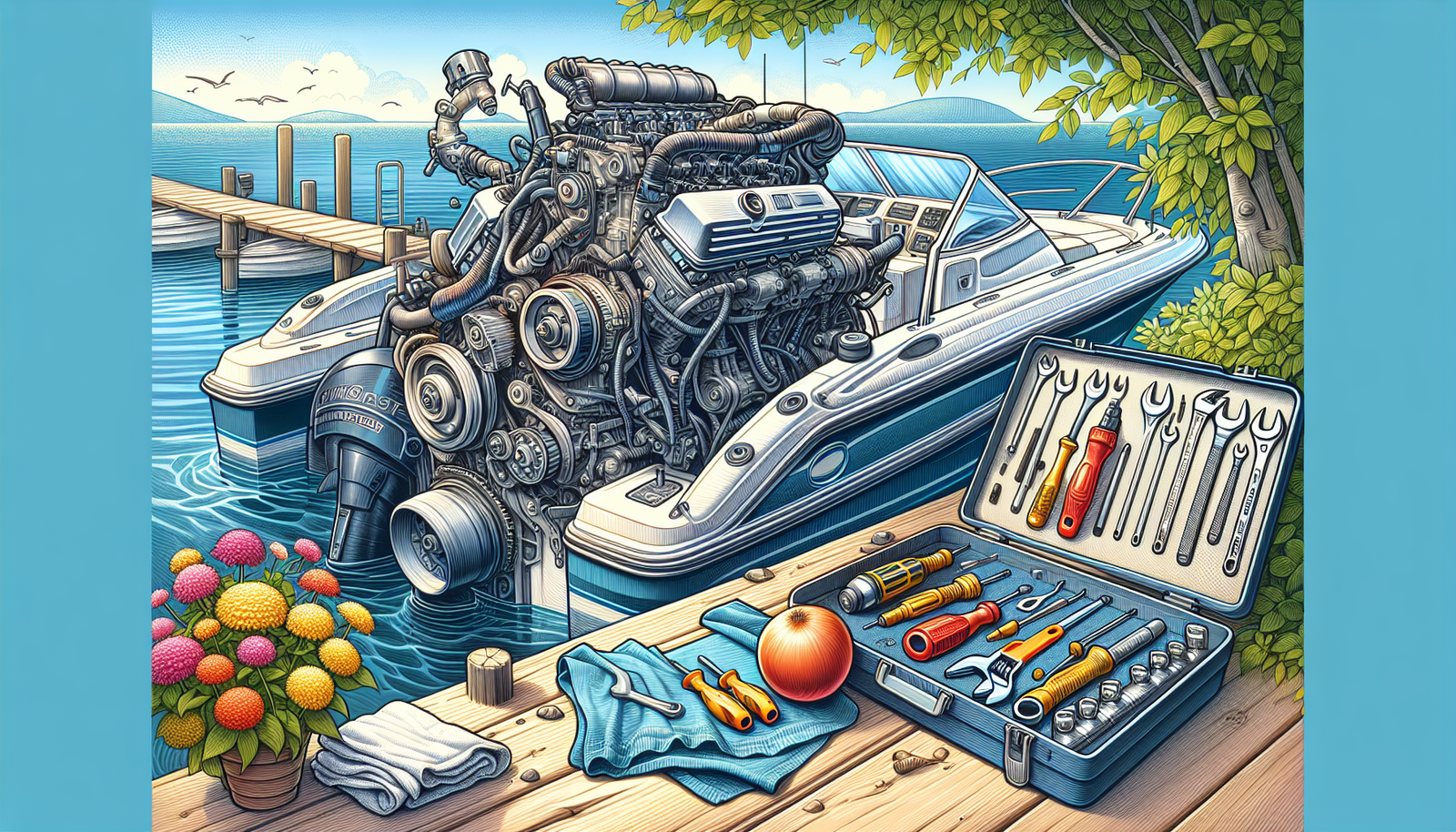

As the winter frost melts away and spring breezes start to dance across the water, it’s time to turn your attention to your boat. In this guide, “Best Practices For Spring Boat Engine Maintenance,” you’ll gain insights into preparing your vessel for the season ahead. From the small but vital tasks, such as battery care and propeller inspection, to more complex undertakings like filter changes and de-winterization of your boat’s engine, this article is set to equip you with knowledge and guidance you need for effective spring boat engine maintenance.

Understanding the importance of spring boat engine maintenance

As the winter season winds down and spring knocks on the door, it’s high time you prep your boat engine for the boating season. Regular maintenance guarantees that your vessel’s engine performs optimally, ensuring your safety and saving your pocketbook.

The factors contributing to the engine’s performance

A multitude of factors play into your engine’s performance. This includes how you run your engine, the quality of fuel you use, and most importantly, how frequently and thoroughly you maintain it. Ignoring regular maintenance may lead to decreased efficiency, sluggish performance, frequent breakdowns, or even a completely unusable boat. Therefore, remember to perform a thorough checkup routinely.

The economic benefits of regular engine upkeep

Regular engine upkeep has substantial economic benefits. For one, it circumvents the expense of major repairs or replacements due to unresolved minor issues. Furthermore, a well-tuned engine consumes less fuel, saves on fuel costs, and increases the lifespan of your boat.

The safety implications of thorough maintenance

Apart from economic benefits, the safety implications of a well-maintained engine are significant. Faulty engines can lead to disastrous scenarios at sea. Regular tune-ups spot potential problems that can be corrected, ensuring your safety.

Performing a basic visual inspection

The first step in spring boat engine maintenance is a basic visual inspection. Visual check-up allows you to spot apparent issues that might cause trouble down the line.

Checking the engine for visible wear and tear

Wear and tear on the engine are inevitable. However, unchecked wear may lead to serious issues. Inspect the engine for any visible signs of damage, such as leakages, discoloration, or unattached parts.

Identifying potential rust spots and corrosion

Rust and corrosion are a boat engine’s worst enemies. Check for rust spots or corrosion around the engine’s metal parts, particularly those closest to water. Neglecting these spots can lead to major engine problems.

Inspecting the belts and hoses for any cracks

Belts and hoses are essential for a functioning engine. Check them rigorously for any signs of cracks. Cracked belts and hoses tend to break easily, leading to engine failure at unforeseen moments.

The process of changing the engine oil

Changing the engine oil is a crucial step in maintaining your engine. It ensures the engine’s smooth running, extends its lifecycle and boosts performance.

Determining when to change the oil

Your boat’s engine oil should ideally be changed every 50-100 running hours, or at least once a year. However, always refer to your boat’s manual for manufacturer guidance on oil change frequency.

Choosing the right type of oil for your engine

Choosing the right oil is crucial. Marine engine oils differ from regular engine oils. They are specifically designed to provide better protection from rust and corrosion, factors that are often prevalent in a marine environment.

Step-by-step guide to changing the oil

Oil change isn’t rocket science. Firstly, warm up your engine. Next, turn it off and locate the drain plug. Use an oil extractor for easier drainage. Once done, replace the old oil filter with a new one. Lastly, refill the engine with new oil.

Managing the cooling system

Your boat’s engine cooling system plays a significant role in maintaining optimal engine temperature. An inefficient cooling system runs the risk of overheating, causing significant engine damage.

Identifying signs of an inefficient cooling system

Common signs of an inefficient cooling system include inconsistent engine temperature, leakage from the water pump, or even overheating. If you notice any of these signs, it’s time to inspect your system.

Ensuring the cooling system is properly flushed

Flushing out the cooling system eliminates the debris or sediment that may have settled over time. Make sure you flush your system thoroughly to ensure it’s free of any water impurities that could lead to corrosion or blockages.

Repairing or replacing faulty cooling system components

After flushing, inspect your cooling system for damaged parts. Fix or replace any faulty components immediately.

Inspecting the fuel system

The fuel system plays a vital role in your engine’s performance. A well-maintained system ensures that your engine gets the right amount of fuel at the correct pressure, ensuring optimal performance.

Checking the fuel lines and connections

Check your fuel lines for any breaks or leaks. Also, inspect the fuel hose connections and make sure they’re tight and secure. Loose connections can lead to fuel leaks, a dangerous situation.

Keeping the fuel tanks clean

A dirty fuel tank can lead to problems such as clogged fuel filters. So, ensure your fuel tanks are clean and devoid of any sediment or water.

Replacing the fuel filters as needed

Fuel filters prevent impurities from entering the engine and should be replaced as necessary. A blocked filter can restrict fuel flow, leading to a drop in engine performance.

Checking the battery condition

A properly functioning battery guarantees uninterrupted engine operation. Regular inspections can prevent unforeseen power failures.

Evaluating the battery charge level

Check your battery charge level using a voltmeter. A low charge level might mean your battery is unable to hold charge and may need replacing.

Cleaning the battery terminals

Ensure your battery terminals are clean and free from corrosion. A poor battery connection can result in inadequate power being transferred to the engine.

Assessing the need for a battery replacement

If your battery is unable to hold a charge, or the terminals have extensive corrosion, it might be time to replace the battery. A reliable battery is invaluable at sea.

Assessing the condition of the spark plugs

Spark plugs play a key role in initiating the combustion process in your engine. A faulty spark plug can cause your engine to run unevenly or even refuse to start.

Understanding the role of spark plugs in engine performance

Spark plugs ignite the air-fuel mix within the engine, providing the power needed to drive your boat. Regular checks ensure they continue to do their job effectively.

Recognizing the signs of worn-out spark plugs

If your engine is hard to start, idles roughly, or your boat lacks acceleration, your spark plugs may need replacement.

Replacing the spark plugs as necessary

If you notice any of the above signs or if your spark plugs haven’t been replaced for a while, it’s time for new ones. Always replace them with high-quality plugs recommended by your boat manufacturer.

Examining the propeller and the lower unit

The propeller and the lower unit play a crucial role in your boat’s movement. Regular check-ups ensure they are functioning optimally.

Inspecting the propeller for damage

Check your propeller for any visible damage, such as dents or cracks. A damaged propeller can lead to reduced boat speed and increased fuel consumption.

Checking the gear-case oil level in the lower unit

Monitor your gear-case oil level. Low oil levels can lead to gear failure. If the oil appears milky or discolored, it could indicate a leak which needs immediate attention.

Ensuring the secure mounting of the propeller

Check if your propeller is securely mounted. A loose propeller can lead to unnecessary vibrations, potentially causing damage to the drive system.

Maintaining the belts and pulleys

Your engine’s belts and pulleys play a significant role in connecting and driving various engine components. Regular inspections and timely replacements can prevent unexpected breakdowns.

Understanding the role of belts in your engine

Belts ensure the proper functioning of the alternator, water pump, and the drive system. A broken belt can leave you stranded at sea.

How to check for worn-out belts and pulleys

Inspect your belts for any signs of wear like cracks or fraying. Check the pulleys for any misalignment. Damaged pulleys can speed up belt wear and lead to failures.

Replacing the belts and pulleys as required

If you notice unusual noises or visible signs of wear on the belts and pulleys, they may need replacement. Always replace them with high-quality parts recommended by your boat manufacturer.

Preparing the boat engine for spring use

Now that you’ve checked and tended to the essentials, it’s time to kick start your engine.

Running the engine to check its performance

Run your engine for a while to check its performance. Listen for unusual sounds and monitor the engine’s response to throttle changes.

Making necessary adjustments for optimal performance

Based on your engine’s run-out, make the necessary adjustments such as regulating the idling speed, or tuning the carburetor to ensure optimal performance.

Scheduling regular maintenance throughout the boating season

Regular maintenance ensures a stress-free boating season. Schedule regular check-ups throughout the season based on your usage and keep your engine running smoothly.

In conclusion, spring boat engine maintenance is crucial for a secure and enjoyable boating season. So take the time to prepare your boat for the upcoming season. It ensures optimal performance, proves economically beneficial, and guarantees your safety at sea. Happy boating!