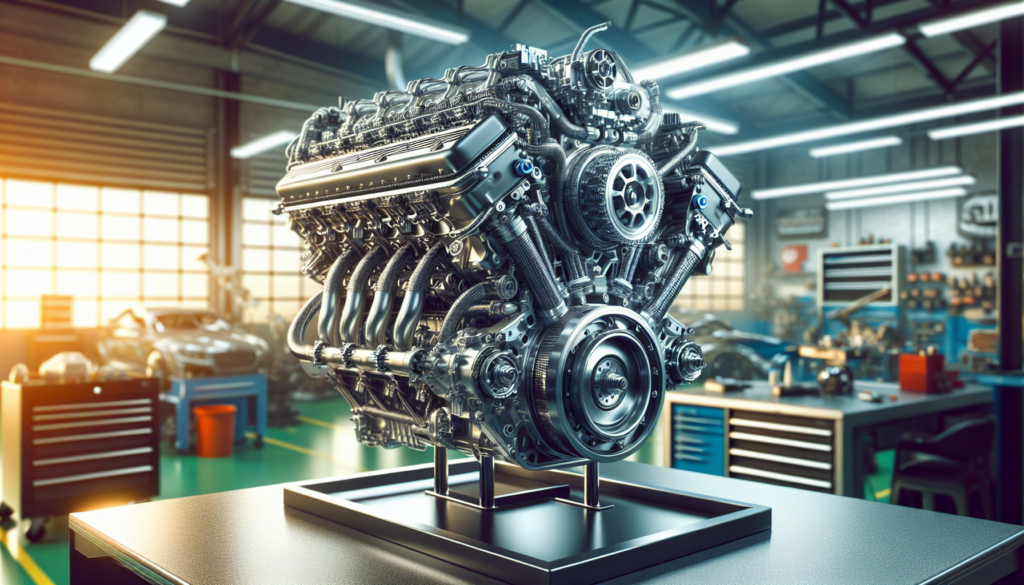

Do you ever find yourself wanting a quieter and smoother ride? If so, then you will be intrigued to discover how engine customization can enhance sound and vibration control in your vehicle. By making specific modifications to your engine, you can significantly improve your driving experience by reducing noise and minimizing vibrations. In this article, we will explore the various techniques and customization options available to help you achieve a more enjoyable and serene ride. So, let’s dive in and explore the world of sound and vibration control through engine customization!

Enhancing Sound and Vibration Control

Understanding the Importance of Sound and Vibration Control

When it comes to vehicles, sound and vibration control play a crucial role in enhancing the overall driving experience. Excessive noise and vibrations can not only be annoying but also lead to driver fatigue and discomfort. Moreover, a noisy vehicle can negatively impact the perception of quality for both the driver and passengers. Therefore, it is essential to understand the importance of sound and vibration control and take appropriate measures to improve them.

Common Issues and Challenges with Sound and Vibration Control

Sound and vibration control can present a variety of challenges for vehicle manufacturers. Common issues include excessive engine noise, vibration transfer to the vehicle cabin, audible exhaust noise, resonance, and structural vibrations. These problems can be caused by various factors such as engine design, component selection, and vehicle architecture. Overcoming these challenges requires a comprehensive approach that involves customization and optimization of the engine and its components.

Benefits of Engine Customization for Sound and Vibration Control

Engine customization offers numerous benefits when it comes to sound and vibration control. By customizing the engine, manufacturers can achieve enhanced vehicle performance, improved noise and vibration control, and flexibility in tuning and adjustments. Customization also provides an opportunity for brand differentiation, allowing manufacturers to create unique driving experiences for their customers. Furthermore, customization options can be tailored to different applications, ensuring that specific sound and vibration requirements are met.

Factors to Consider Before Customizing an Engine

Before diving into engine customization for sound and vibration control, there are several factors that need to be carefully considered. One crucial factor is cost and budget constraints. Customization can often incur additional expenses, so manufacturers must evaluate their budget limitations and weigh the potential benefits against the investment required. Additionally, compatibility with the existing engine and vehicle is essential to ensure a seamless integration of customized components. Engine reliability and durability, regulations and emission compliance, available resources and expertise, and project timeline should also be taken into account before proceeding with customization.

Choosing the Right Components for Sound and Vibration Control

Selecting the right components is vital for achieving effective sound and vibration control. Engine mounts and dampers, exhaust systems and mufflers, air intake systems, sound insulation and damping materials, electronics and control systems, as well as performance tuning tools and software, all play a significant role in reducing noise and vibrations. Understanding the functions of each component and their interactions with the engine is crucial for making informed choices. Manufacturers should consider factors such as design, material selection, and compatibility with the existing system when selecting components.

Ensuring Compatibility with Existing System

One challenge in engine customization for sound and vibration control is ensuring compatibility with the existing system. Before making any modifications, it is important to assess the current sound and vibration control system thoroughly. Integration and retrofitting challenges may arise, and careful consideration must be given to ensure that the customized components can seamlessly work with the existing system. Compatibility with original equipment manufacturer (OEM) components is also essential to maintain the overall performance and reliability of the vehicle. Validation and testing of the customized system should be conducted to ensure its effectiveness and compatibility.

Working with OEMs and Aftermarket Suppliers

Collaboration with OEMs and reliable aftermarket suppliers is crucial when it comes to sound and vibration control. Working with OEMs allows manufacturers to leverage their expertise and access to original components, ensuring the customization process aligns with the overall design and performance specifications of the vehicle. Identifying reliable aftermarket suppliers is equally important, as they offer additional options for customization and can provide specialized components tailored to specific sound and vibration requirements. Quality assurance and component certification should be considered to ensure the performance and reliability of the customized system. Maintaining warranty and support from OEMs is also essential to address any potential issues that may arise post-customization.

Engine Mounts and Dampers for Sound and Vibration Control

Engine mounts and dampers are critical components for sound and vibration control. They help to isolate the engine from the vehicle chassis, reducing vibrations and minimizing their transfer to the cabin. Proper selection of engine mounts and dampers, considering factors such as types, material selection, and design, can significantly contribute to noise reduction and enhanced driving comfort. Hydraulic and active mounting systems, as well as various vibration isolation techniques, offer different levels of effectiveness in controlling vibrations. Performance evaluation and testing of engine mounts and dampers are essential to ensure their functionality and compliance with sound and vibration control requirements.

Using Sound Insulation and Damping Materials

Sound insulation and damping materials are essential for reducing noise in vehicles. These materials are typically applied to various areas like the firewall, floor, doors, and ceiling to mitigate noise transmission. Sound insulation materials absorb and block sound waves, while damping materials reduce vibrations and resonance. Choosing the right combination of insulation and damping materials is crucial for achieving optimal noise reduction. Manufacturers need to consider factors such as material properties, thickness, and installation techniques to ensure effective sound control.

Tuning Exhaust Systems for Sound Reduction

The exhaust system plays a significant role in sound control. Understanding exhaust noise sources and their impact on sound is essential for tuning the exhaust system to achieve desired noise levels. Different types of exhaust systems, such as straight-through, chambered, and turbocharged, produce varying levels and tonal qualities of sound. Design considerations, such as the inclusion of resonators and mufflers, can help attenuate exhaust noise. Measuring and optimizing sound levels through techniques like sound mapping and flow analysis can assist in achieving a balanced approach between performance and compliance with noise regulations.

Understanding Sound and Vibration Control

The Basics of Sound and Vibration

Sound and vibration are inherent characteristics of any engine and vehicle. Sound refers to the audible waves produced by vibrating objects, while vibration refers to the oscillating and shaking movements caused by mechanical forces. In a vehicle, sound and vibration are primarily generated by the engine and its components, as well as from the interaction of tires with the road surface. Understanding the basics of sound and vibration is crucial for identifying and addressing potential issues in sound and vibration control.

The Impact of Sound and Vibration on Vehicle Performance

Excessive sound and vibration can have a significant impact on the overall performance of a vehicle. Excessive noise can hinder driver concentration, leading to potential safety hazards on the road. Moreover, prolonged exposure to excessive sound and vibration can result in driver fatigue and reduced comfort. This, in turn, can affect the vehicle’s handling and overall driving experience. Therefore, achieving effective sound and vibration control is essential for ensuring optimal vehicle performance in terms of safety, comfort, and overall driving enjoyment.

Compliance with Noise and Vibration Regulations

Regulations regarding noise and vibration have become increasingly stringent in recent years. Governments and regulatory bodies have implemented guidelines and standards to address the issue of excessive noise and vibration in vehicles. Compliance with these regulations is not only important for legal and environmental reasons but also directly affects the marketability and acceptance of vehicles. Manufacturers must ensure that their vehicles meet the required noise and vibration standards to maintain regulatory compliance and provide a positive customer experience.

The Role of Engine Customization

Engine customization offers a valuable avenue for achieving sound and vibration control. By customizing various aspects of the engine, manufacturers can fine-tune its characteristics, ensuring optimal sound quality and vibration control. Customization can involve modifications to engine design, component selection, and tuning parameters. The ultimate goal is to strike a balance between performance, efficiency, and sound and vibration control. Engine customization allows manufacturers to tailor the driving experience to meet specific requirements and differentiate their brand from competitors.

Improving Comfort and Reducing Driver Fatigue

One of the primary goals of sound and vibration control is to enhance driving comfort and reduce driver fatigue. Excessive noise and vibrations can have a negative impact on driver comfort, making the driving experience unpleasant and potentially causing physical discomfort and fatigue. By implementing effective sound and vibration control measures, manufacturers can create a more comfortable and enjoyable driving environment. Reduced noise and vibrations contribute to lower driver fatigue levels and increased focus, resulting in improved safety and overall driver satisfaction.