If you love fishing and own a boat, maintaining the longevity of your vessel’s engine is paramount. This article titled “Best Practices for Preventing Corrosion in Fishing Boat Engines” is for you. It addresses a common but menacing issue boat owners often encounter – corrosion. The piece provides insights, tips, and practical steps, you can implement to keep your engine corrosion-free, optimizing its function and lifespan. Giving your boat’s engine the care it deserves not only saves you expensive repair costs but also ensures that every fishing trip you embark on is smooth and incident-free. Now sit tight and brace yourself as this enlightening ride begins.

Understanding Corrosion in Fishing Boat Engines

Corrosion, an enemy lurking in the depths, can gradually eat away the lifeline of your fishing boat – the engine. Let’s delve into understanding what this nemesis is all about.

Knowing What Corrosion Is

Simply put, corrosion is a natural process, which converts a refined metal into a more chemically stable form, such as its oxide, hydroxide, or sulfide. When exposed to air or water, especially salt water, metals tend to react to form these compounds, slowly degrading the material. In the context of your boat engine, corrosion can severely affect its performance and lifespan.

Learning How Corrosion Affects Your Engine

Corrosion can render your reliable engine unreliable sooner than you may expect. The build-up of rust and other degradations can obstruct the normal functioning of engine components, leading to a gradual decrease in performance. Vital parts like engine cylinders, spark plugs, and exhaust systems are all susceptible to this menace. In the worst-case scenario, corrosion can lead to an engine breakdown, a situation you definitely want to avoid while at sea.

Types of Boat Corrosion

Understanding the enemy is the first step in warfare. Boat corrosion typically manifests in three forms: galvanic, electrolysis or stray current, and crevice. Galvanic corrosion happens when two dissimilar metals contact each other in a salty environment. Stray current corrosion, on the other hand, is due to electrical leaks from your boat’s wiring. Lastly, crevice corrosion takes place in the nooks and crannies of your engine where water gets trapped.All three types can be equally catastrophic if not identified and handled promptly.

The Major Causes of Corrosion in Fishing Boat Engines

Armed with knowledge about corrosion, let’s now focus on what causes it.

Exposure to Saltwater

Unsurprisingly, one of the leading causes of corrosion is saltwater. Saltwater speeds up oxidation processes, causing metals to degrade faster. When your boat is in sea water, your engine is at a higher risk of corrosion.

Lack of Proper Engine Maintenance

Absent or shoddy maintenance can also cause corrosion. Overlooking minor problems or postponing scheduled cleaning and inspections can lead to a build-up of corrosive elements in your engine, thereby prompting the onslaught of corrosion.

Ingress of Seawater into Engine Compartments

Seawater finding its way into engine compartments is a sure recipe for corrosion. Not immediately and thoroughly addressing this problem can lead to irreparable damage over time.

Aeration and Stray Currents

Lastly, when oxygen mixes with metal, rust forms. Ensuring your boat’s wiring is properly insulated is crucial, stray electrical currents could cause serious corrosion.

Spotting Signs of Corrosion

Knowing the early signs of corrosion can save your boat engine and your wallet from significant damage.

Color and Texture Changes

Look out for changes in color and texture. A corroded metal piece may exhibit a brown rust-like color or have rough texture.

Leaks and Excessive Moisture

Leaks can be an early indication of corroded parts. Keep a keen eye on your engine’s performance and note any unexplained moisture or dripping fluids.

Decreased Performance

Swing in performance levels can hint at underlying corrosion issues. Overheating, unduly high fuel consumption or unexplained loss of power may echo corrosion issues in your engine.

Choosing the Right Materials

Corrosion-Resistant Boat Engine Materials

Selection of the right engine parts materials can massively thwart corrosion. Opt for parts made of brass, copper, bronze, stainless steel, plastic, or other corrosion-resistant materials.

Choosing the Right Metals for Your Engine

Note that some metals are more corrosion-resistant than others. For example, stainless steel and bronze are typically more corrosion-resistant than aluminum or steel.

Understanding the Role of Metal Compositions in Corrosion

Each metal has a distinct reaction to different environments. Different metals react differently to the marine environment. Therefore, understanding the makeup and characteristics of the metals used in your engine can help combat corrosion.

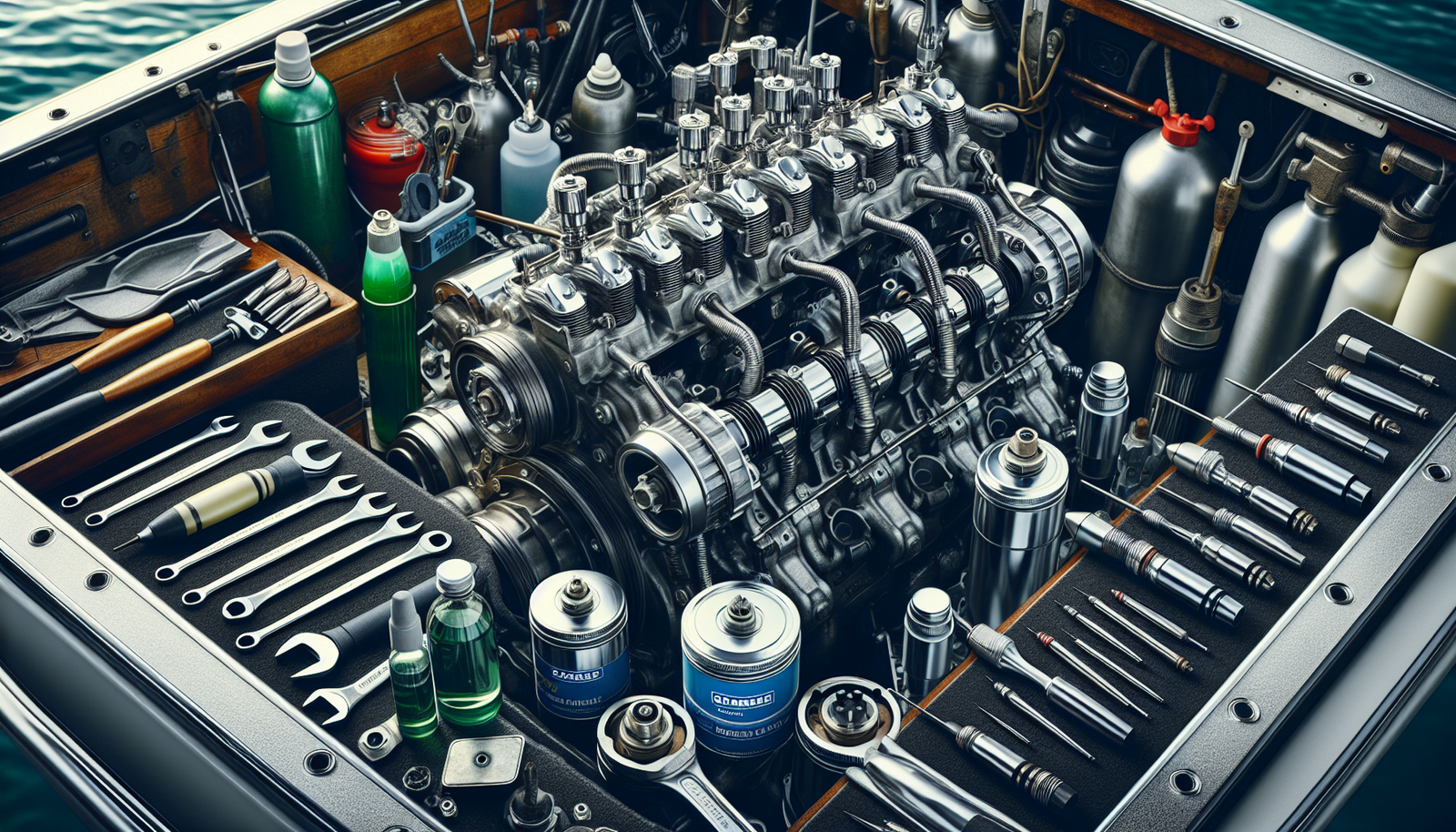

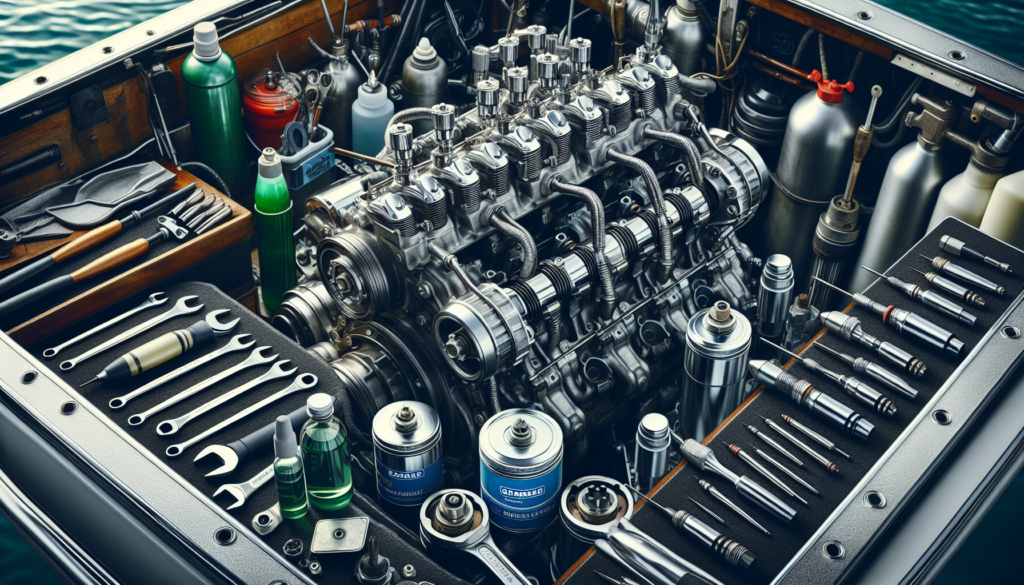

Proper Engine Installation and Maintenance

Ensuring Proper Engine Installation

A correctly installed engine can minimize crevices that might allow water to pool and induce corrosion. Always trust professionals for engine installation.

Regular Engine Checks

Regular checks on the engine can ward off corrosion. Monitor areas prone to corrosion and make it a habit to inspect these areas frequently.

The Importance of Routine Maintenance

Regular maintenance, including cleaning and engine tuning, can significantly reduce the likelihood of corrosion. An adequately maintained engine is a well-protected one.

Implementing a Schedule for Maintenance

Adhering strictly to a maintenance schedule can help you spot and tackle corrosion in its early stages. Consistency is crucial in maintenance.

Proactive and Regular Inspections

Setting Up Regular Inspection Schedules

Set up an inspection schedule and stick to it. Remember, corrosion starts small and grows bigger if ignored.

What to Look for During Inspections

Be attentive to the unusual color, rough surface texture, unexpected moisture, or performance variations. These could be signs of a corrosion problem.

Hiring a Professional for Inspections

Lack experience? Hire a professional. Their expertise can spot signs of corrosion you may miss and recommend remedial measures promptly.

Using Corrosion Inhibitors

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemicals that, when added in small amounts to an environment, effectively decrease the corrosion rate of a metal exposed to that environment.

Applying Corrosion Inhibitors on Your Boat Engine

Corrosion inhibitors can be used in several ways on your boat engine, either as part of engine oil, in coolant, or as a coating applied directly to engine components.

Choosing the Right Corrosion Inhibitor

Always choose a corrosion inhibitor designed for marine engines. They are formulated to work optimally in harsh marine conditions.

Proper Cleaning and Drying Practices

Cleaning Your Boat Engine Regularly

Aside from regular inspections, a well-cleaned engine is less likely to harbor corrosion.

Proper Drying Techniques to Prevent Corrosion

After cleaning, ensure your engine is dried properly. Water residue can induce corrosion.

The Role of Proper Storage in Corrosion Prevention

Proper engine storage when your boat is not in use can considerably reduce corrosion risks. Ensure your engine is dry and, ideally, run a dehumidifier in closed storage spaces.

Featured Technologies for Corrosion Prevention

Latest Coating Technologies

Coating technologies have improved significantly over the years. Modern coatings offer better corrosion resistance and longer protection periods.

Sacrificial Anodes

Sacrificial anodes, often made from zinc, are another excellent way to prevent corrosion. These anodes corrode instead of your engine, hence their name – sacrificial.

Cathodic Protection

Cathodic protection is a proven method for preventing corrosion. It involves connecting the engine metals to a ‘sacrificial’ metal that corrodes instead, sparing the engine.

Dealing with Corrosion Once It Occurs

Effective Methods for Treating Corrosion

If you spot corrosion, don’t panic. Remedies might include cleaning the rusted parts, coating them with rust inhibitors, or repainting them with corrosion-resistant paint.

Replacing Corroded Parts

In some cases, replacing corroded parts might be the best course of action. Replacing a corroded part immediately could save the rest of your engine.

Steps to Take When Serious Corrosion is Discovered

In case of extensive corrosion, consult professionals immediately. Remember, swift action can save further deterioration of your engine.

In conclusion, remember the old adage – prevention is better than cure. Following these tips and adopting a proactive approach is key to ensuring a corrosion-free and dependable fishing boat engine. After all, your boat’s reliable performance is crucial to an optimal fishing experience.