As a boat owner, keeping your vessel in shipshape condition is vital to your maritime adventures. This article, “Essential Boat Engine Maintenance Tips Every Owner Should Know”, is just what you need to make sure your vessel doesn’t leave you stranded mid-voyage. We’ll share expert advice on ways to properly care for your boat engine, from routine checks to important steps in preventative maintenance. Understanding these key tips can help ensure a long and reliable engine lifespan, saving you potential headaches and unexpected repair costs down the line. So roll up your sleeves and let’s get that engine humming smoothly for your next sea escapade.

Understanding the Importance of Boat Engine Maintenance

Boating is not just about fascination and thrill. It also involves keeping your boat and its engine in the best shape possible. This is where the importance of boat engine maintenance comes into play. It’s not just a simple practice but a crucial one that every owner must pay heed to.

Safety concerns tied to lack of maintenance

Boat engine maintenance is a key safety concern. Your boat’s engine is critical to operating your boat, and if not maintained effectively, it might cause serious safety issues. For instance, an ill-maintained engine can stall while you’re on the water or, worse, cause a fire. Regular inspections and tune-ups can prevent these costly and even life-threatening complications, thus ensuring a secure sailing experience.

Optimizing the performance of the boat

Regular boat engine maintenance is paramount to the boat’s overall performance. Just like taking care of your car ensures a smoother ride, maintaining your boat engine guarantees optimum performance on the water. A well-maintained engine will run smoothly, burn fuel efficiently, and respond readily to throttle adjustments, making every voyage enjoyable and worthwhile.

Preventing costly engine repairs and replacements

Due to the harsh maritime environment, boat engines are naturally susceptible to wear and tear. Nevertheless, regular upkeep can prevent or at the very least, delay significant engine repairs and replacements. Spotting damage early can save you costly repairs down the line, keeping your engine at peak performance and your wallet intact.

Ensuring the durability and longevity of the engine

An engine is to a boat what a heart is to a body. Its wide-ranging role can’t be overlooked. To keep your engine running efficiently and extend its lifespan, timely and regular check-ups are necessary. Servicing your engine seasonally or annually, as per use, supports it to last longer and saves you from unnecessary premature replacements.

Acquiring Basic Knowledge of the Boat Engine Parts

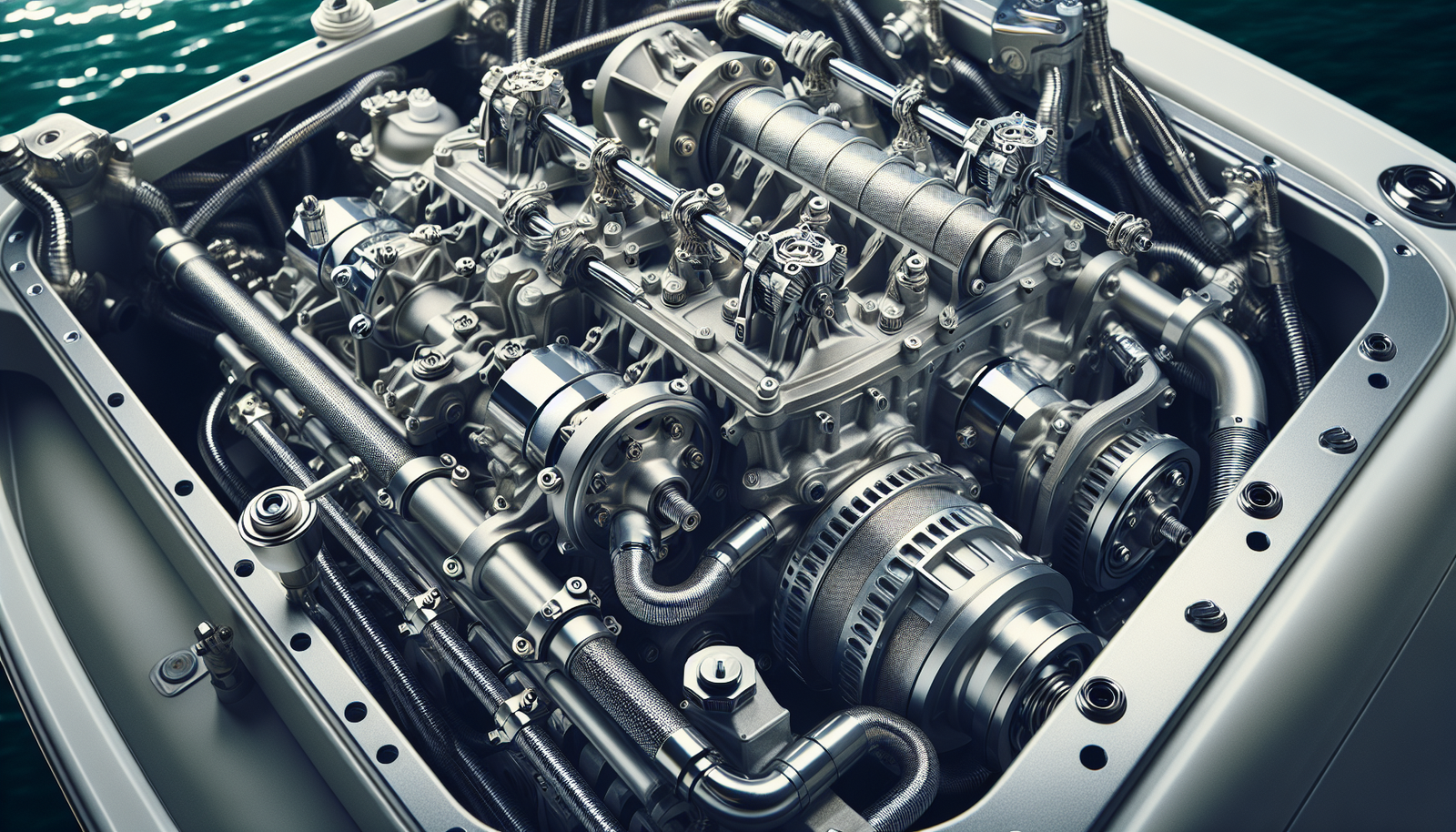

It’s critical to understand the basic inner workings of your boat before developing a solid maintenance routine. Let’s take a look at the major parts of a boat engine.

Learning about the major engine parts

Thiniking about the parts that make up a boat engine, you’ve got the propulsion system, fuel system, cooling system, and exhaust system, to name a few. Each aspect is integral to the overall functionality of your vessel and requires different maintenance procedures.

Function and maintenance of each engine part

Learning about each part can help you appreciate its role in the overall performance and understand the specific maintenance it requires. For example, the propulsion system turns the power of your engine into motion. Keeping the propulsion system well-lubricated is key to maintaining its functionality. On the other hand, the cooling system prevents overheating and needs to be checked for leaks and coolant levels regularly.

Regularly Checking the Boat’s Engine Oil

Just like with your car, maintaining the right level and quality of engine oil is a crucial part of boat engine maintenance.

Identifying appropriate oil levels

Most boat engines have an oil dipstick to check the oil level, similar to cars. The oil level should be between the two marks on the dipstick. If it’s below the lower marking, you’ll need to add more oil.

Choosing the right type of engine oil

The type of oil used plays a transformative role in extending the life of your boat’s engine. Selecting the right engine oil depends on several factors, including the boat’s engine type, its age, and your boating environment. Adhering to your engine manufacturer’s oil specifications is always the best way to go.

Frequency and timing of oil changes

On average, an oil change every 50 to 100 operating hours is recommended, but it’s best to follow your manufacturer’s advice on this. Stick to a regular schedule for oil changes to avoid the build-up of dirt and contaminants.

Maintaining the Fuel System

Your boat’s fuel system is another critical component that deserves proper care.

Ensuring clean and adequate fuel

A common problem with boat engines is fuel contamination, often by debris and water. Periodically testing the fuel quality and maintaining an adequate fuel level can help prevent such issues. Filling the tank can also avoid condensation.

Checking and replacing fuel filters

Fuel filters prevent impurities in the fuel from reaching the engine. Over time, these filters may get clogged and will need replacing. Regular inspection of your fuel system’s filters is thus paramount to maintaining your vessel’s healthy functioning.

Managing fuel additives and stabilizers

Fuel additives can enhance power, reduce emissions, and help fight the potential negative effects of ethanol in fuel. Fuel stabilizers, on the other hand, are fantastic for winter storage as they prevent fuel from going stale during long periods of non-use.

Inspecting and Cleaning the Engine’s Cooling System

The cooling system is a critical part of preventing your boat’s engine from overheating.

Understanding the function of cooling systems

A cooling system circulates coolant — generally a mixture of water and antifreeze — around the engine to absorb heat. The hot coolant then passes through a heat exchanger and goes back to the engine, maintaining an optimal temperature.

Monitoring the efficiency of the coolant

Boat engines rely on coolant to avoid overheating. Regularly checking your coolant level and topping it up when necessary is crucial to engine performance and longevity.

Timely replacement of the coolant

Like engine oil, coolant also deteriorates over time and will eventually need replacing. A general rule is to change your coolant every 2-3 years, although individual engine requirements may vary.

Maintaining the Propeller and Drive Belts

The propeller and drive belts play a key role in converting engine power into movement.

Routine inspection of the propeller

On a regular basis, especially after journeys, check your propeller for obvious damage. Even minor dents can lead to significantly reduced performance, increased fuel consumption, and potential damage to the transmission.

Proper cleaning and lubrication of propellers

Keeping your propeller clean is essential, as weed and marine growth can reduce its effectiveness. It also needs to be lubricated regularly to avoid it getting stuck on the propeller shaft.

Checking for drive belt tension and wear

Drive belts regulate many components of the engine, from water pumps to alternators. Over time, they can lose tension or wear out and may need fixing or replacing. Regular inspection ensures these essential items continue functioning optimally.

Checking the Battery and Electrical Systems

A healthy battery and electrical system are key to starting your engine and keeping your electronics running.

Maintaining battery charge

Batteries can lose charge over time, especially during periods of non-use. Regular charging ensures your boat starts when you need it to, and also prolongs the life of the battery.

Annual battery replacement

Depending on usage and maintenance, a marine battery typically lasts 2-4 years. However, proactive annual checks will ensure the battery is in good shape and help you avoid unfortunate surprises.

Inspecting wiring and circuit breakers

Regular checks of your boat’s wiring and circuit breakers are important. Damaged wires or tripped breakers can cause havoc on your electrics, so repair any faults as soon as they’re detected.

Exhaust Manifold and Risers Inspection

The exhaust manifold and risers are critical parts of the engine’s exhaust system that require regular checks.

Understanding their functions and problems

The exhaust manifold collects the exhaust gases from the engine cylinders, while risers prevent seawater from entering the engine. They both regularly come into contact with corrosive saltwater, which can potentially cause damage and leaks over time.

Recognizing signs of issues

Look out for signs of rust, corrosion, leaks, or warping on the risers and manifold. White salt deposits are a telltale sign of a leak that needs immediate action.

Repair and replacement of manifold and risers

Depending on the severity of the damage and the material from which they’re crafted, exhausted manifolds and risers often need repairing or replacing after 5-10 years of use.

Regularly Cleaning and Painting the Engine

Regular cleaning and painting can improve both the performance and the aesthetics of your engine.

Importance of keeping the engine clean

Not only does a clean engine look good, but it also helps you detect any leaks, corrosion, or other potential issues that could affect its performance.

Choosing the correct paint for the engine

When it comes to painting your engine, using the right kind of paint matters. Marine engine paint is specially designed to cope with the harsh marine environment and resist the high temperatures commonly found around engines.

Proper techniques for painting the engine

Before painting, you should clean the engine thoroughly and remove any old paint with a wire brush. After that, use masking tape to protect areas you don’t want to paint. Apply a primer first, then follow up with two or three fines coats of paint, allowing each one to dry in between.

Winterizing the Boat Engine

Properly winterizing your boat engine is a key part of ensuring it fires up trouble-free when it’s time to hit the water again in spring.

Understanding the process of winterization

Winterization refers to preparing your boat’s engine for storage during colder months. This system entails numerous steps that help protect your engine from potential cold weather damage.

Steps to adequately winterize the boat engine

Efficient winterizing includes thoroughly cleaning the engine, changing the oil, draining the coolant and replacing it with antifreeze, fogging the engine with a rust inhibitor, refilling the fuel tank, and disconnecting the battery.

Maintaining the engine during off-season storage

Even though your boat isn’t being used, maintenance during winter storage is crucial. Battery charges, visual checks of the engine bay, and running a heater, dehumidifier, or desiccants can aid in avoiding unpleasant surprises when you’re ready to get back on the water.

From its propeller to its engine block, each part of your boat requires regular maintenance to assure smooth sailing. Through regular checks, scheduled servicing, and minor repairs, you can prevent significant problems, ensure safety, and enhance the lifespan of your boat. Happy boating!

[…] for corrosion. Being on the lookout for any signs of rust and overall engine wear and tear can help prolong the life of your marine investment and ensure many more sun-drenched days on the open water. So ready your tools and let’s get […]

[…] the function and importance of boat engine belts and hoses is fundamental in boat maintenance. These components may seem minor in the grand scheme of an […]

[…] Regular maintenance is key to a healthy boat engine. It can be as basic as changing oil and filters, cleaning spark plugs, inspecting belts and hoses, and checking coolant levels. […]