A well-maintained boat engine isn’t just about efficient sailing, it’s about safety. In the following article, you’ll find detailed steps on how to meticulously inspect your boat engine for corrosion. Being on the lookout for any signs of rust and overall engine wear and tear can help prolong the life of your marine investment and ensure many more sun-drenched days on the open water. So ready your tools and let’s get started on safeguarding your boat engine from the erosive effects of corrosion.

The Importance of Regular Boat Engine Inspections

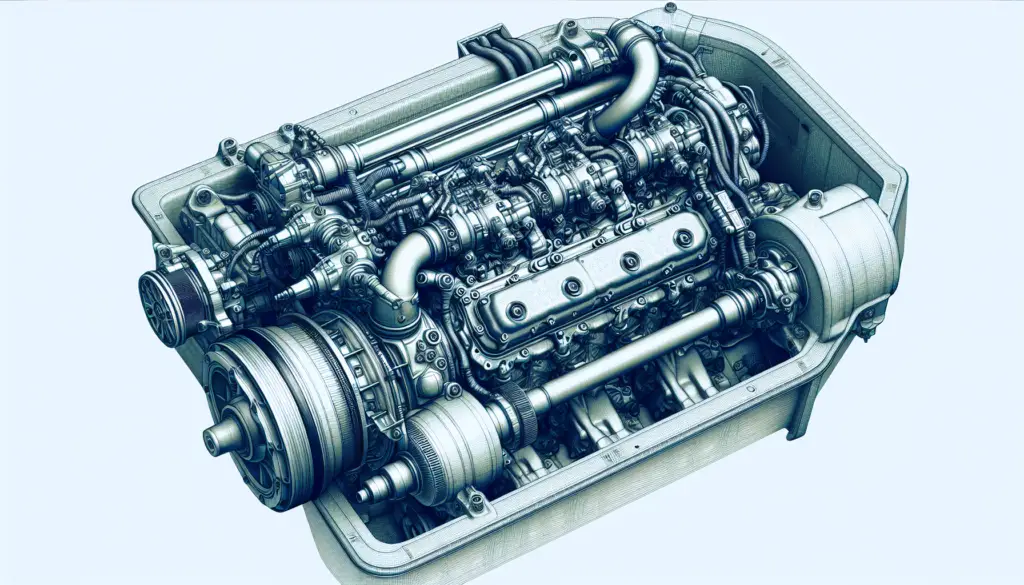

Boat engine inspections are an integral part of keeping your beloved vessel in tip-top shape. Regular check-ups ensure that all parts are functioning correctly, minimizing the risk of unexpected breakdowns. Your boat’s engine is like the heart of the vessel, and any issue with it could leave you stranded in the middle of a water body.

Understanding the need for routine inspection

Regular inspections might seem like a bit of a hassle, but they play a huge role in extending the lifespan of your engine and keeping it in good working condition. These check-ups help in early detection of potential problems, giving you ample time to address them before they escalate into costly issues. They also provide an opportunity to replace worn-out parts, enhancing your boat’s overall efficiency and safety.

Implications of neglecting regular inspection

In contrast, neglecting regular inspections can have dire consequences. Small issues that would have otherwise been detected in a routine check-up might escalate into serious problems, leading to a dramatical reduction in engine performance. In turn, this can cause a ripple effect on other engine components, leading to their premature wear and tear.

How corrosion impacts the performance and lifespan of a boat engine

-corrosion is one of the leading causes of engine damage in boats. It can deteriorate metal parts, compromise the performance of the engine, and, potentially, end its lifespan prematurely. Regular inspections are crucial in catching early signs of corrosion and taking appropriate measures to curb its progress.

Understanding Engine Corrosion

Corrosion in boat engines can be a stealthy assailant, gradually causing damage before you even notice its presence. It’s fundamental to understand this phenomenon to prevent and deal with it effectively.

What is engine corrosion

Simply put, engine corrosion is the gradual destruction of metal parts due to chemical reactions. In the marine environment, these reactions often involve salt, leading to what’s better known as saltwater corrosion.

Factors leading to engine corrosion

Various factors can lead to engine corrosion, including high humidity, fluctuating temperatures, accumulation of dirt and grime, and exposure to corrosive elements such as salt and water.

Types of corrosion commonly found in boat engines

Corrosion in marine engines generally manifests in two types: electrolytic and galvanic corrosion. Electrolytic corrosion typically occurs when electricity passes through metal parts, while galvanic corrosion is a result of metal-to-metal contact in the presence of an electrolyte (usually saltwater).

The rate of corrosion in different water types (freshwater vs saltwater)

Traditionally, many boaters believe that saltwater is more corrosive than freshwater due to its salinity. Although there is some truth to this, it’s worth noting that freshwater can also be a significant corrosive agent, especially if it’s stagnant or polluted.

Preparing for the Inspection

Before embarking on a boat engine inspection, several factors should be taken into account to ensure it’s done safely and effectively.

Safety measures to take before inspection

Regardless of your familiarity with your boat engine, always prioritize safety. Wear protective clothing, including gloves and goggles. Be sure to disconnect the battery before starting the inspection, and ensure that the engine is off and cool.

Tools and materials needed for inspection

Doing an engine inspection requires an assortment of tools such as a flashlight for illuminating dark areas, inspection mirrors for hard-to-reach spots, and a digital camera for documenting your findings. Engine movement is aided using a wrench while a clipboard and writing material is essential for recording your observations.

Proper boat engine cleaning

Before starting the inspection, your engine should be clean. A clean engine makes it easier to spot signs of corrosion and other potential issues. A mix of a degreaser and warm water is generally sufficient for this task.

Inspecting External Engine Parts

Inspecting the engine’s exterior is a fundamental part of an engine inspection process.

Procedure for inspecting the engine block and cylinders

Begin by inspecting the engine block and cylinders for any signs of corrosion or damage. Look for color changes, cracks or any signs of fluid leakage. Note that damaged blocks and cylinders can often lead to decreased engine performance and, in severe cases, complete engine failure.

Checking the fuel lines and connections

Moving on, inspect the fuel lines and connections. Ensure that they’re properly fastened and look out for signs of wear and tear or loose fittings. Leaking fuel can lead to corrosion as well as heighten the risk of fires.

Assessing the condition of the exhaust manifold and risers

Finish the exterior check with the exhaust manifold and risers. These components are prone to corrosion due to their exposure to exhaust fumes, and as such, any early signs of corrosion or damage should not be ignored.

Inspecting Internal Engine Parts

Internal engine parts are just as important for your boat’s overall performance.

Procedure for inspecting pistons and valves

Look out for any signs of corrosion on the pistons and valves. A buildup of deposits could signify oil leaks and the possible commencement of corrosion.

Checking the internal cooling system

The internal cooling system warrants thorough inspection. Look out for any signs of coolant leaks. If coolant leaks inside the engine, it could lead to internal corrosion and pose major threats to the engine’s performance.

Assessing the condition of the crankshaft and camshaft

Finally, check the condition of the crankshaft and camshaft. These parts are crucial in controlling the engine’s output, and any damage or corrosion detected should be addressed immediately.

Inspecting the Boat’s Cooling System

The cooling system plays a pivotal role in the overall engine health.

The role of the cooling system in engine corrosion

The cooling system circulates coolant throughout the engine, keeping it from overheating. Leaky coolants are one of the prime sources of internal engine corrosion, making the cooling system a major player in the corrosion scenario.

Checking for corrosive wear in the heat exchanger

Inspect the heat exchanger for any signs of corrosive wear or blockages. Remember, a mal-functioning heat exchanger directly impacts the efficiency of the cooling system.

Assessing the condition of the water pump and its impellers

Move on to the water pump and its impellers. Pay attention to details and look carefully for any signs of corrosion, pitting or wear.

Identifying Signs of Corrosion

Identifying the early signs of corrosion is key to reducing the severity of engine damage.

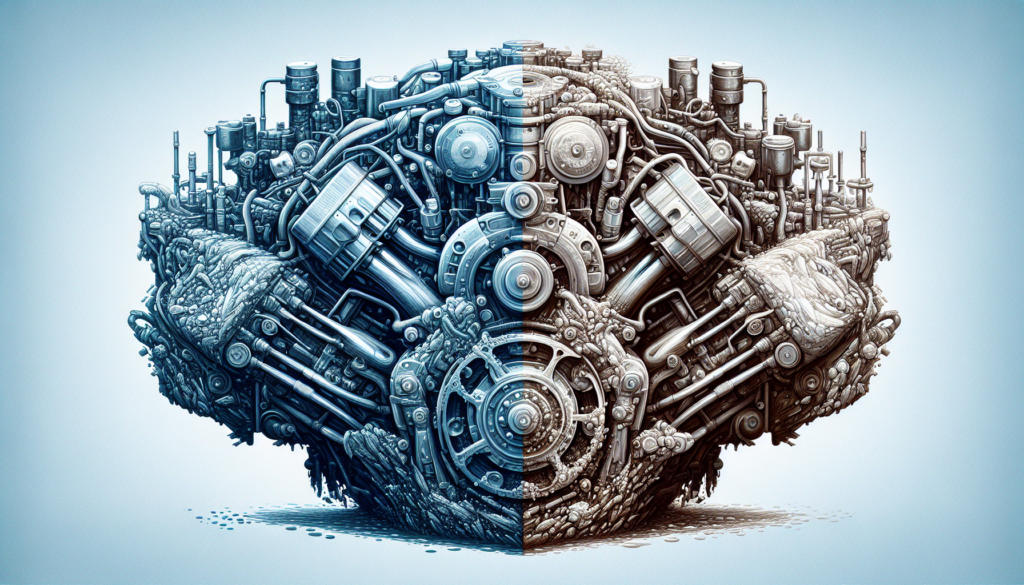

Typical signs of corrosion in boat engines

Typical signs of corrosion include discoloration, pitted surfaces, and flaking or cracked paint. In severe cases, corrosion sites might even develop holes.

Distinguishing between surface corrosion and severe corrosion

Surface corrosion is often characterized by surface level discoloration and is generally, not a threat to the engine if treated it in time. Conversely, severe corrosion penetrates the metal, causing structural damage and must be addressed immediately to prevent catastrophic failure.

Documenting the Inspection Findings

Examining and identifying issues is the first step; the next is documentation.

Recording the condition of each engine part

After inspection, record the condition of each engine part. This helps keep track of the engine’s health, making future inspections much more straightforward.

Photographing areas of concern for future reference

Take photographs of areas of concern. This visual documentation can provide a valuable reference for future inspections or consultation with a professional mechanic.

Establishing a schedule for future inspections based on findings

Based on the findings, establish a schedule for future inspections. More frequent checks may be necessary if high levels of corrosion were identified.

Addressing the Corrosion Issues

Once corrosion signs have been identified and documented, the next step is to address them.

Determining when professional repair is needed

Minor corrosion can often be handled with home remedies, but for more severe cases, it would be wise to seek professional help.

Steps for addressing minor surface corrosion

For minor corrosion, removing it with sandpaper and applying anti-corrosive paint is often sufficient.

Need for replacement of severely corroded parts

In contrast, severe corrosion often necessitates part replacement. Prolonging the usage of severely corroded parts can put the entire engine at risk.

Preventing Future Corrosion

Prevention is always better than cure, and in the case of engine corrosion, this rings especially true.

Routine cleaning and maintenance practices

Establish a routine for cleaning and maintaining your engine. This can significantly reduce the risk of corrosion.

Effective corrosion inhibitors and how to apply them

Using corrosion inhibitors is another powerful preventive measure. These chemicals form a protective layer over metal surfaces, slowing down the rate of corrosion.

The role of proper storage in preventing corrosion

Finally, proper storage plays a pivotal role in preventing corrosion. Minimize your boat’s exposure to water and humidity when not in use. A dry, well-ventilated storage area can do wonders in your fight against corrosion.

Taking care of your boat is a responsibility that should not be taken lightly. Regular engine inspections and preventive practices can go a long way in safeguarding your on-water enjoyment. Remember, in the art of boat maintenance, you are the artist, the boat is your canvas, and the engine is your masterpiece.