Sailing over the horizon on your boat can be a dream come true until the engine starts heating up. “Understanding Boat Engine Cooling Systems” is your lifesaver here as it serves as a comprehensive guide to help you navigate the complex engineering behind boat engine cooling systems. This well-informed manual savvy you to troubleshoot peaks in temperature and offers valuable insights into the detailed mechanics of heat management in marine engines. So, gear up and prepare to take charge of your boat’s heart-throbbing machinery!

The Basics of Boat Engine Cooling Systems

Before we dive into the nitty-gritty of boat engine cooling systems, why don’t we establish some basics?

Definition of a Boat Engine Cooling System

A boat engine cooling system is a collection of components designed to regulate the internal temperature of the engine on a boat, whether it’s a speedboat, a fishing boat, or a yacht. These contraptions prevent the engine from overheating regardless of how hard the engine’s working. And just as the radiator ensures that your car engine runs smoothly without getting too hot, so does the cooling system bobbing about in your boat engine.

Importance of the cooling system in a boat engine

Even though ensuring the temperature remains at optimal levels might sound deceptively simple, this process is crucial for your boat engine’s performance and longevity. Overheating can lead to loss of power, poor fuel efficiency and the risk of severe engine damage. Therefore, ensuring the integrity of your engine cooling system is an essential aspect of boat maintenance.

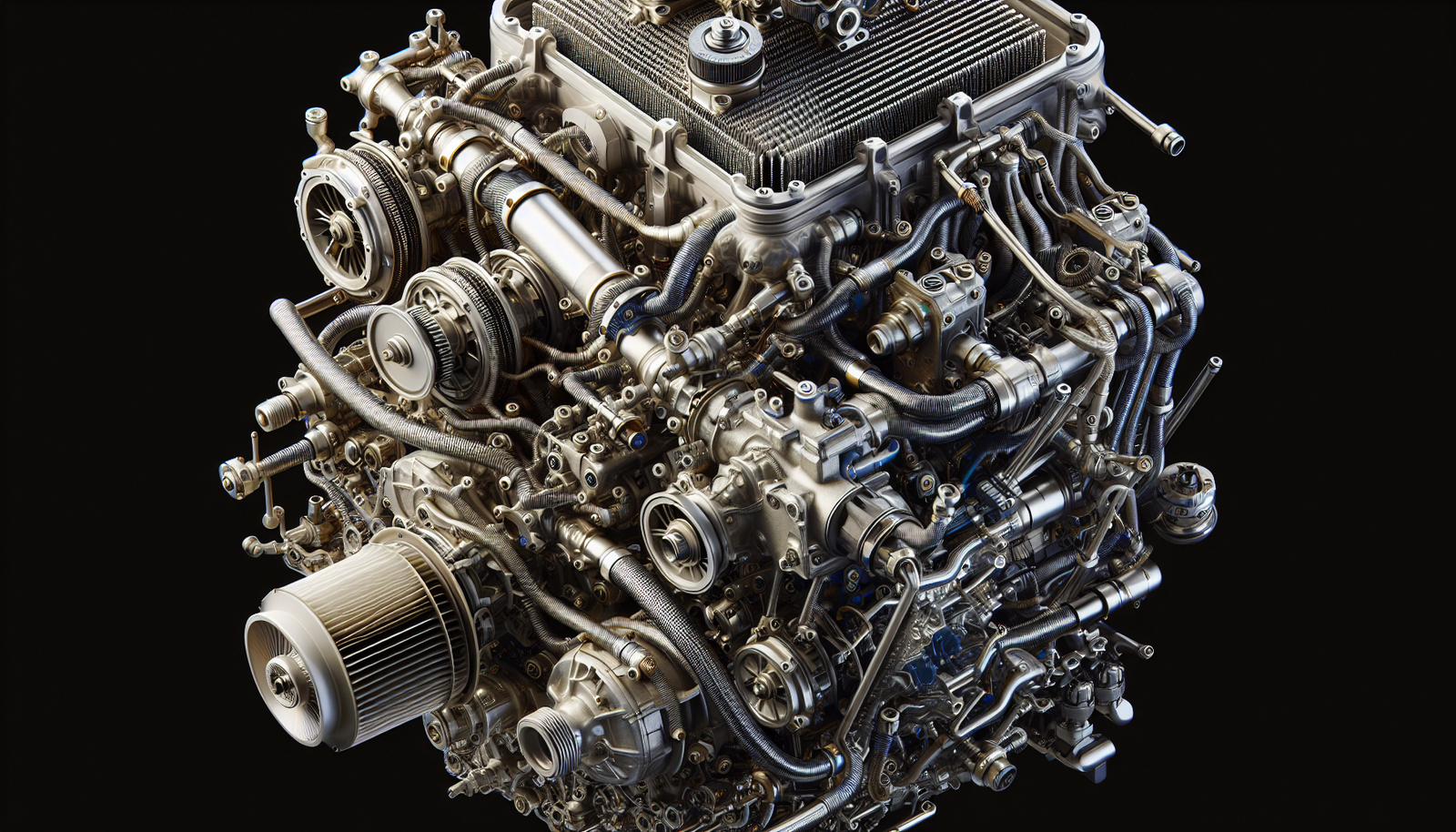

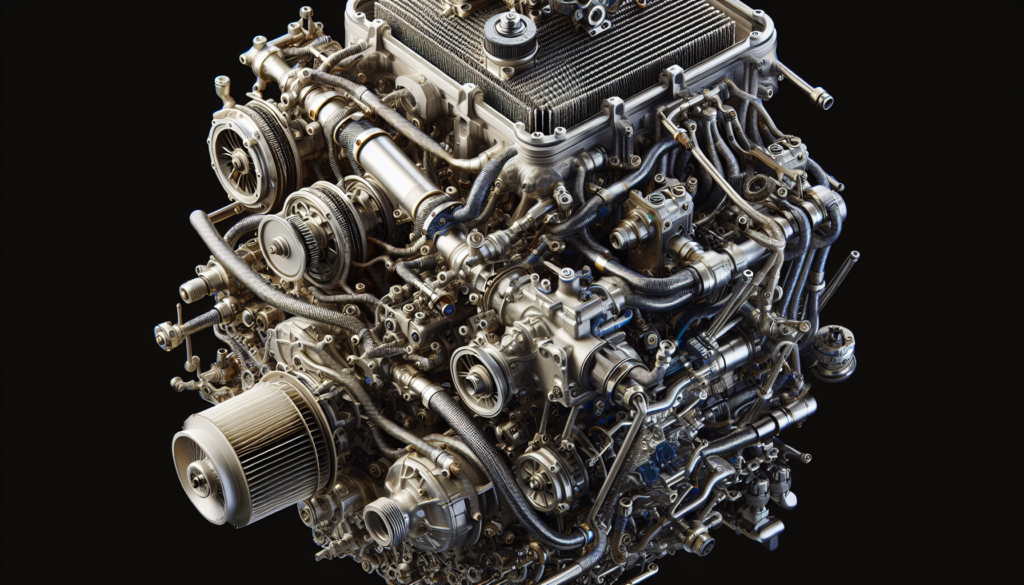

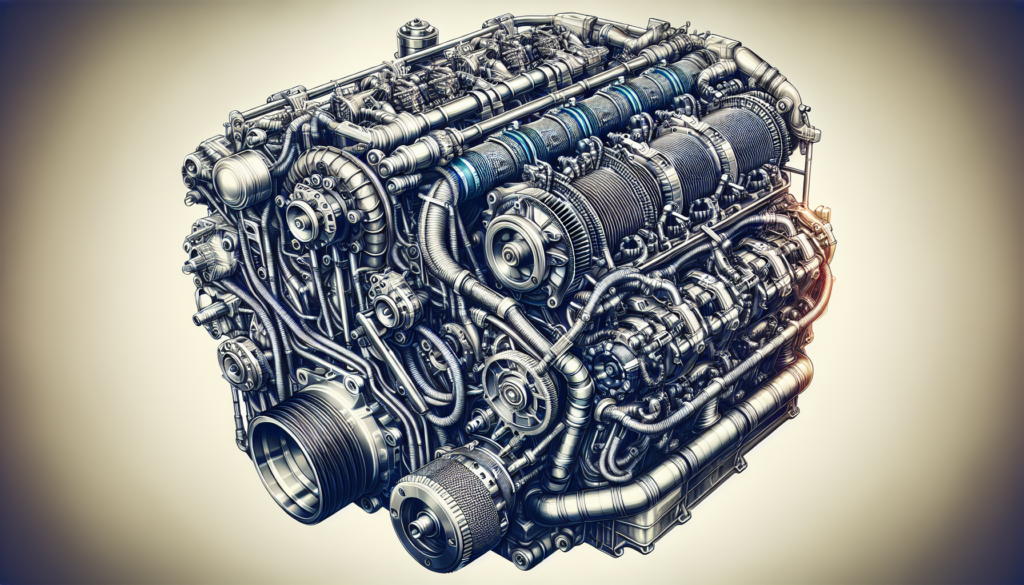

Primary components of a cooling system

The typical boat engine cooling system consists of a few vital components, including a water pump, a heat exchanger, and a thermostat. Some systems use direct contact with seawater for cooling (referred to as raw water cooling systems), whereas others incorporate a coolant like in your car (referred to as closed or fresh-water cooling systems).

Types of Boat Engine Cooling Systems

While boat engine cooling systems might seem quite straightforward, there are actually quite a few types out there. Let’s take a closer look at some of them.

Raw Water Cooling System

The most traditional of the cooling systems, the raw water cooling system, uses water from around the boat — be it seawater or freshwater — which gets directly pumped into the engine for cooling purposes. It is simple, cost-effective, and requires minimal maintenance, but seawater can lead to corrosion issues over time.

Fresh Water or Closed Cooling System

This system operates most similarly to automotive cooling systems. Here, a mixture of water and coolant circulates through your boat engine, absorbing its heat, which is then dissipated into seawater via a heat exchanger. This system offers more satisfactory protection against corrosion but can be more complex and requires the use of high-quality coolant.

Keel Cooling System

Keel cooling systems employ a series of pipes attached to the boat’s hull to dissipate engine heat directly into the water without it ever passing through the engine. These systems are traditionally used for smaller, slower-moving boats and provide an efficient, albeit somewhat bulky, cooling solution.

Exhaust Manifold Cooling System

In an exhaust manifold cooling system, water is introduced into the exhaust to cool the exhaust gases and reduce the temperature of the exhaust system. This reduces the risk of fire and extends the durability of the exhaust system components.

The Working of a Raw Water Cooling System

Understanding how a raw water cooling system functions could save you from a headache down the line. So, let’s break it down.

Water intake process

In a raw water cooling system, water is generally drawn into the system through the water intake on the bottom of the boat. This water is then directed to the water pump and sent to the engine.

Functioning of the heat exchanger

The heat exchanger acts as a middle ground. It’s here that the engine’s heat is transferred into the cooler seawater, which eventually gets expelled out with the exhaust gas.

Exhaust process

Finally, the now heated water is led out of the engine, typically through the exhaust system, expelling not only engine exhaust but also the heat from the engine.

The Operation of a Fresh Water or Closed Cooling System

Like the raw water variant, understanding the closed cooling system’s operations could help troubleshoot any potential issues. Here’s the step-by-step process.

Water-Coolant mixture preparation

The system commences with filling the engine with a mixture of water and antifreeze coolant. This concoction acts as a heat absorber within the engine.

Circulation of coolant concoction

The coolant mixture is then circulated through the engine by a water pump, where it subsides the heat being generated by engine components. As this mixture becomes warm, it then flows into the heat exchanger.

Control of temperature using a thermostat

The thermostat comes into play here. It controls the flow of coolant so that the engine can reach and maintain its optimal operating temperature.

Role of the heat exchanger

In the heat exchanger, the warmth from the coolant is extracted by surrounding seawater, which, much like in the raw water system, is typically discarded through the exhaust system.

Understanding a Keel Cooling System

For those with smaller, slower-moving vessels, the keel cooling system is an alternative worth considering.

Arrangement of pipes

In the keel cooling system, external pipes attached to the boat’s hull are filled with coolant, which absorbs the heat from the engine as it circulates.

Role of the sea or river water

The external placement of these pipes allows the sea or river water to dissipate the heat from the coolant without ever entering the boat engine, providing direct cooling to the engine.

Temperature control mechanism

A thermostat is also used in this system to control the coolant’s flow, ensuring the engine gets to its ideal operating temperature and stays there.

The Functioning of an Exhaust Manifold Cooling System

This system functions pretty differently from the previous two. Its approach focuses on keeping the exhaust system cool, which indirectly keeps the engine from overheating.

The role of the exhaust manifold

The exhaust manifold’s main task is to collect and route the exhaust gas out of the engine. However, this process generates a significant amount of heat that needs to be managed.

The purpose of cooling the manifold

By cooling the exhaust manifold, we reduce the overall temperature of the exhaust system. This limits the risk of fire – given that exhaust temperatures can reach dangerous levels – and prevents excessive heat from spreading to other engine components.

The process of cooling the manifold

With an exhaust manifold cooling system, water gets introduced post combustion process. Once the exhaust fumes pass through the manifold, the water is used to cool down the exhaust gases, reducing overall temperatures before the gases get expelled from the boat.

Maintenance of Boat Engine Cooling Systems

Boat engine cooling system maintenance may sound daunting but trust me, it’s crucial to the longevity and performance of your beloved vessel.

Periodic checks and servicing

Regular inspection is the first step in maintaining the health of your cooling system. This involves checks for leaks, corrosion, buildup, and broken components.

Replacement of damaged parts

Over time, components like hoses, clamps, seals or the water pump might wear down or break. Replacing these promptly will save you from future damage or costly repairs.

Regular cleaning of the systems

Over time, particularly in raw water and exhaust manifold systems, buildup can occur within pipes and components. Regular cleaning can prevent clogs and ensure efficient operation.

Importance of using high-quality coolant

For closed cooling systems, using high-quality coolant is vital. It helps prevent internal corrosion and ensures maximum heat absorption.

Common Problems with Boat Engine Cooling Systems

Unfortunately, problems with cooling systems are an inevitable part of boat ownership. Let’s familiarise ourselves with some of the common diagnoses.

Overheating

The most common sign of trouble in a cooling system is overheating. This typically indicates a lack of water flow, possible culprits include a malfunctioning water pump or clogged lines.

Leakage of coolant

Leaks can occur in any of the system’s components but are most common around hoses or seals. Look out for visible coolant traces or low coolant levels.

Clogging and corrosion issues

Seawater especially can lead to the accumulation of debris or salt within your system over time. This buildup can result in clogging or even corrosion down the line.

Failure of the thermostat

A malfunctioning thermostat can lead to overheating or low operating temperature, affecting the efficiency and performance of your boat.

Troubleshooting Boat Engine Cooling Systems

If you suspect there’s a problem with your cooling system, here are some DIY diagnostics you can undertake before calling for professional help.

Diagnosing overheating problems

Start checking from the water inlet for any blockages or leaks, then proceed through the system, checking the working of the pump, the thermostat, and the lines for proper flow and condition.

Locating coolant leaks

Look out for any signs of leaks along your hoses, clamps or seals. Check coolant levels and pressure within the system to further narrow down the issue.

Identifying and resolving clogs and corrosion

Systematic examination of each component will help spot any clogs or potential corrosion. Regular cleaning and use of corrosion inhibitors can proactively tackle these issues.

Checking and replacing a faulty thermostat

A telltale sign of a faulty thermostat is if your engine is running cooler than normal, or overheating unexpectedly. Replacing the thermostat is typically straightforward, but to err on the side of caution, consider having a professional do it.

Summary of Boat Engine Cooling Systems

Recap of types and functions of cooling systems

Well, there you have it, all you need to know about boat engine cooling systems! Whether it’s the simplicity of a raw water system, the anti-corrosive nature of the closed cooling system, the direct approach of a keel cooling system, or the safe exhaust manifold cooling system, each has its unique appeal and mode of operation.

Importance of regular maintenance

Just remember, no matter your boat engine cooling system’s type, regular maintenance is key to cruising bliss. Whether it’s regular inspections, timely replacements, vigilant cleaning, or quality coolant use, your vessel’s performance and longevity are in your hands.

Common issues and troubleshooting strategies

Facing issues with overheating, leaks, clogs, or thermostat failures may feel like a dampener, but don’t fret. Familiarize yourself with these common issues and their troubleshooting strategies will act as your first line of defense against them.

In conclusion, understanding the ins and outs of your boat’s engine cooling system will ensure you get the most out of your boat engine, ensuring smooth and joyful sailing. So, here’s to understanding, maintaining, and problem-solving all things boat engine cooling systems! Bon Voyage!