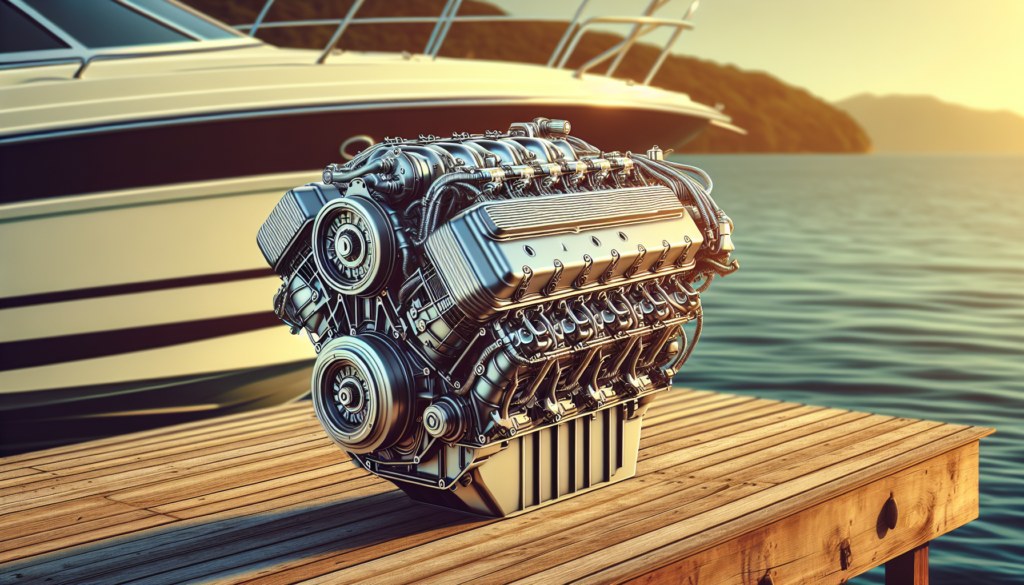

You’ve finally got your hands on that shiny new boat, haven’t you? Or you’ve just replaced your trusty old boat’s heart with a brand new engine and are raring to hit the water. Exciting as it may be, that newly minted motor needs some tender loving care before you really put it into gear. In this article, you’ll discover the best techniques on how to properly break in your new boat engine. An essential guide to protecting and maximizing your investment, assuring your engine lasts long, runs smooth, and serves you well in the numerous nautical adventures that lie ahead. That ocean beckons, doesn’t it? So let’s make sure you’re all primed and prepared to navigate it!

Understanding the Importance of Engine Break-In

When you purchase a new boat, one of the most critical steps to ensuring its longevity and performance is breaking in the engine correctly. Just as you wouldn’t begin a marathon with a sprint, you shouldn’t jump into high-speed operation with your fresh-out-of-the-box boat engine.

Why breaking in the boat engine is crucial

Proper engine break-in is crucial because it promotes engine longevity and peak performance. It ensures that all moving parts mesh well together and create a seamless operation. The break-in process helps to shape the cylinder walls, rings, and all other moving parts together. It’s like a compatibility process that helps them find the right movement rhythm.

Long-term effects of improper engine break-in

If you fail to perform a proper engine break-in, you could face severe consequences. These may include reduced engine life, higher fuel consumption, and even an increase in engine oil consumption. Besides, it may lead to operational failures, such as the inability to reach maximum RPM or overheating, which could cause significant damage to your engine.

Benefits of proper engine break-in

On the other hand, a correctly broken-in engine provides benefits such as enhanced fuel-efficiency, better performance, less engine oil consumption, and longer engine life. It’s an essential step towards responsible boat ownership and ensures peace of mind on the water.

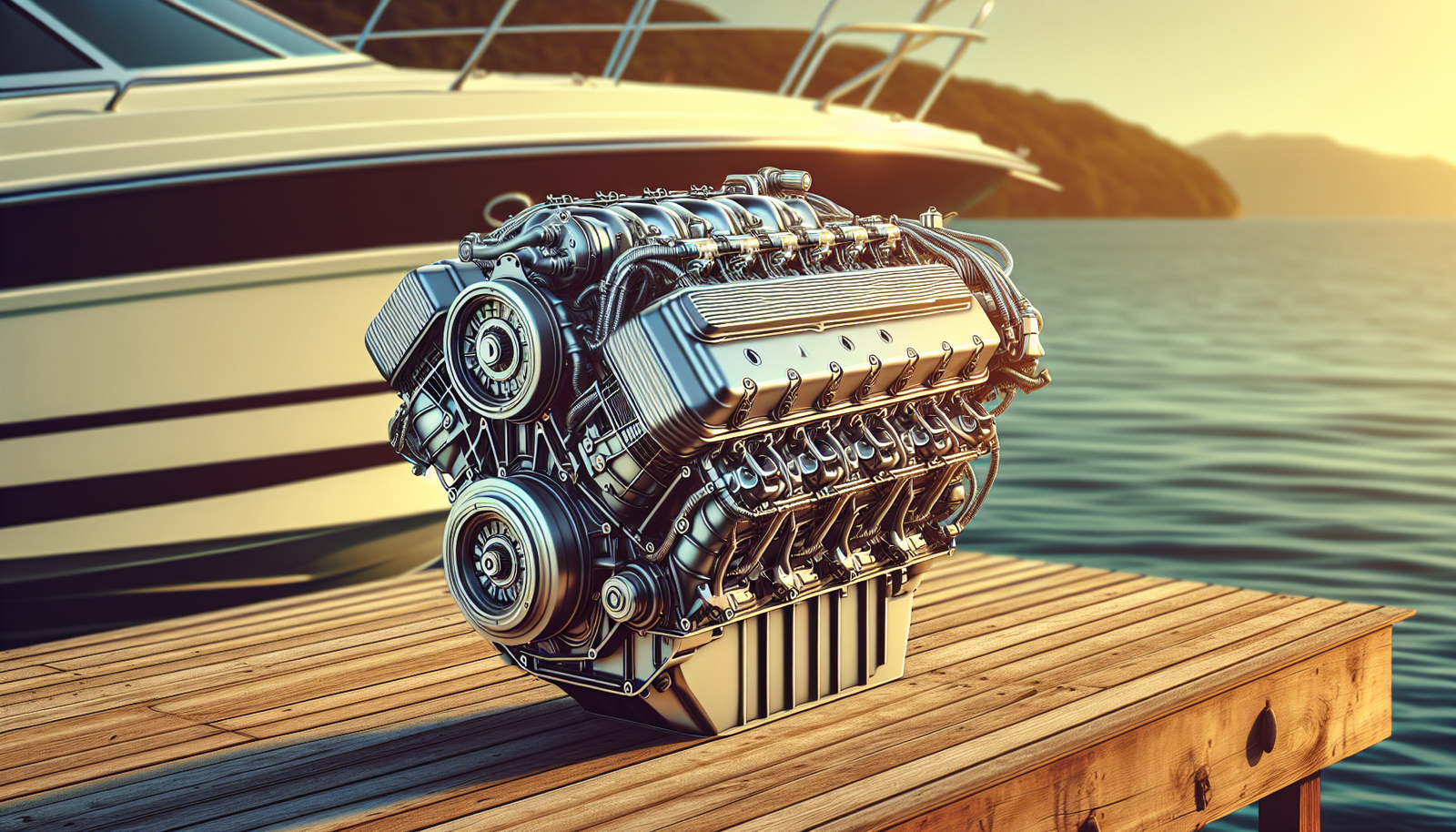

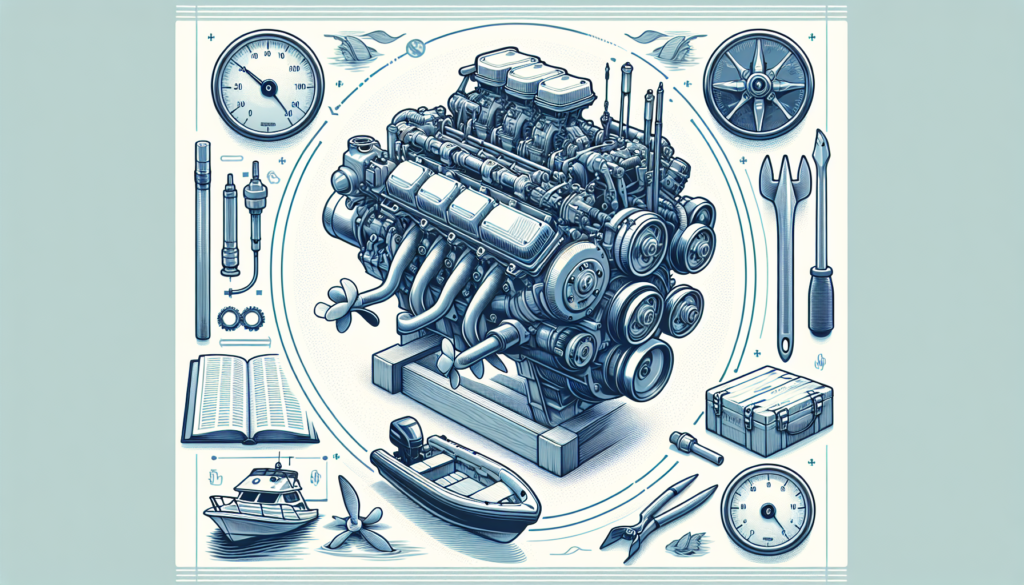

Getting Familiar with Your Boat Engine

Before you can successfully break in your engine, you need to be familiar with its components, type, and manufacturer’s guidelines.

Types of boat engines

There are primarily two types of boat engines – outboard and inboard. Outboard motors are mounted on the boat’s rear and contain the engine, gearbox, and propeller in one unit. In contrast, inboard engines are inside the boat, and the drive unit is separate. The break-in process may vary slightly based on the engine type.

Manufacturer’s guidelines and recommendations

It is essential to study the manufacturer’s manual thoroughly. The manual will guide you on various aspects like the break-in process, recommended fuel type, necessary precautions, and maintenance tips.

Key components of a boat engine

Familiarizing yourself with its key components like the propeller, carburetor, gearbox, and cooling system will get you ready for a successful break-in. With knowledge of these parts, you can better understand the engine’s functionality and monitor its performance during the break-in period.

Start-up Procedure for New Engines

Pre-startup checks

Before you start the engine for the first time, check the oil level and make sure the engine is properly lubricated. Also, look for loose wiring or parts. Ensure the cooling water inlet is not blocked and that the fuel tank is filled with the recommended fuel type.

Starting the engine for the first time

Now turn the ignition key to start the engine. Do not be alarmed if the engine doesn’t start immediately. It may take a few attempts to draw fuel into the engine.

What to observe during the initial start

Keep an ear out for unusual sounds and observe the engine for any signs of leaks. Also, check the exhaust for heavy or discolored smoke as it could indicate a problem.

Initial Operation and Precautions

Operating the engine at low speed

During the initial hours of operation, run your boat engine at the lower end of the RPM range. This slower pace helps let the moving parts seat properly and promotes better fuel efficiency in the long run.

Paying attention to engine sound and vibration

A properly functioning engine should run smoothly without any unusual sounds or excessive vibrations. If you notice anything peculiar, shut down the engine and investigate immediately.

Monitoring engine temperature and pressure

Keep a constant eye on the engine temperature. Overheating can cause significant damage. Similarly, monitoring oil pressure is equally important. Low oil pressure can indicate a lack of lubrication.

Varying the Engine Speed

Importance of alternating engine speed

Your engine shouldn’t be operated at a single, continuous speed during the break-in period, as it can lead to the premature wear of components. Alternating speeds allow all parts to be used and broken in evenly.

Recommended periods at each speed level

Your manufacturer’s manual will specify this, but a typical recommendation is to vary the throttle setting every 15 minutes.

Avoiding continuous same-speed operation

Operating in diverse conditions ensures the engine experiences different loads, which is necessary for an effective break-in.

Using the Correct Fuel and Oil

Recommended types of oil and fuel

First, adhere strictly to the oil and fuel recommendations in your boat engine’s manual. High-quality, correct specification oil and fuel are essential for your engine’s performance and longevity.

Effects of using low-quality fuel or oil

Low-quality fuel or oil can lead to engine problems like power loss, lower fuel economy, damage to the fuel system, increased wear, or even total engine failure.

When and how often to change the oil

The first oil change should be done after the break-in period. After that, regular oil changes, as per the manufacturer’s recommended schedule, are necessary for the engine’s proper functioning.

Monitoring and Adjusting the Cooling System

The role of the cooling system in breaking in

The cooling system plays a vital role in the break-in process. It keeps the engine temperature at an optimal range and prevents overheating, which could cause severe damage.

How to ensure effective cooling

Regular checks of the cooling system and keeping the water inlet clear of debris are critical for effective cooling.

Signs of problems in the cooling system

Watch out for reduced water flow from the tell-tale, overheating, or sudden loss of power. These could be signs of cooling system issues.

Regular Maintenance During Break-in Period

Checking the engine for leaks and loose parts

Regular inspections of the engine for leaks, loose parts, or other abnormalities are necessary throughout the break-in period.

Cleaning and replacing filters

Regularly cleaning air and fuel filters helps maintain optimal engine performance. Replacing all filters at the end of the break-in period is a good practice.

Regular inspections by a professional

Enlisting a marine professional’s help for routine inspections can ensure any potential issues are caught and addressed before becoming major problems.

Troubleshooting Common Problems

Common issues during the break-in period

The common problems during the break-in period can include overheating, excessive smoke, high oil consumption, vibrations, noise, or reduced engine performance.

How to address these problems

The best approach is to consult the manual or a professional. In most cases, it’s advisable not to attempt repairs without adequate knowledge.

When to seek professional help

If your engine is overheating continuously, leaking, making unusual sounds, or if you can’t identify a problem but realize something’s off, it’s time to seek professional help immediately.

Post Break-in Procedures

What changes after the break-in period

After the break-in period, your engine will be ready for normal operation. However, it still requires regular maintenance and care to ensure it continues to run at its peak.

Normal operating procedures for the engine

These will be specified in your manufacturer’s manual. They would include a wide range of RPM operations and regular maintenance.

Maintaining your engine for longevity

Keeping your engine clean, regular oil changes, cooling system checks, and sticking to the manufacturer’s maintenance schedule will ensure the longevity of your engine.

With an understanding of this guide, you should be well-prepared to break in your new boat engine. Remember, patience and care during this process can lead to many years of reliable and enjoyable boating experiences.