If you’re a boat owner or enthusiast, you know that the key to a smooth and enjoyable experience on the water lies in a well-tuned engine. Whether you’re a seasoned sailor or a novice captain, understanding the best practices for boat engine tuning is essential for maintaining optimal performance and prolonging the life of your vessel. In this article, we will explore some expert tips and tricks to help you navigate through the world of boat engine tuning with confidence and ease. So, grab your captain’s hat and let’s set sail on this exciting journey towards peak engine performance!

Choosing the Right Tools and Equipment

When it comes to tuning your boat engine, having the right tools and equipment is essential. Not only will this make the process smoother and more efficient, but it will also ensure that you can properly maintain your engine for optimal performance.

There are a few types of tools and equipment that you will need for boat engine tuning. Firstly, having a good set of wrenches and sockets in various sizes is crucial for loosening and tightening nuts and bolts. Additionally, a torque wrench will come in handy for accurately applying the correct amount of torque to specific components.

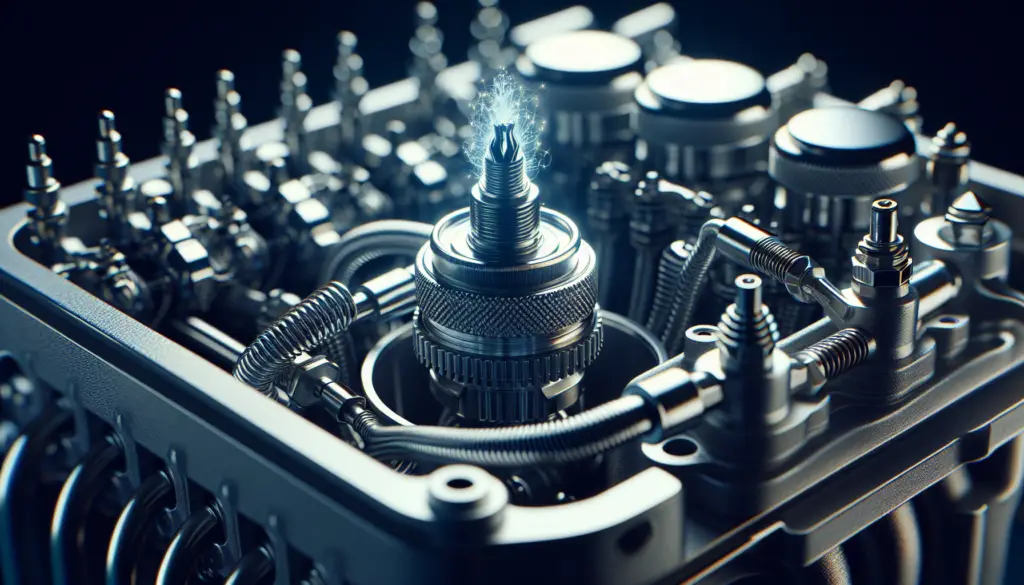

You will also need a set of screwdrivers, both flathead and Phillips, as these will be necessary for accessing and adjusting various parts of the engine. To check the spark plugs, a spark plug socket, gap gauge, and a wire brush will be necessary. Finally, a fuel pressure gauge, a compression gauge, and a tachometer are essential for measuring different aspects of your engine’s performance.

When considering the quality and durability of your tools and equipment, it is important to invest in high-quality items. Cheap or substandard tools may break easily and could potentially cause damage to your engine or make the tuning process more difficult. Durable tools, on the other hand, will last longer and provide more accurate results, ensuring that you can tune your engine effectively.

Pre-Tuning Inspection

Before diving into the tuning process, it is crucial to conduct a thorough pre-tuning inspection. This will help you identify any underlying issues or damage that may need to be addressed before proceeding. By examining the engine for damage or wear, you can catch any potential problems early on and prevent them from escalating.

During the inspection, it is important to check for loose or worn-out parts. Pay close attention to belts, hoses, and any other components that may show signs of wear or looseness. Tightening or replacing these parts will not only improve engine performance but also prevent potential breakdowns while out on the water.

Another crucial aspect of the pre-tuning inspection is inspecting the fuel system. Check for any leaks or clogs in the fuel lines, as these can significantly impact engine performance. Additionally, ensure that all fuel filters are clean and in good condition. If you notice any issues with the fuel system, it is important to address them before proceeding with the tuning process.

Spark Plug Maintenance

Spark plugs play a vital role in the combustion process of your boat engine. Keeping them clean and properly gapped is essential for optimal performance. Neglecting spark plug maintenance can result in misfires, decreased power, and reduced fuel efficiency.

To maintain your spark plugs, you will need to follow a few simple steps. Start by removing the spark plug wires using a spark plug socket. Once removed, inspect each plug for signs of damage or excessive wear. If any plugs appear dirty, use a wire brush to clean off any debris. Additionally, use a spark plug gap gauge to check the gap between the center and ground electrode. Adjust the gap if necessary to the manufacturer’s recommended specifications.

In some cases, spark plugs may be beyond cleaning and should be replaced. If you notice severe damage, corrosion, or a worn electrode, it is best to install new spark plugs. Replacing spark plugs at regular intervals, as recommended by the manufacturer, is a good practice to ensure optimal engine performance.

Air Filter Maintenance

Clean air filters are essential for the proper functioning of your boat engine. They prevent dirt, dust, and debris from entering the engine, improving overall performance and fuel efficiency. Neglecting air filter maintenance can lead to reduced airflow, increased fuel consumption, and potential engine damage.

Locating and removing the air filter will depend on the specific make and model of your boat engine. Generally, it is located in a housing near the carburetor or throttle body. Once located, carefully remove the housing cover and inspect the air filter for dirt and debris. If the filter is dirty, gently tap it against a hard surface to remove loose particles. In some cases, a vacuum or compressed air can be used to clean the filter. However, if the filter is heavily clogged or damaged, it is best to replace it with a new one.

Regularly inspecting and cleaning or replacing the air filter is a simple yet effective way to optimize your boat engine’s performance and longevity. It is essential to refer to your engine’s manufacturer guidelines for specific recommendations on air filter maintenance and replacement intervals.

Fuel System Cleaning

A clean fuel system is crucial for the proper functioning of your boat engine. Over time, fuel deposits, dirt, and debris can accumulate, clogging fuel injectors and reducing fuel efficiency. Regular fuel system cleaning helps maintain optimal engine performance and prevents potential issues down the line.

To clean the fuel system, there are a few steps that you can follow. Start by adding a fuel system cleaner to your boat’s fuel tank. This additive will help break down deposits and clean the fuel injectors. It is important to choose a fuel system cleaner that is compatible with your engine’s fuel type and follows the manufacturer’s instructions for proper usage.

Once the fuel system cleaner is added, run the engine at idle for the recommended duration specified by the manufacturer. This will allow the cleaner to circulate throughout the fuel system and dissolve any deposits or clogs. After the designated time, take the boat for a short ride to further clean the internal components.

Regularly using fuel additives designed for fuel system cleaning is an excellent practice to maintain an efficiently functioning engine. However, it is important to note that thorough professional cleaning may be required for heavily contaminated fuel systems.

Adjusting the Carburetor

The carburetor plays a critical role in the overall performance of your boat engine. It regulates the air-fuel mixture that is delivered to the engine cylinders, ensuring efficient combustion. Proper adjustment of the carburetor is essential for optimal engine performance and fuel efficiency.

Before adjusting the carburetor, it is important to understand its role in engine performance. The idle mixture and idle speed screws are key components of the carburetor that can be adjusted to optimize engine idle speed and fuel mixture. It is recommended to refer to your engine’s manufacturer guidelines for specific instructions on identifying and adjusting these screws.

To adjust the carburetor, start by warming up the engine to operating temperature. Then, turn the idle mixture screw clockwise until it is lightly seated, and then back it out counterclockwise to the manufacturer’s recommended setting. Next, adjust the idle speed screw to achieve the desired idle RPM specified by the manufacturer.

Regularly checking and adjusting the carburetor will ensure that your boat engine runs smoothly and efficiently. However, it is important to note that carburetor adjustment may require expertise or professional assistance for optimal results.

Checking and Adjusting Ignition Timing

Proper ignition timing is vital for the efficient operation of your boat engine. It determines when the spark plug fires, igniting the air-fuel mixture in the cylinders. Incorrect ignition timing can result in poor performance, decreased fuel efficiency, and potential engine damage.

Checking and adjusting the ignition timing requires a basic understanding of engine components. Locate the timing marks on the engine and use a timing light to illuminate them. Start the engine and point the timing light at the timing marks. The timing light will flash to indicate the exact timing of the spark plug firing. Compare the timing with the manufacturer’s recommended specifications and adjust if necessary.

Adjusting the ignition timing should only be done by qualified individuals or professionals familiar with engine tuning. Incorrect adjustment can lead to severe engine damage and should be avoided.

Monitoring Cooling System

The cooling system of your boat engine is vital for maintaining optimal operating temperatures and preventing overheating. Regular monitoring and maintenance of the cooling system can prevent costly repairs and ensure the longevity of your engine.

Start by checking the coolant levels in the radiator or coolant expansion tank. Low coolant levels can lead to overheating and potential engine damage. If necessary, top up the coolant to the manufacturer’s recommended level using the appropriate coolant type.

Inspect the cooling system for any visible leaks or signs of damage. Check all hoses and connections for cracks, leaks, or looseness. Additionally, examine the water pump for signs of leakage or wear. Any damaged or faulty components should be replaced promptly to prevent cooling system failure.

Regularly inspecting and maintaining the cooling system will help ensure that your boat engine remains cool and operates optimally. Failure to address cooling system issues can result in engine overheating, which can cause severe damage and expensive repairs.

Optimizing Propeller Performance

The propeller on your boat significantly impacts engine performance and overall efficiency. Selecting the right propeller size and pitch is crucial for achieving the desired speed and fuel economy. Additionally, regularly inspecting and repairing damaged propellers ensures proper function and prevents potential issues on the water.

Understanding the impact of propeller choice on engine tuning is important. A larger propeller will provide more thrust and low-end power, whereas a smaller propeller will offer higher top speeds but with reduced low-end power. Choosing the right propeller size and pitch depends on your boating needs, such as water conditions, desired speed, and vessel weight.

Inspect the propeller regularly for signs of damage, such as dents, cracks, or missing blades. Minor damage can often be repaired, but significant damage may require propeller replacement. It is important to have a professional evaluate and repair or replace damaged propellers to ensure proper balance and performance.

Optimizing propeller performance is essential for achieving maximum engine efficiency and enhancing the overall boating experience. However, it is important to note that propeller selection and repair should be performed by knowledgeable individuals or professionals for best results.

Regular Maintenance and Testing

Establishing a regular maintenance schedule is crucial for long-term engine performance and reliability. Regular testing and monitoring of the engine’s performance can help identify and address issues promptly, preventing further damage or expensive repairs.

Developing a maintenance schedule based on your engine’s specific requirements, as outlined in the manufacturer’s guidelines, is highly recommended. Regular tasks, such as oil changes, fuel filter replacement, and spark plug inspection, should be conducted at the recommended intervals to maintain optimal engine performance.

Regularly testing the engine’s performance is equally important. Monitoring factors such as engine idle speed, acceleration, fuel efficiency, and overall smoothness can help detect any potential issues. Any anomalies, such as rough idling or decreased power, should be addressed promptly to prevent further damage or reduced performance.

By adhering to a regular maintenance schedule and conducting routine testing, you can ensure that your boat engine operates optimally and remains reliable throughout its lifespan. Regular maintenance and timely addressing of any issues will help prevent costly repairs and ensure a pleasant and worry-free boating experience.