Get ready to master the art of maintaining the lifeblood of your boat – the fuel system. “How To Prevent Fuel System Issues In Boat Engines” arms you with the knowledge you need to keep your boat running smoothly and maximize its lifespan. This guide will cover tips and tricks that will empower you to tackle potential fuel system problems head-on, ensuring your sailing journey remains utterly enjoyable and hassle-free. Forget about getting stuck in the middle of the sea due to engine issues – this detailed guide is your ticket to seamless sailing each time.

Understanding the Basics of Boat Engine Fuel Systems

Navigating the waters can be more of a breeze if you understand the basics of boat engine fuel systems. This knowledge can save you a significant amount of downtime and expenses with regards to maintenance and repair.

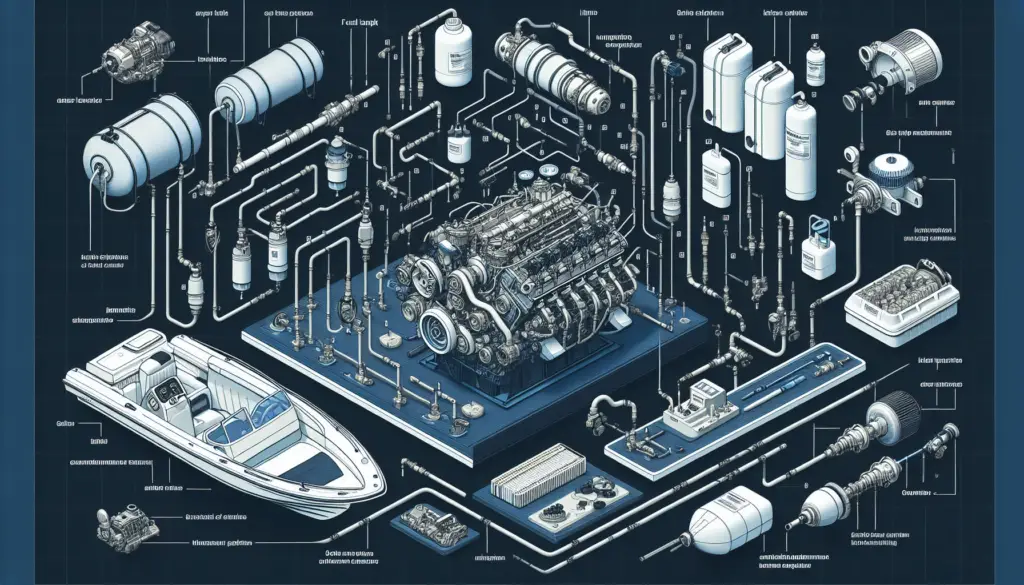

Types of Boat Engine Fuel Systems

There are primarily two types of fuel systems you’ll find in boats: the carbureted and the fuel injected systems. Carbureted systems are generally found in older models and they work by utilizing vacuum pressure to pull fuel into the engine. On the other hand, fuel injected systems, which are common in modern boat engines, use pressure to push fuel into the engine. Both systems have their pros and cons, and knowing which one your boat operates on is key to troubleshooting and maintenance.

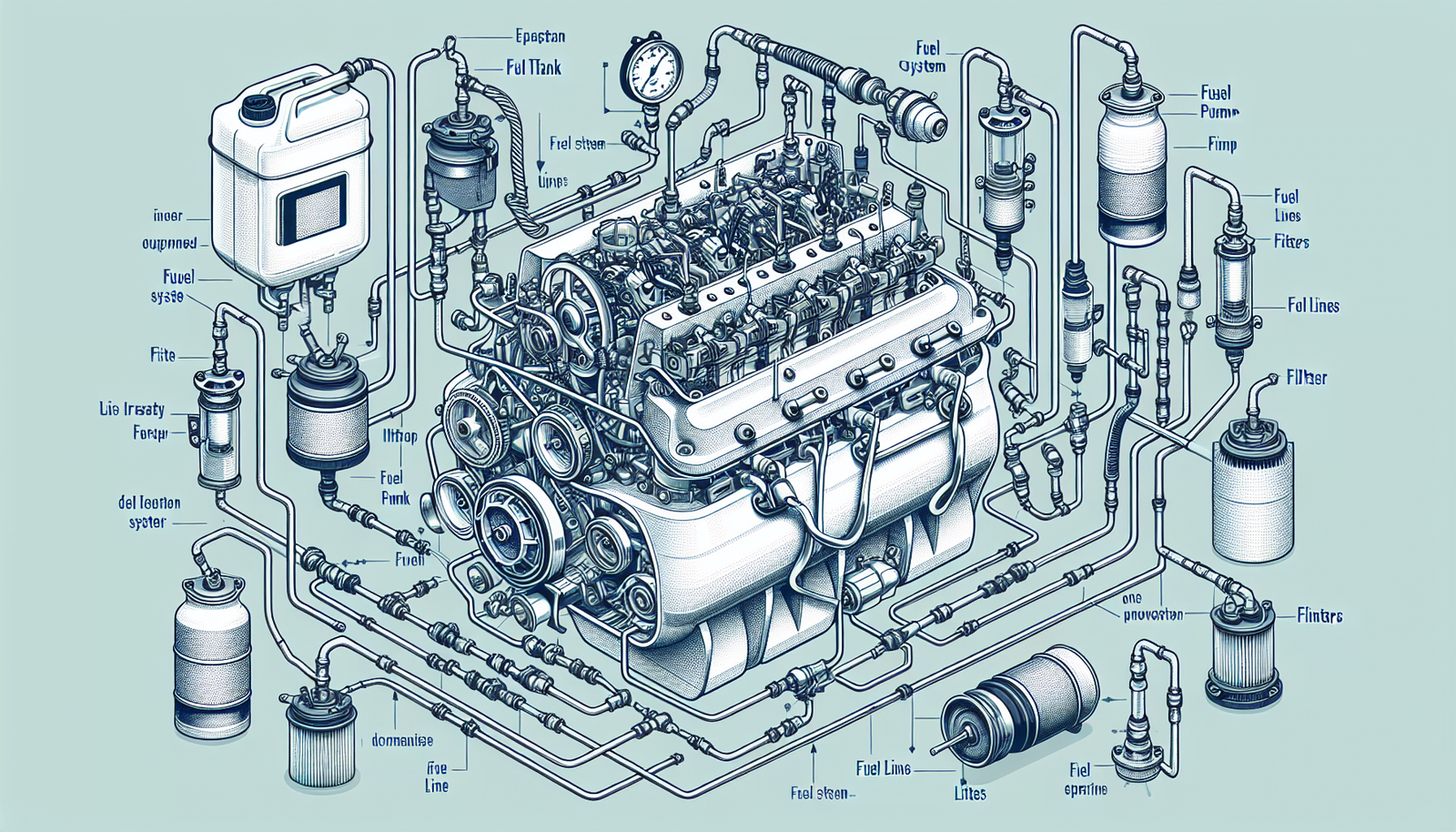

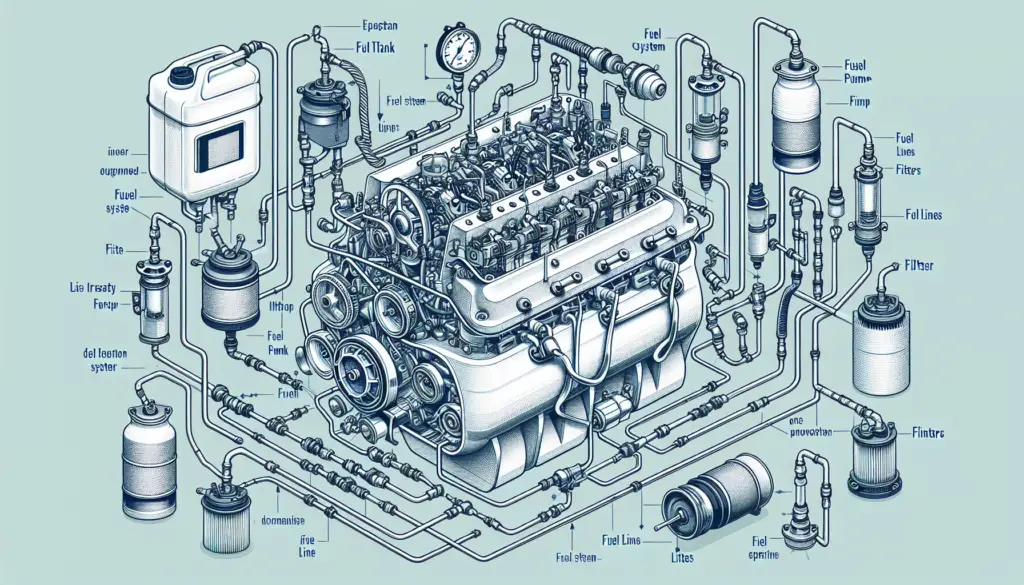

Components of a Boat Fuel System

A typical boat fuel system comprises the fuel tank, fuel lines, fuel filter, fuel pump, and the engine’s fuel delivery system (either carburetor or fuel injection system). The fuel tank stores the fuel, which the fuel pump then moves through the fuel lines. The fuel filter cleans the fuel before it gets to the engine, and the carburetor or injector then delivers the fuel to the engine.

Importance of Proper Fuel System Maintenance

Proper fuel system maintenance is crucial to the overall performance of your boat. Regular maintenance helps prevent common problems such as engine stalling, poor fuel economy, and fuel leaks. Beyond improved performance, well-maintained fuel systems enhance the safety of your boat, as it minimizes risks associated with fuel leaks and engine failures.

Common Fuel System Issues in Boat Engines

To maintain an efficient fuel system, you must familiarize yourself with some common fuel system issues and how to troubleshoot them.

Engine Stalling and Surging

Engine stalling is when your boat’s engine suddenly stops running, usually due to a problem with its fuel supply or fuel-to-air ratio. Surging, on the other hand, occurs when the engine maintains inconsistent speeds despite a steady input on the throttle. Both stalling and surging can be caused by problems such as a dirty fuel system or failing components in the fuel system.

Poor Fuel Economy

If you notice that your boat’s fuel economy is deteriorating, it could be a sign of an issue within the fuel system. Issues could include a clogged fuel filter, problems with the fuel injection system, or low-quality fuel.

Engine Misfiring or Backfiring

Engine misfiring or backfiring are typically signs of a faulty fuel system. Misfires happen when the fuel is not burning properly in the engine, while backfires occur when unburnt fuel ignites outside the engine’s combustion chambers.

Fuel Leaks

Fuel leaks can occur in different parts of your fuel system, from the tank, fuel lines to the engine itself. If you’re noticing a strong petrol smell, it could be a sign of a fuel leak, and it’s essential to address it promptly for safety reasons.

Principles of Preventive Maintenance

Preventive maintenance is the best way to keep your boat’s fuel system in optimal condition. Ensuring that minor issues are caught and addressed early can save you from costly repairs down the line.

Scheduled Inspections

Having a regular inspection schedule for your boat’s fuel system is critical. Scheduled inspections allow you to catch potential issues early, before they can cause significant damage or performance issues.

Preventive Maintenance Procedures

preventive maintenance procedures for a boat fuel system include cleaning the fuel tank, changing the fuel filters, inspecting and replacing fuel lines, and ensuring the fuel system is properly ventilated.

Importance of Using High-Quality Fuel

using high-quality fuel is essential for maintaining your boat’s performance and longevity. High-quality fuels burn cleaner and more efficiently, decreasing the likelihood of issues like clogged fuel filters and dirty fuel tanks.

Proper Storage of Boat Engines

proper storage during the off-season can prevent a multitude of issues, including fuel system problems. Understanding how to properly store your boat engine can ensure it’s ready to run when the season starts.

Avoiding Fuel Contamination during Storage

To avoid fuel contamination during storage, you should always fill your tank to prevent condensation. Also, consider using a fuel stabilizer to prevent the fuel from breaking down over time.

Proper Engine Draining procedures

Before storing your boat, make sure to properly drain the engine. This includes draining the fuel system to prevent any fuel from becoming stale and causing future issues.

Importance of Engine Covers

Covering your engine during storage can help keep it clean and free from dust and debris. This can prevent clogging in your fuel system when the boating season starts again.

Dealing with Ethanol in Fuel

Ethanol in fuel can lead to several issues in boat engines. It’s vital to understand these implications and how to mitigate them.

Understanding the Consequences of Ethanol

Ethanol can be damaging to numerous parts of a boat’s fuel system. It tends to attract water, which can result in corrosion and damage to metal parts. At high concentrations, it can even cause phase separation, where water and fuel separate, leading to engine issues.

Ways to Mitigate Ethanol-Related Issues

To prevent ethanol-related issues, always use marine-grade ethanol treatments. Also, pay attention to fuel turnover as ethanol-blended fuel tends to stale faster. Always maintain a full tank to minimize the amount of humid air and hence, water condensation in the tank.

Ethanol-Proofing Your Engine

Using ethanol-proof materials throughout your fuel system can help ward off many ethanol-related problems. Recurrent inspections and timely replacements of vulnerable components such as fuel lines can also aid in proofing your boat engine against ethanol.

Fuel Filter Maintenance

The fuel filter is a critical component in a boat’s fuel system, and understanding its role is vital to maintaining it correctly.

Understanding the Role of Fuel Filters

Fuel filters play a pivotal role in ensuring the fuel that goes into your engine is clean and free of any contaminants. They trap dirt, dust, and other debris present in the fuel to prevent them from getting into the engine.

When and How to Replace Fuel Filters

Fuel filters should ideally be replaced after every 50 to 100 hours of operation, or at least once a season. When replacing, always ensure to use marine-grade filters suitable for your specific engine type.

Signs of a Clogged Fuel Filter

A clogged fuel filter can cause several performance issues such as stalling, poor acceleration, and starting problems. Regular inspections can help catch clogs before they cause significant damage.

Fuel Tank Cleaning and Maintenance

Just like the fuel filter, maintaining a clean fuel tank is crucial for your boat engine’s health.

Signs of a Dirty Fuel Tank

Signs of a dirty fuel tank include frequent clogging of the fuel filter, poor engine performance, and signs of debris in the bottom of the tank.

How to Clean a Fuel Tank

Cleaning a fuel tank involves emptying it, then using a specially made fuel tank cleaning solution to dislodge and remove any debris or sludge build-up.

Avoiding Water Contamination in a Fuel Tank

Avoiding water contamination in your fuel tank is key. Always ensure your tank is full when storing your boat to prevent condensation, and regularly inspect the tank for any signs of water.

Fuel Line Checking and Maintenance

Proper maintenance of the fuel line contributes significantly to the overall performance of your boat engine.

Spotting Fuel Line Problems

Cracks, leaks, and noticeable wear and tear are all signs of fuel line problems which could lead to fuel leaks or contamination.

How to Maintain and Replace Fuel Lines

Regular visual inspections are the key to maintaining fuel lines. Any sight of damage or wear should prompt immediate replacement.

Preventing Fuel Line Deterioration

Many factors can lead to fuel line deterioration, including the use of low-quality fuel and exposure to environmental factors. Always store your boat appropriately and consider using a fuel stabilizer.

Fuel Pump Inspection and Maintenance

understanding the function of the fuel pump, recognizing symptoms of a failing fuel pump, and knowing its maintenance and replacement strategies will keep your boat engine running smoothly.

Understanding the Function of the Fuel Pump

The fuel pump is responsible for moving fuel from the tank to the engine. It plays a critical role in ensuring your engine consistently receives the right amount of fuel.

Symptoms of a Failing Fuel Pump

frequent engine stalls, power loss under stress, and undue engine heat are some symptoms of a failing fuel pump.

Maintenance and Replacement of Fuel Pumps

Regular inspection is the key. A failing pump should be replaced immediately to prevent severe engine damage.

Proper Ventilation of the Fuel System

Having a properly ventilated fuel system is crucial to maintaining a well-functioning engine.

Understanding the Importance of Fuel System Ventilation

Ventilation allows fumes and pressure from the fuel to escape, preventing build-up and potential damage.

Tips for Proper Fuel System Ventilation

Ensure the vents are clean and unblocked. Regularly check seals and valves for deterioration.

Typical Ventilation Issues and Their Solutions

Common ventilation issues include obstructed vents and faulty valves. Regular inspections can identify these problems early, and replacing faulty parts immediately can prevent more significant issues down the line.