Keeping that diesel boat engine in shipshape condition is non-negotiable for any seafaring enthusiast. This wealth of knowledge, known as the “Ultimate Guide to Maintaining a Diesel Boat Engine,” is the resource you’ve been longing for, acting as your own personal lighthouse, guiding you through maintenance operations with ease and expertise. Get ready to elevate your understanding of diesel engine care, ensuring smoother operations, longer engine life, and uninterrupted sea adventures. Your diesel engine is the heart of your vessel, and this guide might just be the lifeline you need.

Understanding Diesel Boat Engines

Ahoy, there! You’re at sea, navigating the blue waters on your diesel-powered boat – life feels near perfect. To continue enjoying this bliss, understanding your boat’s diesel engine is vital. Without the engine, of course, your boat is a giant floating device going nowhere. Let’s dive into the nitty-gritty of diesel boat engines.

Importance of Diesel in Marine Engines

So, why is diesel fuel so important to your marine engine? Diesel engines are famously robust and reliable and particularly popular in the marine industry. They provide a stronger punch of power and are notably fuel-efficient due to their high-energy density. Hence, capacious diesel tanks equate to longer boating adventures! A risk of fire is also significantly lower – a necessity considering safety on the water.

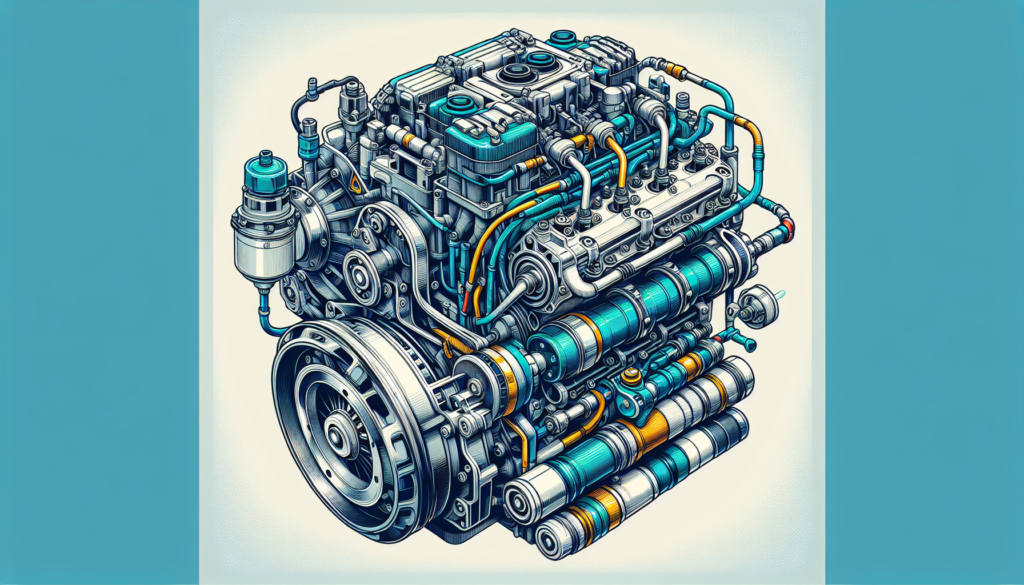

Understanding Basic Diesel Engine Components

Don’t worry; you’re not expected to be a mechanical engineer to understand your engine’s basics! At the heart of a diesel engine are its core components. The fuel injector sprays pressurized diesel into the combustion chamber, and the spark plugs ignite it. The energy thus produced thrusts the pistons, converting the linear action into a rotating one via the crankshaft – that’s the vroom you love!

Types of Diesel Boat Engines

Got your captain’s hat on? Good, because there are different types of diesel boat engines. Inboard diesel engines, a common type, sit within your boat, directly hooked to your boat’s propeller through a drive shaft. Then there are Outboard diesel engines – attached to the boat’s outside and easier to swap in and out. There are also Sterndrive engines, a mix of both – inboard power, outboard convenience.

Inspection of Diesel Boat Engines

Heard the sea adage “An ounce of prevention is worth a gallon of cure?” Regular inspection of your diesel boat engine can save you from many future headaches in the middle of the ocean.

Inspecting the Engine Regularly

Regularly inspecting your boat engine reduces the risk of unexpected component failures. Weekly checks when in regular use, and monthly when idle, should suffice. Look for outward signs of wear and tear and listen for unusual noises – a healthy engine usually purrs.

What to Look for During Engine-inspection

During inspections, check the clear latch of the sea strainers, the tightness of the hoses, and the state of the drive belts. Pay special attention to the engine oil – ensure it’s at the correct level and devoid of a milky color signaling water intrusion.

Importance of Professional Inspections

Even the sharpest eye may miss a future problem. Hence, periodic professional inspections are necessary. A skilled mechanic can help detect potential issues that may not be evident to the untrained eye and rectify them before it escalates further.

Regular Maintenance Practices

Just like your car or your body, your diesel boat engine needs regular maintenance. It’s the secret to a long, problem-free life on the waves.

Routine Oil Change

Firstly, the engine oil change. Like clockwork, every 100 hours of operation or at least once yearly. The oil’s primary function is to lubricate internal parts – with time the oil degrades and can lead to significant damage if not drained and replaced.

Replacement of Filters

The filters protect your engine from potential contaminants in air and fuel. Replace the fuel and oil filters at every oil change and the air filter once a year to safeguard your engine’s health.

Diesel Injection Maintenance

The diesel injection system is crucial to the engine’s operation. Care for it by using high-quality diesel to prevent gumming up the fuel system. This system needs professional inspections as it operates under high pressure.

Cleaning and Tightening of Connections

Lastly, clean all battery connections, tighten wiring harness connections, and inspect for any corrosion regularly. Check gaskets and clamps for tight fitting. These seemingly small things cumulatively make a huge difference in engine performance.

Understanding Common Diesel Engine Problems

Even the best-maintained diesel boat engine can face some common problems. But worry not, knowledge is power, and knowing what to expect keeps panic at bay.

Diesel Bugging in Fuel Tanks

Ever heard of diesel bug? Well, it’s not an insect, but a microbial growth in your fuel tank that feeds on diesel. These can clog your filters and damage the engine parts. Using biocide treatments in the fuel tank is an effective prevention method.

Overheating Problems

Overheating is a common engine issue often resulting from faulty cooling systems, blockage in the water intake, or low coolant levels. If the engine is heating up faster than usual, then it’s an overheating condition calling for immediate attention.

Exhaust Issues

Exhaust problems often point towards an issue with the exhaust manifold or head gasket. Black smoke in the exhaust is a common warning sign that should not be ignored.

Wear and Tear of Diesel Components

Many components like the drive belts, hoses, gaskets, and seals undergo regular wear and tear and need timely replacements. An irregular rattling noise often signals loose or worn-out parts.

Troubleshooting Diesel Engine Issues

One day, you might hear an odd knock, or there’s mysterious black smoke or an unexpected refusal to start. Don’t panic. Often, you can troubleshoot it yourself.

Interpreting Warning Signs

Understanding different warning signs is the first step towards effective troubleshooting. For instance, white exhaust smoke can imply water intrusion, whereas black smoke could mean an engine overload.

Identifying Common Symptoms of Failure

Unanticipated shutdowns, poor fuel efficiency, colored exhaust smoke, and abnormal vibrations are some of the common symptoms of diesel engine failures.

Tools Required for Troubleshooting

Having the appropriate troubleshooting toolkit helps you respond effectively. Some important tools you will need include a multimeter to check electrical connections, wrenches for bolts and screws, and oil filter pliers.

Dealing with Start-up Issues

The failure to start is a common diesel engine problem. It could be due to insufficient fuel, clogged fuel lines, or a degraded battery. Try to identify the underlying cause and address it specifically.

Repairing Diesel Boat Engines

While similar to a car engine, a boat engine operates differently and has unique demands. A few repair skills can come in handy.

Basic Repair Skills You Need

Some basic skills you could use include changing filters and engine oil, replacing drive belts, cleaning battery connections, and checking coolant levels. These tasks might sound complicated but trust me, with some patience and practice, you’ll master them!

Replacement of Broken Engine Parts

In case of major damages, you might need to replace parts. These can range from spark plugs and alternators to injection pumps and pistons. Always choose high-quality components for replacements to ensure durability.

Working with Professionals for Major Repairs

Some tasks are best left to professionals. Intricate repairs like valve adjustments, fuel injection pump issues, and repairing heat exchangers need a skilled mechanic’s touch. Always choose a marine engineer experienced in diesel engines for such repairs.

Winterizing a Diesel Boat Engine

If your boat rests idle during the colder months, winterizing is a must to avoid substantial damage. It involves preparing the engine for long-term storage to reduce the risk of coagulated engine oil and frozen water in the motor.

Understanding the Process

Winterizing is not as daunting as it sounds. It involves draining the engine oil, replacing it with fresh oil, applying a fogging solution to the engine, and draining the cooling system or filling it with antifreeze.

Preparing Your Engine For Winter

To prepare your boat’s diesel engine for winter, consider adding fuel stabilizers to the fuel tank and run the engine for a few minutes to circulate fresh oil. Remember to take care of essential engine components and fluids!

Storing Your Boat Properly For the Winter

Your boat’s storage place during winter also contributes to how well the engine is preserved. Ideally, keep it indoors, or under a sturdy waterproof cover. Store it in a slightly elevated position to avoid water accumulation.

Improving Diesel Engine Performance

Eager to squeeze out every ounce of your boat’s performance? With regular checks and a few adjustments, you can further improve engine power while ensuring longevity.

Optimizing Fuel Efficiency

A well-tuned engine burns fuel more efficiently, delivering better mileage and overall performance. Regular servicing, timely replacement of filters, and usage of quality diesel can enhance fuel efficiency.

Utilizing Coolant System

The coolant system helps maintain the engine’s optimum operating temperature. keep the coolant in good condition and ensure it’s at the appropriate level to prevent overheating and optimize performance.

Increasing Air Intake

More air in the combustion process equates to a more significant power boost. Regular cleaning of the air filter ensures optimal air intake and performance.

Balancing the Load

Overloading your boat can strain the engine leading to performance issues. Always maintain a good weight balance onboard for a smoother, faster ride.

Safety Precautions During Maintenance

Safety first! Even simple engine maintenance comes with certain risks and it is important you stay abreast of safety measures.

Proper Use of Tools

Always use the appropriate and well-maintained tools for any engine work. Improper or poor-quality tools can result in injuries and further damage to the engine.

Handling of Diesel Fuel

Diesel fuel requires careful handling as it is flammable and volatile. Store it in appropriate containers away from open flames, and avoid direct contact with skin or eyes.

Maintaining a Clean Engine Room

A cluttered engine room increases the risk of accidents and makes engine inspection and maintenance difficult. Keep the engine room clean, well-lit, and organized.

Establishing a Fire Safety Plan

Always keep fire extinguishers handy and follow a comprehensive fire safety plan. It should include regular checks of fire alarm systems and proper training for all aboard.

Reconditioning Old Diesel Engines

Finally, remember, old does not necessarily mean obsolete! With proper reconditioning, you can breathe new life into your older engines.

Benefits of Engine Reconditioning

Reconditioning not only improves your engine’s performance and reliability but can also extend its life and save you money by avoiding the cost of a new engine.

When to Consider Reconditioning

If your engine is frequently causing problems and your repair costs are mounting up, it may be time to consider reconditioning. It is also a smart choice if your engine is outdated and lacks modern features.

Cost Implication of Reconditioning

In the long run, reconditioning is less costly than buying a new engine, especially for robust diesel engines. However, it still involves costs related to labor, parts, and professional services.

In conclusion, to keep your diesel boat engine running smoothly, knowledge and timely maintenance are paramount. Understanding the intricacies of its operation, recognizing potential problems, and knowing when to use professional help will ensure you have many more memorable adventures at sea. And remember – keep your safety hat on, sailor!