If you’re a boat enthusiast looking to enhance the performance of your boat’s engine, you’ve come to the right place. In this article, we will explore the top 5 performance modifications for boat engines that can take your boating experience to the next level. From optimizing fuel efficiency to increasing horsepower, these modifications are sure to make a noticeable difference in your boat’s performance on the water. So, grab your captain’s hat and let’s dive into the world of boat engine upgrades.

1. Superchargers

1.1 Benefits of Superchargers

superchargers are a popular performance modification for boat engines, offering several benefits to enhance your boating experience. One of the main advantages of a supercharger is increased power output. By forcing more air into the engine, superchargers provide a significant boost in horsepower and torque, allowing your boat to accelerate faster and reach higher speeds.

Another benefit of superchargers is improved throttle response. With a supercharged engine, you’ll notice a more immediate and smooth response when you press the throttle. This can make maneuvering through tight spots or navigating rough waters much easier and more precise.

Superchargers also contribute to better overall engine performance and efficiency. By increasing the air intake, superchargers help optimize the fuel and air mixture, resulting in better combustion and improved fuel economy. Additionally, superchargers can enhance the engine’s cooling system, preventing overheating during intense use.

1.2 Types of Superchargers

There are two main types of superchargers commonly used in boat engine modifications: centrifugal and positive displacement.

Centrifugal superchargers operate by compressing the incoming air using a rotating impeller. They are known for their efficiency and linear power delivery. Centrifugal superchargers work best at high RPMs, making them suitable for applications that require top-end power, such as racing boats.

Positive displacement superchargers, on the other hand, use a pair of meshing lobes or screws to force air into the engine. They provide instant and consistent power across the entire RPM range, making them ideal for recreational boating or applications that require low-end torque, like cruising or towing.

1.3 Installation Considerations

When considering the installation of a supercharger in your boat engine, it’s important to take several factors into account. Firstly, ensure that the supercharger is compatible with your engine and that it can handle the increased stress and strain produced by the additional power. Consulting a professional mechanic or engine specialist is highly recommended to ensure a smooth and successful installation.

Additionally, consider any space limitations in your boat’s engine compartment. Superchargers can be bulky, so it’s crucial to ensure that there is enough room for proper installation without obstructing other engine components or compromising airflow.

Also, bear in mind that superchargers require regular maintenance and servicing to ensure optimal performance and longevity. It’s important to follow the manufacturer’s guidelines regarding maintenance intervals and procedures to keep your supercharged engine running smoothly.

2. Engine Tuning

2.1 Importance of Engine Tuning

engine tuning is a crucial aspect of maximizing the performance of your boat’s engine. Proper tuning ensures that all the components and systems in your engine are working harmoniously, resulting in improved power, efficiency, and reliability.

One of the main reasons to tune your boat’s engine is to optimize fuel combustion. By adjusting the air and fuel mixture, ignition timing, and other engine parameters, you can achieve a more efficient and complete combustion process, resulting in increased power output and reduced fuel consumption.

Engine tuning also allows you to adapt your engine’s performance to specific boating conditions or preferences. For example, you can fine-tune your engine’s power delivery for smoother acceleration or set it up for maximum speed. Additionally, tuning can help address any performance issues or limitations that may arise due to modifications or wear and tear.

2.2 Different Tuning Methods

There are various methods available to tune a boat engine, ranging from basic adjustments to more advanced modifications.

One of the simplest tuning methods is adjusting the air and fuel mixture using the carburetor or electronic fuel injection (EFI) system. This involves finding the optimal balance between air and fuel delivery to achieve the best performance and efficiency.

Another approach is modifying the ignition timing. Advancing or retarding the ignition timing can help optimize power delivery and prevent engine knock or detonation, which can cause damage.

For more advanced tuning, aftermarket engine management systems can be installed. These systems allow for precise control and customization of various engine parameters, such as air-fuel ratio, ignition timing, and even turbocharger or supercharger boost levels.

2.3 Optimizing Fuel and Air Ratio

Achieving the perfect fuel and air ratio is essential for optimal engine performance. The air-fuel ratio refers to the ratio of air to fuel in the combustion process. For most boat engines, the ideal air-fuel ratio is around 14.7 parts of air to 1 part of fuel, known as a stoichiometric ratio.

To optimize the fuel and air ratio, you can make adjustments to the carburetor or EFI system. This involves finding the right balance between fuel delivery and air intake based on factors such as engine load, RPM, and atmospheric conditions.

Using wideband oxygen sensors and air-fuel ratio meters can provide real-time feedback on the engine’s combustion efficiency, allowing you to make precise adjustments to achieve the ideal air-fuel ratio.

Proper tuning of the fuel and air ratio not only improves power and efficiency but also reduces emissions and minimizes the risk of engine damage caused by running too lean or too rich.

3. Exhaust Systems

3.1 Benefits of Upgrading Exhaust Systems

Upgrading the exhaust system of your boat engine can have several advantages that contribute to overall performance and enjoyment on the water.

One of the main benefits is increased horsepower and torque. Upgraded exhaust systems are designed to enhance exhaust gas flow, reducing backpressure and allowing the engine to breathe more freely. This results in improved power output, especially at higher RPMs, where backpressure can significantly limit performance.

Another advantage of upgrading the exhaust system is the enhanced sound. Many boaters appreciate a deep and powerful exhaust note, which can add to the overall boating experience. Upgraded exhaust systems often provide a more robust and aggressive sound, giving your boat a distinct and commanding presence on the water.

Additionally, a well-designed exhaust system can help improve fuel efficiency. By optimizing exhaust gas flow and reducing backpressure, the engine can operate more efficiently, resulting in improved fuel economy and reduced emissions.

3.2 Types of Exhaust Systems

There are several types of exhaust systems available for boat engines, each offering unique characteristics and performance benefits.

The most common type is a cat-back system, which includes all components of the exhaust system behind the catalytic converter. Cat-back systems are relatively easy to install and provide noticeable gains in horsepower and torque. They are also known for enhancing the exhaust sound without compromising emissions compliance.

Another popular option is a header-back system, which includes all components of the exhaust system from the engine’s exhaust ports to the rear of the boat. Header-back systems are more involved to install but offer greater performance gains, especially at higher RPMs. They also provide a more aggressive exhaust note.

For maximum performance gains, some boaters opt for a complete custom exhaust system. These systems are specifically designed and fabricated to suit the individual boat’s engine and performance requirements. Custom exhaust systems offer the highest level of customization and performance but can be more expensive and time-consuming to install.

3.3 Selecting the Right Exhaust System

When selecting an exhaust system for your boat, there are several factors to consider. Firstly, ensure that the exhaust system is compatible with your engine and meets any regulatory requirements, such as emission standards and noise regulations.

Consider the intended use of your boat and your performance goals. If you primarily use your boat for recreational purposes, a cat-back or header-back system may be sufficient to enhance performance and sound. However, if you engage in racing or high-performance boating, a custom exhaust system may be worth the investment to achieve maximum gains.

It’s also essential to consider the materials used in the construction of the exhaust system. Stainless steel is a popular choice due to its durability and resistance to corrosion, making it suitable for marine environments. Additionally, look for exhaust systems that offer good warranty coverage and reputable brand support for peace of mind.

Overall, selecting the right exhaust system for your boat engine involves finding a balance between performance, sound, regulations, and budget.

4. Propeller Upgrades

4.1 Understanding Propeller Anatomy

The propeller is a vital component of a boat’s propulsion system, and upgrading it can significantly impact the performance and efficiency of your boat.

Before diving into propeller upgrades, it’s important to understand the key components of a propeller. The hub is the central part that connects to the boat’s propeller shaft. It contains the splines or keyways that match with the propeller shaft, allowing the propeller to be securely mounted.

The blades of a propeller are responsible for generating thrust and should be carefully engineered and designed to achieve optimal performance. The pitch of the propeller refers to the distance the propeller should move forward with each full rotation. A higher pitch propeller will provide a higher top speed, while a lower pitch propeller improves acceleration and pulling power.

Additionally, propellers can have different numbers of blades, with three and four blades being the most common. Three-blade propellers generally provide better top speed, while four-blade propellers offer improved low-speed handling and acceleration.

4.2 Factors to Consider for Propeller Upgrades

When considering a propeller upgrade, there are several factors to take into account. Firstly, consider the boat’s intended use and performance goals. If you’re looking for increased top speed, a higher pitch propeller may be suitable. Alternatively, if you need better low-speed maneuverability or towing capability, a lower pitch propeller with more blades may be preferable.

Consider the engine’s power output and torque characteristics. The propeller should be matched to the engine’s capabilities to ensure optimal performance and efficiency. Consulting with a boat propeller specialist or a knowledgeable mechanic can help determine the best propeller size and configuration for your boat and engine combination.

Take into account the boat’s weight and hull design. Different boats have varying weight distributions and hull shapes, which can affect the ideal propeller characteristics. Factors such as trim tabs, jack plates, and other modifications should also be considered when selecting a propeller.

Finally, consider the specific water conditions in which you typically boat. Propeller performance can be affected by factors such as altitude, temperature, and water density. Taking these factors into consideration can help ensure that the selected propeller will perform optimally in your usual boating environment.

4.3 Choosing the Right Propeller

Choosing the right propeller for your boat requires careful consideration of various factors. It’s recommended to consult with a propeller specialist or a reputable boat dealer who can guide you through the selection process.

Professional propeller shops often have sophisticated tools and software to analyze your boat’s performance characteristics and recommend the best propeller options. They can consider factors such as engine specifications, boat weight, hull design, and performance goals to provide a tailored recommendation.

Keep in mind that propeller selection is not a one-size-fits-all approach. Different boats and engines have unique requirements, and the right propeller can make a significant difference in performance and efficiency.

Investing in a quality propeller and ensuring it is properly sized and matched to your boat’s specifics can greatly enhance your boating experience, providing better acceleration, top speed, handling, and fuel efficiency.

5. Fuel System Enhancements

5.1 Importance of Fuel System Enhancements

Enhancing the fuel system of your boat engine is an effective way to improve performance, reduce emissions, and optimize fuel efficiency.

By upgrading various components of the fuel system, you can ensure proper fuel delivery to the engine and maximize the combustion process. This results in improved power output, smoother acceleration, and reduced fuel consumption.

Fuel system enhancements also play a crucial role in addressing the demands of performance modifications such as superchargers or engine tuning. These modifications often require increased fuel flow to accommodate the additional power, and upgrading the fuel system becomes necessary to maintain optimal performance.

5.2 Fuel Injectors and Pumps

One of the key components of the fuel system is the fuel injector. Fuel injectors are responsible for delivering precise amounts of fuel into the engine’s combustion chambers. Upgrading to high-flow fuel injectors allows for increased fuel flow, which is essential for achieving greater power outputs.

Another important component is the fuel pump. The fuel pump is responsible for supplying fuel from the fuel tank to the engine. Upgrading the fuel pump to a high-performance or aftermarket unit can ensure adequate fuel delivery under high-demand conditions, such as high RPM or heavy throttle applications.

When upgrading fuel injectors and pumps, it’s crucial to select components that are compatible with your boat’s engine and fuel system. Consult with a fuel system specialist or an engine mechanic who can recommend the right components based on your specific requirements and modifications.

5.3 Fuel Filters and Pressure Regulators

Fuel filters and pressure regulators are often overlooked components of the fuel system, but they play a critical role in maintaining proper fuel quality, flow, and pressure.

Fuel filters are designed to remove contaminants and impurities from the fuel, preventing them from reaching the engine and causing potential damage. Regularly replacing fuel filters or upgrading to higher-performance filters can ensure clean fuel delivery and protect the engine from harmful particles.

Pressure regulators are responsible for maintaining a consistent fuel pressure in the system. Upgrading to a high-performance or adjustable pressure regulator allows for better control over fuel flow and pressure, ensuring optimal combustion and power delivery.

When upgrading fuel filters and pressure regulators, ensure compatibility with your engine and consider factors such as flow rates, filtration capabilities, and adjustment options to meet your specific needs.

Proper maintenance of fuel filters and regular monitoring of fuel pressure are essential to ensure the longevity and performance of your fuel system enhancements. Follow manufacturer recommendations for filter replacement intervals and pressure checks to avoid any potential fuel system issues.

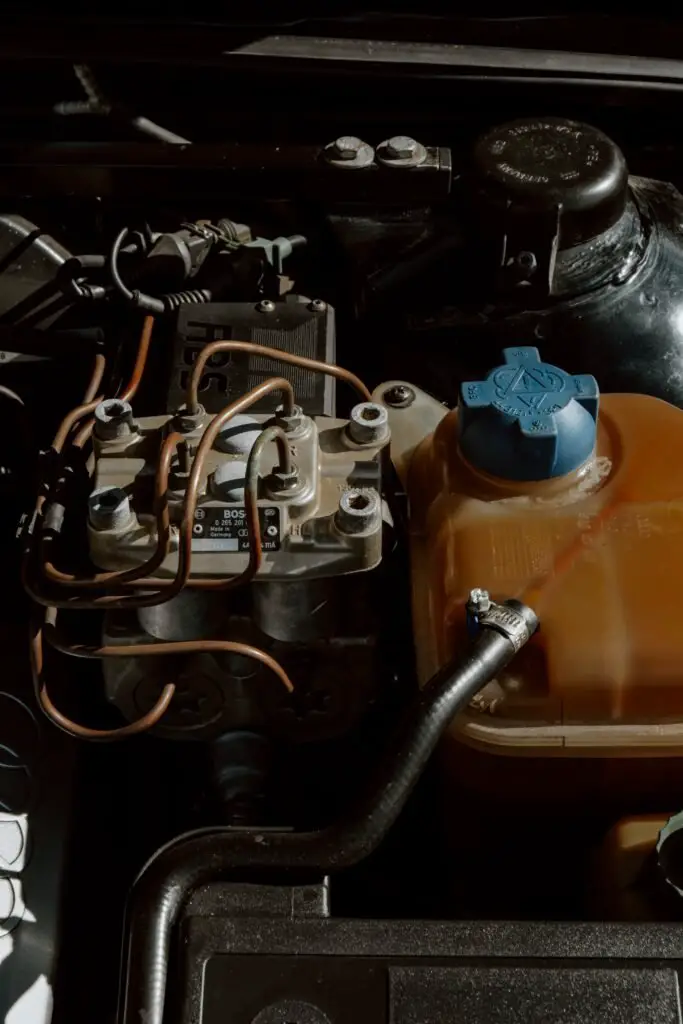

6. Ignition System Upgrades

6.1 Enhancing Ignition Performance

Upgrading the ignition system of your boat’s engine is a key performance modification that can significantly improve power, fuel efficiency, and overall engine performance.

The ignition system is responsible for delivering a high-energy spark to ignite the air-fuel mixture in the engine’s cylinders. By enhancing the ignition performance, you can achieve a more complete combustion process, resulting in improved power output and efficiency.

Upgraded ignition systems provide a stronger and more reliable spark, allowing for better ignition under various operating conditions. This results in improved throttle response, smoother idle, and reduced chances of misfires or incomplete combustion.

6.2 Types of Ignition Systems

There are several types of ignition systems available for boat engines, each offering different features and performance benefits.

Conventional ignition systems utilize a distributor, ignition coil, and spark plug wires to deliver the spark to each cylinder. While proven and reliable, conventional systems can sometimes suffer from energy losses and timing inaccuracies.

Distributorless ignition systems (DIS) eliminate the distributor and utilize individual ignition coils for each cylinder. This allows for precise control of ignition timing and better energy transfer, resulting in improved overall performance and efficiency.

Another option is direct ignition systems (DI), also known as coil-on-plug systems. DI systems place the ignition coil directly on top of each spark plug, eliminating the need for spark plug wires. This design provides the most efficient spark delivery and reduces energy losses, resulting in optimal combustion and power output.

6.3 Benefits of Upgrading Ignition Components

Upgrading ignition components can provide several benefits to enhance your boat’s performance and reliability.

One of the main advantages is improved spark energy. High-performance ignition coils produce a stronger spark, ensuring reliable ignition under various operating conditions. This leads to improved throttle response, smoother acceleration, and reduced chances of misfires or hesitation.

Upgraded ignition modules or control units can offer better control over ignition timing, allowing for precise adjustments to optimize power delivery and efficiency. Some advanced ignition systems include features such as multiple spark discharge or individual cylinder control, further enhancing combustion and performance.

Additionally, upgrading to high-performance spark plugs can further improve ignition performance. These plugs are designed to withstand higher temperatures and provide a more efficient spark, resulting in improved combustion and power.

When upgrading ignition components, it’s important to ensure compatibility with your engine and ignition system. Consult with an ignition system specialist or an experienced mechanic who can recommend the right components based on your specific engine and performance goals.

7. Cooling System Improvements

7.1 Effective Cooling for Better Performance

The cooling system is a vital component of any boat engine, and making improvements in this area can have significant benefits for overall performance and reliability.

Efficient cooling is essential to prevent overheating and maintain optimal operating temperatures. Upgrading the cooling system can help dissipate heat more effectively, allowing the engine to run cooler and avoid potential damage.

By ensuring effective cooling, you can also maintain consistent power output and prevent power loss due to heat-related performance limitations. This becomes especially important during extended periods of high-performance operation or hot weather conditions.

7.2 Upgrading Radiators and Heat Management

One of the main components of the cooling system is the radiator, which is responsible for dissipating heat from the engine coolant. Upgrading to a larger or more efficient radiator can enhance heat dissipation, allowing the engine to run cooler even under demanding conditions.

Additionally, improving heat management within the engine compartment can further aid in cooling. Upgrading heat shields, adding insulation, or installing heat-absorbing materials can help reduce heat soak and maintain lower temperatures, especially around critical engine components.

Consider the specific demands of your boat’s engine when selecting cooling system upgrades. If you engage in high-performance or racing applications, a high-capacity radiator or specialized cooling system may be necessary to handle the increased heat generated by additional power or prolonged periods of intense use.

7.3 Water Pump and Thermostat Considerations

The water pump plays a critical role in circulating coolant throughout the engine, aiding in the cooling process. Upgrading to a high-performance water pump can improve coolant flow, ensuring better heat transfer and more efficient cooling.

Additionally, the thermostat regulates the flow of coolant based on the engine’s operating temperature. Upgrading to a thermostat with a lower opening temperature can help maintain lower temperatures, especially during idle or low-speed operation.

When upgrading the water pump or thermostat, ensure compatibility with your engine’s specifications and cooling system layout. It’s also important to follow manufacturer recommendations regarding installation and maintenance to ensure optimal performance and reliability.

Proper maintenance of the cooling system, including regular coolant changes and inspections, is vital to prevent any cooling system issues. Keep an eye on coolant levels, hoses, and belts, and address any leaks or abnormalities promptly to avoid potential engine damage.

8. Camshaft and Cylinder Head Modifications

8.1 Enhancing Airflow with Camshaft Modifications

Modifying the camshaft and cylinder head of your boat’s engine can have a significant impact on airflow and power output.

The camshaft regulates the opening and closing of the engine’s valves, determining the timing and duration of the intake and exhaust cycles. Upgrading to a high-performance camshaft can optimize valve lift and duration, allowing for improved airflow into and out of the engine.

By increasing valve lift and duration, a performance camshaft can provide more air and fuel mixture to the combustion chambers, resulting in increased power and torque. This is especially beneficial at higher RPMs, where improved airflow becomes crucial for engine performance.

8.2 Cylinder Head Porting and Polishing

Cylinder head modifications, such as porting and polishing, further enhance airflow and combustion efficiency.

Porting involves reshaping and smoothing the intake and exhaust ports of the cylinder head. By removing any restrictions or irregularities in the port walls, porting improves the flow of air and fuel mixture into and out of the combustion chambers. This allows for better power output, throttle response, and overall engine efficiency.

Polishing refers to smoothing the surfaces of the intake and exhaust ports for better airflow. By reducing surface roughness, polishing minimizes turbulence and resistance, allowing air and fuel to flow more freely. This results in improved cylinder filling and combustion, translating to increased horsepower and torque.

Cylinder head modifications such as porting and polishing are typically performed by experienced engine builders or machine shops. It’s important to consult with professionals who have the necessary expertise and equipment to ensure proper modifications that suit your specific engine and performance goals.

8.3 Performance Valve Trains

Upgrading the valve train components, including valves, springs, and retainers, can further enhance engine performance and durability.

High-performance valves are typically made of stronger materials, such as stainless steel or titanium, to withstand higher temperatures and pressure. These valves offer improved flow characteristics and are less prone to deformation or failure under extreme conditions.

Upgraded valve springs ensure proper valve control and prevent valve float, allowing for higher engine RPMs without compromising valvetrain stability. Performance springs are designed with increased spring rates to handle the demands of modified engines or aggressive camshaft profiles.

Retainers and locks are also crucial components of the valve train. Upgraded retainers and locks provide better stability and can withstand higher forces, reducing the risk of valve train failure.

When upgrading valve train components, it’s crucial to ensure compatibility with your engine and camshaft specifications. Consult with an engine builder or a knowledgeable mechanic who can recommend the appropriate components based on your specific engine modifications and performance goals.

9. Turbocharging

9.1 Boosting Performance with Turbochargers

Turbocharging is a popular method of increasing power and torque in boat engines, providing significant performance gains without the need for substantial engine modifications.

A turbocharger utilizes exhaust gases to drive a turbine, which in turn compresses the incoming air before it enters the engine. By forcing more air into the combustion chambers, turbocharging increases the density of the air-fuel mixture, resulting in improved power output.

One of the main advantages of turbocharging is the potential for a significant increase in horsepower and torque. Turbocharged engines can produce substantially more power than naturally aspirated engines of the same size, allowing for better acceleration and higher top speeds.

Additionally, turbocharging can compensate for power loss at higher altitudes by providing increased air density, making it suitable for boating in mountainous or high-elevation areas.

9.2 Intercoolers and Wastegates

Intercoolers and wastegates are essential components of a turbocharging system that enhance performance and control the turbocharger’s operation.

Intercoolers, also known as charge air coolers, are used to reduce the temperature of the compressed air before it enters the engine. Cooler air is denser, allowing for a higher volume of air to be combusted, which leads to increased power output. Intercoolers effectively combat the heat generated by the turbocharging process, improving overall efficiency.

Wastegates, on the other hand, control the boost pressure generated by the turbocharger. They regulate the flow of exhaust gases to the turbine, controlling the speed at which the turbine rotates and the boost pressure produced. Proper wastegate tuning ensures optimal boost levels and prevents overboosting, which can cause engine damage.

When adding turbocharging to a boat engine, it’s crucial to ensure the turbocharger’s size and specifications match the engine’s requirements. Additionally, consult with an experienced engine builder or a knowledgeable mechanic to ensure proper installation and tuning of intercoolers and wastegates.

9.3 Pros and Cons of Turbocharging

Turbocharging offers several benefits for boat engines but also has some considerations that should be taken into account.

One of the main advantages is the significant increase in power and torque. Turbocharged engines provide a substantial boost in performance, allowing for improved acceleration, top speed, and towing capabilities. This can greatly enhance the overall boating experience, especially for those who enjoy watersports, fishing, or high-performance boating.

Turbocharging also offers the advantage of improved fuel efficiency. By utilizing exhaust gases to drive the turbine, turbochargers recover energy that would otherwise be wasted, making the engine more efficient. This can result in improved fuel economy, reducing operating costs and environmental impact.

However, there are also some considerations when it comes to turbocharging. Turbochargers introduce additional complexity to the engine, requiring proper maintenance and servicing to ensure long-term reliability. It’s important to follow manufacturer recommendations regarding oil changes, cooling system maintenance, and overall care of the turbocharging system.

Turbocharged engines can also produce additional heat, which needs to be managed effectively to prevent overheating and potential engine damage. Upgrading the cooling system and ensuring proper airflow through the engine compartment are important steps to avoid any heat-related issues.

Ultimately, turbocharging can be a rewarding performance modification for boat engines, but it’s crucial to consider the specific requirements of your boat and engine to ensure a successful and reliable installation.

10. Intake System Upgrades

10.1 Improving Air Intake Efficiency

Upgrading the intake system of your boat’s engine is an effective way to improve performance by enhancing the flow of air into the combustion chambers.

The intake system is responsible for delivering air to the engine, and any restrictions or inefficiencies can limit overall performance. Upgrading the intake system can help optimize airflow, resulting in improved power, throttle response, and fuel efficiency.

By increasing the efficiency of air intake, an upgraded intake system can deliver a greater volume of air to the combustion chambers. This allows for more efficient combustion, as the air-fuel mixture can be better optimized, resulting in increased power and torque.

10.2 Air Filters and Intake Manifolds

Two key components of the intake system that can be upgraded are air filters and intake manifolds.

Upgrading to a high-performance air filter allows for better airflow while effectively filtering out unwanted particles and contaminants. High-performance filters often use specialized materials and designs to maximize flow without sacrificing filtration efficiency. This ensures cleaner air reaches the engine, reducing the risk of engine damage and improving overall performance.

Intake manifolds are responsible for distributing the air from the intake system to each cylinder. Upgraded intake manifolds are designed to enhance airflow and minimize restrictions, leading to improved power and throttle response. Manifolds can be optimized for specific engine applications, such as high-performance or low-end torque, depending on your boating preferences.

When upgrading air filters and intake manifolds, it’s crucial to ensure compatibility with your engine and intake system layout. Consult with an intake system specialist or an experienced mechanic who can recommend the right components based on your specific engine specifications and performance goals.

10.3 Cold Air Intake Systems

Cold air intake systems are a popular upgrade for boat engines, providing additional performance benefits by delivering cooler air to the engine.

Cold air intakes typically feature a specially designed air filter and tubing that extends outside the engine compartment to draw in cooler, denser air from outside the boat. Cooler air is denser, resulting in a higher volume of oxygen available for combustion, which translates to increased power and torque.

The extended tubing of cold air intake systems also helps isolate the intake from heat generated by the engine, minimizing the chances of heat soak and preserving intake air temperature.

When selecting a cold air intake system, ensure that it is designed for your specific boat’s engine and intake configuration. Consider factors such as installation ease, water resistance, and compatibility with any other modifications or components in your intake system.

Proper installation and maintenance of cold air intake systems are essential to ensure optimal performance and reliability. Follow the manufacturer’s instructions regarding installation procedures and recommended filter cleaning or replacement intervals.

In conclusion, upgrading various aspects of your boat’s engine can provide significant performance improvements and enhance your boating experience. Whether you choose superchargers, engine tuning, exhaust systems, propeller upgrades, fuel system enhancements, ignition system upgrades, cooling system improvements, camshaft and cylinder head modifications, turbocharging, or intake system upgrades, it’s important to consider the specific requirements of your boat and engine. Consult with professionals who can provide guidance and recommendations tailored to your specific needs, ensuring that the upgrades are properly installed and optimized for maximum performance, reliability, and enjoyment on the water.