If you’ve ever dealt with aging boat engines, chances are you’ve encountered myriad issues. From failing parts to decreased performance, it’s a challenging task to keep these older engines running smoothly. “Essential Boat Engine Overhaul Tips for Older Vessels” is an article packed with valuable information and insights on this very issue. Designed with your needs in mind, the article shares a wealth of practical advice on maintaining, troubleshooting, and overhauling older boat engines. It’s the ultimate guide to longer engine life, improved performance, and stress-free sailing.

Understanding the Importance of Overhaul

Regular maintenance and proper care are the cornerstone of any long-lasting machinery, marine engines being no exception to the rule. Now, this may raise a relevant question in your mind. Why go for an overhaul when regular maintenance can keep things shipshape? Here’s where understanding the importance of an engine overhaul comes into play.

Knowing the lifespan of marine engines

Marine engines, just like their land-bound counterparts, have a definite lifespan. Factors such as usage, running hours, and maintenance can influence how long an engine lasts before it needs significant repairs. But no matter how well you maintain it or how carefully you use it, there will come a point when an overhaul is not optional but necessary.

Deciding when to opt for engine overhaul

So, how do you decide when it’s time for an overhaul? There are many signs. Your engine may be consuming more fuel than usual, or you may notice a reduction in power output. Perhaps there are visible signs of wear and tear, or maybe the engine is not running as smoothly as it used to. Do keep in mind, an engine overhaul is not about acting when the engine breaks down. It’s about seeing the signs early and taking action before expensive and extensive repairs become necessary.

Benefits of regular engine overhaul

A regular engine overhaul can bring many benefits. It’s an opportunity to address minor issues before they become major problems. It allows you to maintain optimal performance, efficiency, and reliability. Even safety concerns are nullified when your engine is functioning at its best. An overhaul ensures that your engine continues to give you the power, speed, and reliability you need while keeping fuel costs to a minimum.

Prerequisites Before Beginning the Overhaul

Before you dive into the engine overhaul process, there are a few prerequisites to consider.

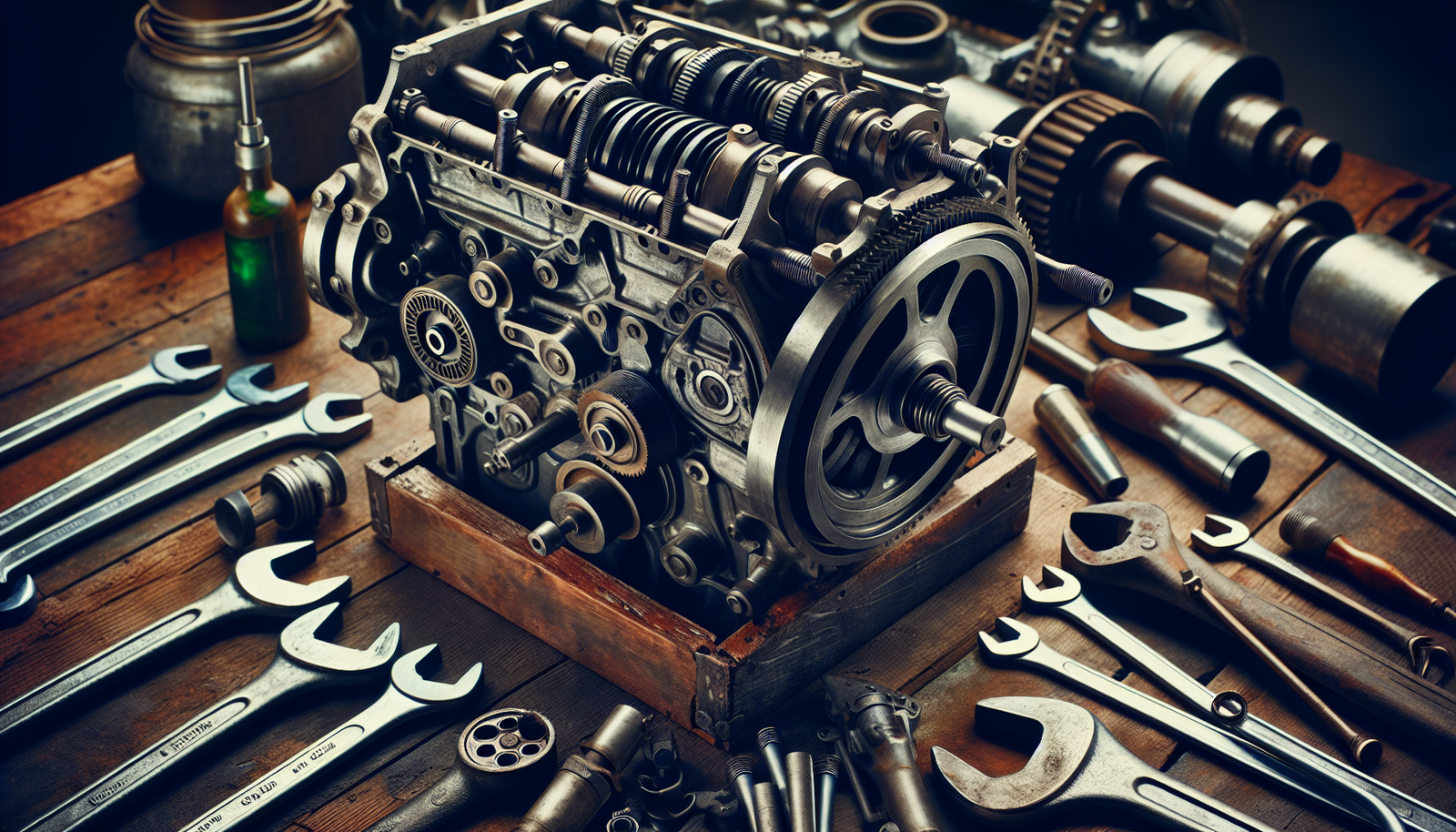

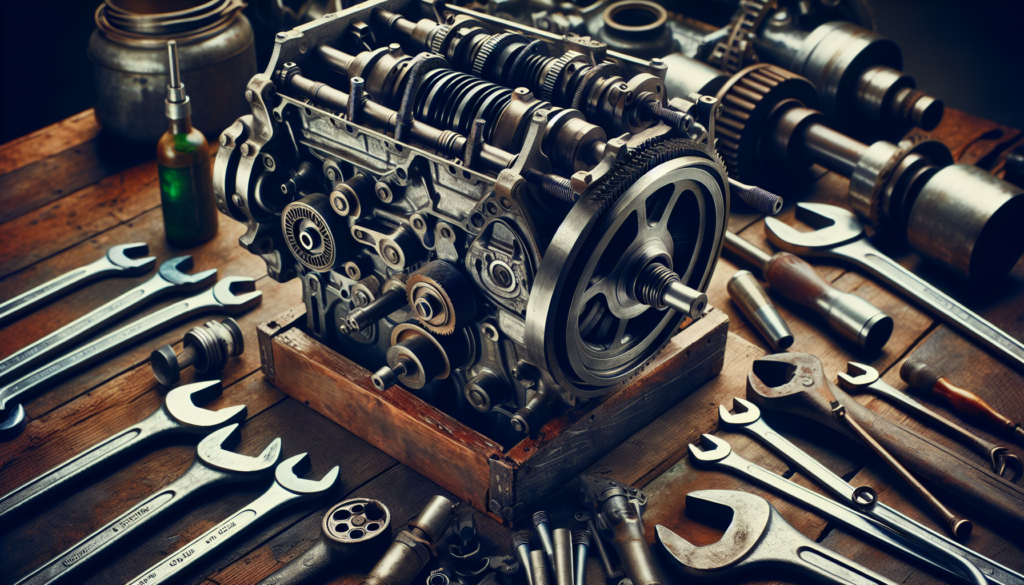

Acquiring the necessary tools and parts

You’ll need tools to take apart your engine and then put it back together. You’ll also need certain parts depending on what needs to be replaced during the overhaul. Make a list of the tools and parts you need based on the engine model and advice from your mechanic or service manual.

Reviewing the engine’s service manual

The service manual is your bible during an engine overhaul. It includes essential information about the engine, like its assembly and disassembly, parts, functions, and maintenance schedule. Going through it before starting your overhaul can bring valuable insights and prevent accidentally causing any damage.

Creating a conducive work environment

A clutter-free and well-lit space can make your task significantly easier. Arrange your tools and parts for easy access. Protection for yourself, like work gloves or goggles, is also an essential part of a conducive work environment.

Assessing the Condition of the Engine

Inspecting for visible signs of wear and tear

Once you’ve prepared everything necessary, start by visually inspecting the engine for signs of wear and tear, like broken seals or rust on the exterior components. This can give initial hints about what might be going on inside.

Checking the oil and coolant levels

Then check the oil and coolant levels. Low levels might indicate leaks or increased consumption which could signal a problem. Besides checking the level, the color and consistency of the oil can also indicate engine health.

Testing for leaks or unusual noises

Start the engine and listen carefully for any unusual noises. This could include knocks, pings, or grinding noises. Leaks, heat, or smoke are other warning signs that something isn’t right.

Dismantling the Engine

Safely shutting down the engine

It is crucial to follow proper protocol for shutting down the engine safely before you begin dismantling. Disconnect the battery and wait for the engine to cool down to a safe temperature.

Gradually disassembling the engine parts

The process of disassembling the engine should be slow and cautious. Each part should be handled carefully to avoid any damage. Make sure to follow the instructions in your service manual always.

Properly labelling and organizing the engine components during teardown

To avoid confusion during reassembly, label and organize all the parts as you dismantle them. A neatly laid out and organized workspace not only makes the whole process less stressful, but it also drastically reduces the chances of missing parts or assembling incorrectly.

Cleaning and Inspecting Disassembled Parts

Using appropriate solvents for cleaning

Usually, a cleaning solvent is used to remove built-up carbon, rust, or grime from the parts. Make sure to use solvents suitable for your engine components.

Carefully examining parts for defects

A careful examination of all parts is crucial at this point. Look for cracks, abnormal wear, burnt or failing seals, shaft damage, or other potential issues.

Determining which parts need replacing

Based on your inspection, decide which parts need to be replaced. This could range from simple seals and gaskets to more main components like cylinders or pistons.

Purchasing Replacement Parts

Identifying reputable suppliers

Only buy replacement parts from reputable suppliers who can provide good quality and genuine parts. It may be cheaper to get non-genuine parts, but they may not perform as well and can potentially damage your engine.

Ensuring compatibility of new parts with the old engine

Ensure the replacement parts you buy are compatible with your engine. Check all specifications carefully before any purchase, or you may end up having to return parts that don’t fit.

Understanding the warranty on the replacement parts

Most replacement parts come with a warranty, but it’s best to confirm this before purchase. This can protect you in case of premature failure of the new part.

Rebuilding and Reinstalling the Engine

Correctly assembling the cleaned and new parts

Rebuilding the engine involves correctly fitting back all the cleaned and new parts. Here, your service manual will be an indispensable guide. It will provide step-by-step instructions for refitting all engine parts.

Properly reinstalling the engine following the service manual

Once the engine is rebuilt, it needs to be reinstalled in its position. Again, refer to your service manual for the correct method of installation.

Checking for proper installation

After the engine is reinstalled, check all connections, fittings and mounts to ensure they are secure. Incorrect fitting can cause leaks, vibrations, or other issues in the future.

Testing the Overhauled Engine

Conducting initial start-up and run-in

The engine should be allowed to idle at a low rpm for a while on its first start after the overhaul. This allows the oil to circulate and the new parts to adjust before running at full load.

Monitoring the engine’s temperature and oil pressure

Monitor the engine’s temperature and oil pressure during its first few runs. Unusual readings can indicate potential issues that should be addressed immediately.

Handling engine malfunctions after overhaul

Even with careful overhaul, there’s always a chance for some initial snags. If there are any malfunctions, turn off the engine immediately and review your work. Sometimes, it’s a simple oversight, and other times it might require a professional’s intervention.

Maintenance and Care After Overhaul

Regularly changing oil and coolant

Regular oil and coolant changes are essential for maintaining engine health post-overhaul. Always follow the manufacturer’s recommended oil and coolant types and changing intervals.

Ensuring proper use and not overworking the engine

Avoid overworking the engine, especially immediately after the overhaul. Instead, let it break in gently before pushing it to its limits.

Planning a routine maintenance schedule

Regular maintenance keeps your engine running efficiently for longer. Make a schedule for oil changes, coolant changes, and regular inspections and stick to it.

Avoiding Common Overhaul Mistakes

Rushing the overhauling process

A common mistake people make during overhauls is rushing the process. It’s vital to take your time and work methodically, especially if you’re performing an overhaul for the first time.

Neglecting the service manual

Your service manual has all the essential information you need for your engine overhaul. Ignoring it increases the chances of making mistakes.

Using non-compliant parts or tools

Equally important is following the manual’s recommendations for parts and tools. Trying to save a few bucks on cheaper parts or tools can lead to severe damage in the longer run.

Not seeking professional help when needed

Sometimes the issues you come across during your engine overhaul might be beyond your understanding or ability. Never hesitate to seek help from a professional in such cases. It might cost a little, but it can save you bigger costs and hassles in the future.

In conclusion, an engine overhaul is a vital process that can extend the life of your marine engine significantly. But for it to be effective, you need to understand its importance, follow the right protocol, and avoid common mistakes. With all the information given above, you should be prepared to tackle an engine overhaul with confidence but don’t forget to always have a professional in your corner, just in case.