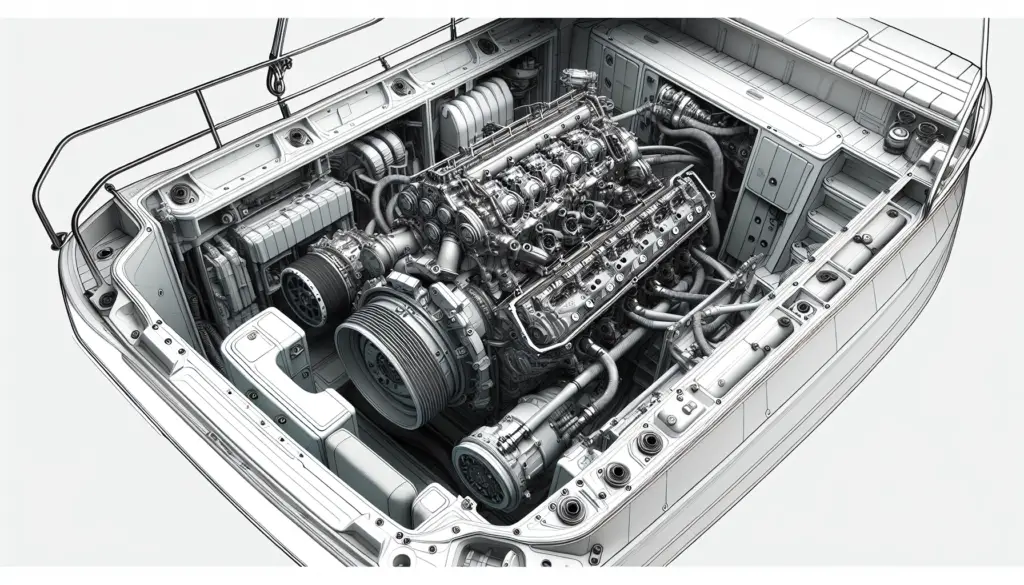

Navigating through the intricacies of boat engine emission control technologies can be a tricky task for those unfamiliar with them. In the article, “The Most Common Boat Engine Emission Control Technologies Explained”, you will walk through the most frequently used methods, their pros and cons, and how they contribute to maintaining a clean and green aquatic environment. From devices reducing the exhaust pollutants to technologies minimizing the presence of harmful chemicals, you’ll gain a comprehensive understanding of how these innovations curb pollution and promote sustainable boating practices.

Catalytic Converter

Getting a grip on your beloved engine means understanding its different components. One of these is the Catalytic Converter. Let’s dive into what this is all about, shall we?

Fundamentals of Catalytic Converters

Alright, let’s start with the basics. A catalytic converter is a device that plays a crucial role in reducing harmful emissions from your engine. Do you remember all that chatter about reducing carbon emissions for environmental reasons? Yup, this is where catalytic converters step in. By transforming harmful gases into less harmful substances before emission, they contribute significantly towards maintaining a cleaner, safer atmosphere.

Working Mechanism

Let’s explore the magic that goes on inside these converters. A catalytic converter uses catalysts to facilitate chemical reactions that convert harmful components of exhaust gas into harmless substances. Simply put, it’s a converter that acts as a transition place where bad stuff is transformed into good stuff.

Role in Emission Control

Here’s why you should appreciate your catalytic converter. It handles pollutants in three parts: unburnt hydrocarbons, nitrogen oxides, and carbon monoxide. These harmful gases get converted into carbon dioxide, nitrogen and water, which are relatively harmless. Thanks to catalytic converters, we can breathe easy (pun intended!).

Muffler System

Pardon me, did I hear a rumble? Ah, that’s your engine’s muffler system.

Purpose of Muffler System

Here’s the tea on mufflers. The purpose of a muffler system is to reduce the noise produced by the exhaust gases that are expelled from an internal combustion engine. Remember all those times you’ve been annoyed by noise from exhaust pipes? You can thank a bad muffler for that.

Design and Operation

Your muffler system’s design and operation are pretty straightforward. Sound waves created by the engine are directed into the chamber of the muffler. Here they bounce around, cancelling each other out and thus reducing noise levels.

Emission Reduction Techniques

Nope, mufflers aren’t just about noise control. Modern muffler systems are designed to deal with emissions too. They incorporate Catalytic Converters or Diesel Particulate Filters that capture and convert harmful pollutants into less harmful substances.

Fuel Injection System

Let’s talk about something vital: your fuel injection system.

Basics of Fuel Injection System

Your fuel injection system is like the cardiovascular system of your boat engine. It supplies your engine with the necessary fuel at the right time, in the right quantity, and at the correct pressure.

Types of Fuel Injection

Your fuel injection system comes in two main types: indirect and direct. Indirect injection is where fuel is injected into the intake manifold or cylinder head before reaching the combustion chamber. Direct injection, on the other hand, involves injecting fuel directly into the combustion chamber. Both have their pros and cons.

Importance in Emission Control

Here’s why fuel injection is essential for emission control. By regulating the amount of fuel that enters the combustion chamber, it minimizes the production of harmful exhaust gas components. It’s like a gatekeeper deciding who gets to enter the party!

Exhaust Gas Recirculation

Exhaust Gas Recirculation – sounds complex, doesn’t it? Let’s break it down.

Understanding Exhaust Gas Recirculation

Exhaust Gas Recirculation (EGR) is a method used to reduce nitrogen oxide emissions from engines. It does this by recirculating a part of an engine’s exhaust gas back to the engine cylinders. It’s like giving your engine a second chance to deal with those pesky nitrogen oxides!

Different Methods Used

There are a few ways EGR is used. Some methods include using a valve controlled by the engine control unit, a venturi system, or a system that combines both.

Contribution to Emission Control

EGR doesn’t just toss around exhaust gas for fun. By lowering combustion temperature, it reduces the amount of nitrogen oxides produced. So the next time you see EGR, think less pollution!

Air Injection System

Ever heard of an air injection system? Well, it’s high time you did!

Concept of Air Injection System

The concept of an air injection system is to introduce fresh air into the exhaust stream. Amazing, right?

Functioning Process

This system functions like a proactive friend who steps in before things get messy. It injects additional air into the exhaust system to ensure the complete combustion of harmful gases. The result? You guessed it – less pollution.

Influence on Emission Levels

By ensuring that harmful gases are fully combusted, air injection systems positively impact emission levels. This results in cleaner air and less damage to the environment.

Emission Control System Sensors

Hold on, we’re not done yet. There’s another great soldier in the emission control battle: sensors!

Need for Sensors in Emission Control

Sensors in emission control systems are like intelligence officers. They gather information on various factors, like oxygen levels, temperature, pressure, and more, to keep your engine running smoothly and cleanly.

Most Commonly Used Sensors

Among the most commonly used sensors are oxygen sensors and temperature sensors. These can adjust your engine systems for optimal performance and minimal emissions.

Role in Moderating Emissions

These tiny warriors’ role in moderating emissions is immense. They provide essential information to the engine control unit, which adjusts engine operation accordingly to minimise both fuel consumption and emissions.

Closed Crankcase Ventilation System

Ready to understand another key player? Ladies and gents, the Closed Crankcase Ventilation System!

Introduction to Closed Crankcase Ventilation

A Closed Crankcase Ventilation (CCV) system is used in your engine to prevent oily mist and other unwanted blow-by gases from being released into the environment. It incorporates more of the good stuff and less of the bad.

How it Functions

Your CCV system captures crankcase vapours and directs them back into the engine, where they’re combusted and sent out through the exhaust. It’s a little bit like the engine tidying up after itself.

Significance in Controlling Emissions

You can imagine the impact such a system has on emission control. A CCV system prevents not only oil mist but also unburned hydrocarbons, carbon monoxide, and even trace amounts of fuel from escaping into the atmosphere.

Marine Scrubbers

Ready to delve into marine scrubbers a bit? Let’s go!

Principle of Marine Scrubbers

Marine scrubbers, also known as Exhaust Gas Cleaning Systems, are essential in modern vessels. They help clean exhaust gas by neutralizing harmful components before they’re released into the environment.

Working of Marine Scrubbers

A marine scrubber works by using a scrubbing agent, like seawater or a basic solution, to capture and neutralize sulfur oxides present in the exhaust gas.

Impact on Emission Levels

By reducing sulfur oxides and particulate matter, marine scrubbers have a massive influence on emission levels and contribute significantly to environmental conservation efforts.

Selective Catalytic Reduction

This might sound intimidating, but don’t worry, I’ll keep it simple.

Understanding Selective Catalytic Reduction

Selective Catalytic Reduction (SCR) is a technology that reduces nitrogen oxide emissions using ammonia as a reductant within a catalytic system. Yet another ally in our fight against harmful emissions!

Procedure of Operation

In this process, a mix of ammonia and exhaust gas is passed over a catalyst, which triggers a reaction that breaks nitrogen oxides down into nitrogen and water – both harmless and naturally occurring substances!

Importance in Emission Reduction

SCR is enormously significant in reducing emissions, especially in engines that rely on high combustion temperatures, where nitrogen oxide emissions tend to be higher.

Evaporative Emission Control System

Ever thought about your fuel tank emissions? Let’s talk about the Evaporative Emission Control System.

Basics of Evaporative Emission Control

An Evaporative Emission Control (EEC) system is meant to prevent fuel vapors from your fuel system from escaping into the atmosphere. It’s the custodian of your fuel tank!

System Components

An essential part of the EEC system is its activated carbon canister, which captures fuel vapours when your engine isn’t running. Once your engine starts, these vapours are purged from the canister and used in the combustion process.

Emission Control Ability

Through this ingenious process, the EEC system significantly reduces the amount of fuel vapor emissions, contributing to a cleaner environment.

So there you have it! A comprehensive deep dive into your engine’s emission control technologies. Badass stuff, right? It just goes to show the extent to which technology works towards minimizing our impact on the environment. So next time you’re enjoying your boat ride, remember to give a silent nod to these hardworking systems, quietly protecting our precious environment.