelerate the rusting process. The salt crystals left behind by evaporated water can bind to the engine, exacerbating wear and tear.

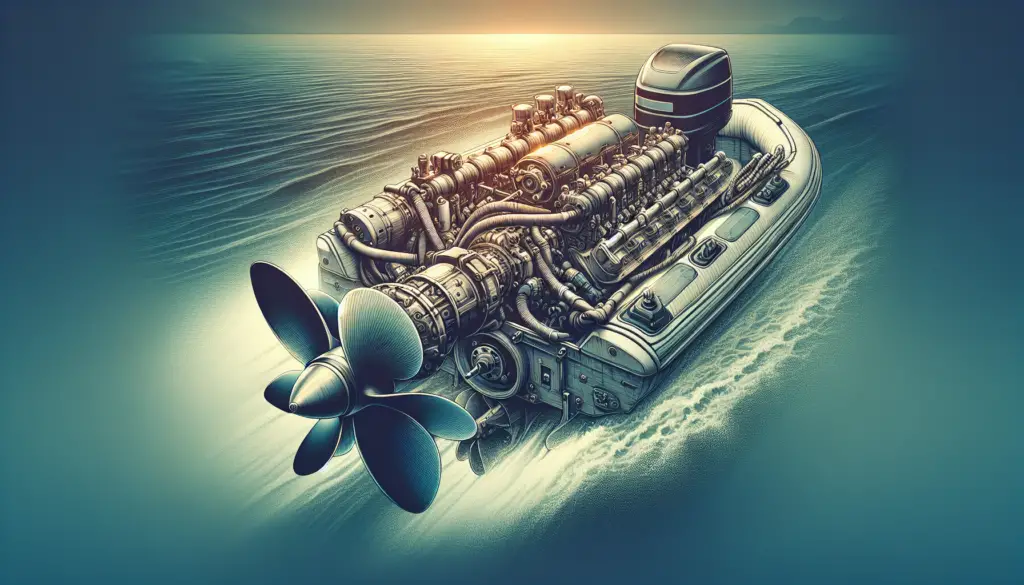

Types of Boat Engines

Just as there are many types of boats, there are also different types of boat engines, each with their own unique characteristics and maintenance needs.

Inboard engines

Inboard engines are those located inside the boat’s hull. They’re commonly found in larger boats and provide a lot of power. However, their location inside the boat can make them more susceptible to saltwater damage, and they may require more in-depth maintenance.

Outboard engines

Outboard engines, on the other hand, are mounted on the outside of the boat. They’re easier to maintain and repair than inboard engines, making them popular among small boat owners. They can also be lifted out of the water when not in use, reducing their exposure to saltwater.

Sterndrive engines

A sterndrive engine strikes a balance between inboard and outboard engines. It’s installed inboard for better weight distribution, but driveshaft and propeller are outside, like an outboard. This unique design means that sterndrive engines share maintenance traits with both inboard and outboard engines.

Routinely Inspecting the Engine

Frequent inspection of your boat engine is critical, especially when often boating in saltwater.

The importance of regular checks

Regular checks can prevent small issues from becoming major problems. Inspecting your boat engine routinely allows you to catch signs of wear and tear or corrosion early on, allowing you to address issues before they cause more serious damage.

Identifying problem signs

Certain signs may indicate problems with your engine. Look out for signs of rust, which indicates corrosion. Other signs could include unusual noises, a drop in engine performance, or leaks of oil or coolant. If you notice these signs, it may be time for maintenance or repair.

Dealing with corrosion or damage

Corrosion or damage should be addressed immediately to prevent further issues. Depending on the extent of the damage, you may require professional assistance. If caught early, you might be able to treat minor corrosion with an anti-corrosion product.

Flushing the Engine After Use

Proper maintenance after use, especially in saltwater, is crucial to expanding the lifespan of your boat engine.

Why flushing is necessary for saltwater boating

Saltwater can lead to corrosion and buildup in your engine. Flushing your engine after every use can rinse away the salt and prevent these problems from occurring.

How to flush your boat engine

To flush your boat engine, connect a hose to the engine’s flushing port and let fresh water run through for several minutes. Make sure the engine is turned off when you’re flushing it. For thorough cleaning, you might need engine flushing products designed for saltwater boating.

When to flush your engine

Ideally, you should flush your engine after every use in saltwater. But if that’s not feasible, at least aim for a regular weekly or bi-weekly flushing schedule.

Cleaning the Boat Engine

After flushing the boat engine, the next step is to clean it thoroughly. This helps get rid of any remaining salt or other particles that might damage the engine.

Importance of cleaning the engine

Regular cleaning can prevent potential damage from saltwater and other debris. It allows your boat engine to run more efficiently, ensuring lasting performance and longer lifespan.

Materials and solutions to use

There are a variety of cleaning products available specifically for boat engines that can break down salt, grease, and other contaminants. A simple scrub brush and soap can also do the trick for lightly soiled areas.

Steps to thoroughly clean engine

Start by disconnecting the battery and covering any delicate parts. After applying the cleaner, scrub to break up any deposits. Rinely thoroughly, ensuring no cleaning solution is left behind, then dry properly to reduce moisture.

Using Anti-Corrosion Products

Anti-corrosion products play a crucial role in prolonging the life of a boat engine used in saltwater.

Types of anti-corrosion products

Anti-corrosion sprays, coatings, and greases are all available to help protect your engine. These products are designed to create barriers between the metal components of your engine and the destructive force of saltwater.

How and where to apply

Anti-corrosion products can be applied to any exposed metallic parts of the engine. Make sure to read and follow the product instructions for the best results.

Choosing the best anti-corrosion product for your engine

When selecting an anti-corrosion product, consider your engine type and the product’s effectiveness against saltwater corrosion. Product reviews and recommendations can be useful in making a decision.

Regular Oil Change and Check-up

Just like a car, your boat engine requires regular oil changes and check-ups to operate efficiently.

Why oil change is crucial for saltwater boats

Oil changes remove contaminants and ensure that the engine parts remain well-lubricated. In a saltwater environment, oil changes are even more crucial as saltwater can expedite the deterioration of engine oil.

How to change oil correctly

Changing engine oil involves draining the old oil, changing the oil filter, and adding new oil. Always consult your engine manufacturer’s instructions for specific details.

Frequency of oil change for saltwater boats

For boats often used in saltwater, it’s best to change the oil at least once every 50 to 100 operating hours, or every six months – whichever comes first.

Maintaining the Cooling System

The cooling system is vital for keeping your engine at optimal operating temperature.

Understanding the engine’s cooling system

Boat engines typically utilize a closed cooling system, that keeps the engine cooled by circulating coolant. Understanding how it works is crucial for proper maintenance.

Identifying issues in the cooling system

Signs of problems with the cooling system can include overheating, coolant leaks, or a decrease in performance. Regular inspections can help detect these early.

Maintaining and repairing the cooling system

Regular maintenance of the cooling system includes flushing and filling it with fresh coolant. Damaged parts should be repaired or replaced immediately to prevent engine overheating.

Taking Care of The Fuel System

Just as vital as the engine and cooling system, is the boat’s fuel system.

Why fuel system care is vital for saltwater boating

The fuel system is prone to corrosion and clogging due to saltwater and other contaminants. Proper maintenance is necessary for smooth engine performance.

How to clean and maintain the fuel system

Regularly changing fuel filters and making sure the fuel tank is clean can help maintain the system. Periodic checks on fuel lines and fittings can help spot potential issues.

Tips for fuel efficiency in saltwater boating

Prevent fuel wastage by only filling the tank to around 90% capacity, ensuring the boat is well-trimmed before acceleration, and keeping the hull clean of any debris.

Professional Maintenance and Repair

Despite your best efforts, sometimes professional help is needed to maintain your boat engine.

When to seek professional help

If you’re experiencing persisting issues with your boat engine that you can’t diagnose or fix yourself, it might be time to seek professional help.

Choosing a reliable maintenance service

When choosing a maintenance service, make sure to select a reputable provider with positive reviews and solid experience. Good communication and a clear understanding of the costs and process are important too.

Understanding maintenance costs and schedules

Understanding the costs associated with professional boat engine maintenance can help you budget effectively. Regular scheduled maintenance can often prevent expensive repairs down the line.

In conclusion, taking good care of your boat engine begins with understanding how saltwater affects it and taking the necessary steps to mitigate against corrosion and other potential damage. The right practices can ensure a long lifespan for your boat’s engine and ultimately save you from costly repairs.