Boat enthusiasts and sea lovers alike will understand the importance of a well-maintained inboard engine – it’s the heart and soul of any leisure craft, fishing vessel, or speedboat. “Key Maintenance Tasks for Inboard Boat Engines” will guide you through the essential upkeep procedures to keep your engine running smoothly and most importantly, keep you safe on the water. Not only will you learn about the basics like oil checks and filter changes, you’ll also discover insider tricks of the trade to prolong the life of your engine without draining your wallet. Taking good care of your inboard engine has never been this straightforward.

Understanding Inboard Boat Engines

Boating can provide a great time on the water, especially when all parts of your vessel are running smoothly. One critical component of your watercraft is the inboard engine which powers the vessel.

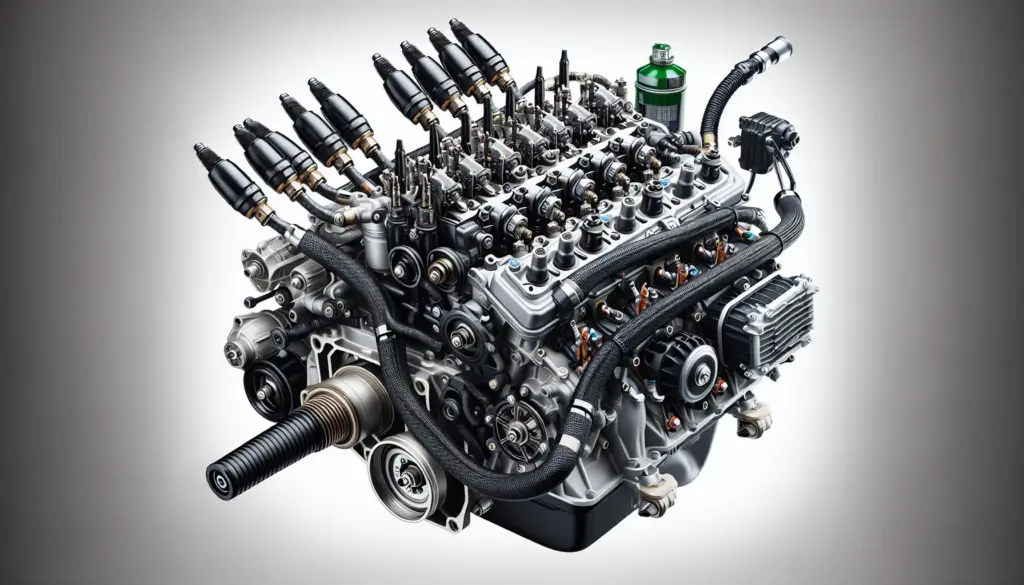

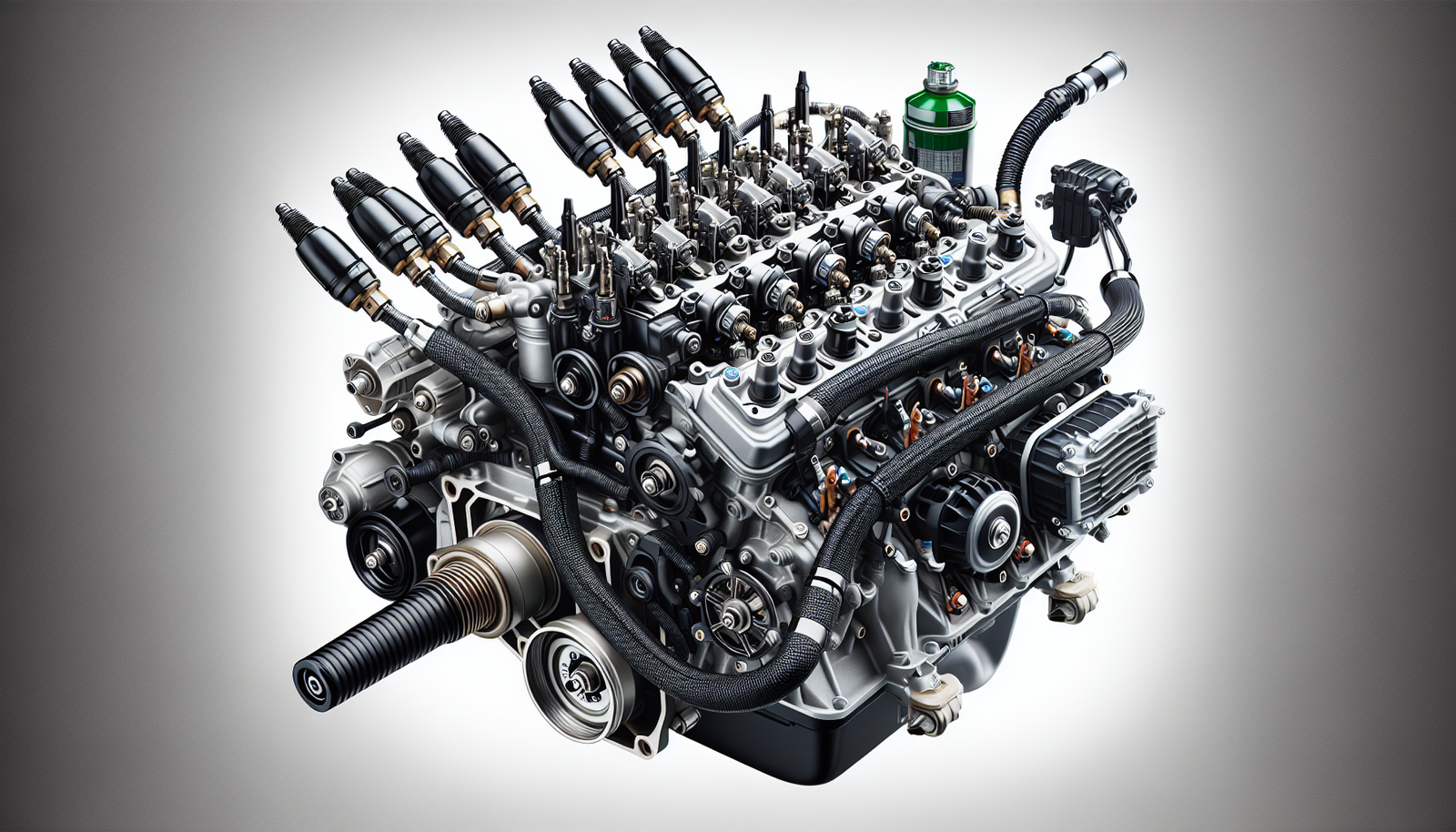

Types of inboard engines

There are a few types of inboard engines that you may find on a boat. The most common one would be a diesel engine, which is similar to a car’s engine, but with modifications to perform optimally on the water. Another type would be a gasoline engine which is pretty compact and offers a quite high power-to-weight ratio. Then, there are steam engines typically found on vintage or traditional boats.

Basic functioning of inboard engines

Inboard engines, like other engines, basically work on the principle of internal combustion. The engine turns the burning fuel’s vitality into mechanical power. It draws the fuel into the combustion chamber, where it mixes with air. Spark plugs ignite this air-fuel mixture, resulting in an explosion that pushes pistons. This motion is converted into rotational motion to turn the propeller and push the boat forward.

Difference between inboard and outboard engines

Inboard and outboard engines essentially share the same purpose – to power your boat, but their placement and design vary significantly. Inboard engines are installed inside the boat, towards the center, which offers better balance and stability. In contrast, outboard engines are attached to the stern externally, and they contain the engine, gearbox, and propeller in one unit.

Frequently Checking and Changing the Engine Oil

Maintaining and monitoring the engine oil of your inboard boat engine is a crucial part of its upkeep.

Importance of regular oil checks

Consistent oil checks are vital to keep your engine running smoothly. Oil helps in lubrication, cooling, and cleaning of the various components of the engine. Frequent oil checks ensure optimal engine performance and longevity.

Correct Procedure for changing engine oil

To change the oil, you first need to warm up the engine a little, so the oil drains out easily. Disconnect the fuel supply, and remove the oil via the drain plug or an oil extractor. Once the old oil is out, replace the oil filter and refill with new, clean oil.

Recommended oil types for inboard engines

The type of oil suitable for your engine would depend on the engine type and model. It is always best to follow the manufacturer’s recommendations when it comes to engine oil. Generally, for most inboard engines, multi-viscosity oils like 10W-30 or 15W-40 are recommended.

Regularly Checking and Cleaning The Fuel System

Another critical part of your boat’s engine involves monitoring and cleaning the fuel system.

Why fuel system maintenance is crucial

A well-maintained fuel system ensures your boat runs efficiently and prevents issues like engine failure because a clean fuel system gives you enhanced performance and fuel efficiency.

Signs of a clogged fuel system

Some signs of a clogged fuel system may include difficulty in starting the engine, inconsistent engine performance, poor fuel efficiency, or the engine not reaching its full speed.

Cleaning procedure for inboard engines fuel system

Typically, cleaning the fuel system involves adding a fuel additive that cleans and preserves the system. It is also essential regularly to replace fuel filters and ensure that the fuel system is free of any moisture.

Examining and Replacing Spark Plugs

Spark plugs play a crucial role in the functioning of inboard engines.

Role of spark plugs in engine functioning

Spark plugs provide the ignition necessary for the combustion of the fuel-air mixture in the engine. Without a properly functioning spark plug, the engine might not start or perform optimally.

Steps for examining spark plugs

You can examine spark plugs by first removing them from the engine. Look for any deposits or burns on the plug, which may indicate a problem. You can also check the gap between the electrodes using a gap tool.

Determining when to replace spark plugs

If the electrodes are worn out or the plug is covered in deposits, it may be time to replace them. However, even if they look fine, it is still advisable to replace spark plugs after every 100 hours of use or as suggested by your engine manufacturer.

Maintaining the Propeller

Your boat’s performance on water largely depends on the propeller’s condition.

Role of the propeller in boat operation

The propeller’s main function is to transfer the engine’s power into thrust, pushing the boat forward. Without a well-functioning propeller, the engine’s performance will not translate effectively into the boat’s movement.

Common propeller issues

Common propeller issues often involve physical damage like dents or bends which can impact the boat’s performance. There could also be issues of corrosion, especially for boats operating in salt water.

Effective ways to maintain and repair a propeller

Inspecting the propeller frequently for any physical damage or signs of wear is a good maintenance practice. Periodically cleaning and polishing the propeller can help prevent corrosion and fouling. In case of any damage, it may need to be repaired or replaced.

Cleaning and Protecting the Engine Exterior

keeping the exterior of your engine clean is equally important.

Significance of engine cleanliness

Cleaning the exterior part of the engine helps prevent corrosion and allows you to spot potential issues like leaks or damage early.

Correct cleaning procedure for inboard engines

Cleaning involves removing dust and debris from the engine’s exterior and carefully cleaning with a specific engine cleaner and a soft cloth. It is essential to avoid any electrical components while cleaning.

Best products for protecting engine exterior

Protecting the engine exterior usually involves applying a layer of rust inhibitor or anti-corrosion spray, which shields the components against damage from environmental elements.

Maintaining the Cooling System

A properly functioning cooling system is crucial for the engine’s performance and longevity.

Importance of a functional cooling system

The cooling system prevents the engine from overheating, which is critical for the engine’s lifespan and performance. A dysfunctional cooling system can lead to severe engine damage.

Identifying issues with the cooling system

Symptoms of cooling system issues can include the engine running hotter than normal or overheating, an unusual noise, or the presence of coolant leaks.

Maintenance steps for the cooling system

Regularly flushing the cooling system and filling it with fresh coolant, ensuring all connections and hoses are secure and in good condition, and frequently inspecting the water pump for any wear or damage are part of maintaining the cooling system.

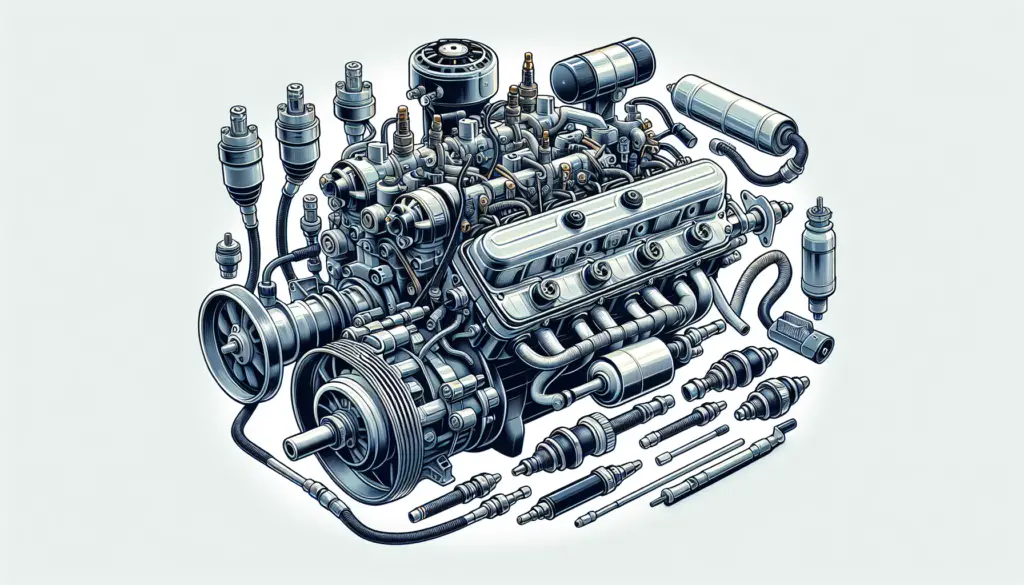

Inspecting and Replacing Drive Belts

Drive belts are another essential component of inboard engines.

Role of drive belts in inboard engines

Drive belts play a crucial role in powering the alternator, water pump, and other components. If a drive belt fails, it could lead to engine overheating and severe damage.

How to inspect drive belts

You can inspect drive belts for any signs of wear or damage, such as cracks, fraying, or slackness. Also, listen out for any strange noises when the engine is running, as it may suggest a belt issue.

When and how to replace drive belts

Belts should typically be replaced after about 100 hours of use or according to the manufacturer’s guidelines. To replace a belt, first, loosen the old belt by adjusting the alternator, and then slide the belt off. Replace it with a new one and retighten.

Winterizing the Inboard Engine

If you reside in places where temperatures drop significantly during the winter, it’s essential to winterize your inboard engine.

Why it’s necessary to winterize inboard engines

Winterizing involves preparing the engine to withstand freezing temperatures to prevent severe damage like cracking or corrosion that freezing conditions can cause.

Step by step guide to winterizing the inboard engines

Winterizing typically includes draining any water in the engine or cooling system, adding a fuel stabilizer, changing the oil and oil filters, and then storing the boat properly. It is also suggested to apply anti-corrosion spray and cover the engine.

Common mistakes to avoid when winterizing

Common mistakes to avoid include not changing the oil, not using a fuel stabilizer, and not correctly storing the boat. These practices could lead to rusting, engine damage, and degradation of fuel.

Periodic Professional Service

Though routine maintenance can be done by yourself, getting periodic professional service is highly recommended.

Benefits of professional inboard engine servicing

Professional service ensures thorough inspection and servicing of the engine. A professional can diagnose and fix issues that you might overlook and also offer crucial advice on engine maintenance.

When to seek professional help

You should seek professional help if you notice unusual noises, smoking, loss of engine power, or any other engine-related issues. A professional service annually or after a certain number of running hours is also beneficial.

Choosing a reputable servicing firm

It’s crucial to choose a reputable servicing firm with well-trained technicians familiar with the brand and type of your engine, providing quality service and original parts as per the manufacturer’s guidelines.

In conclusion, inboard boat engine maintenance may require some work, but with regular checks and appropriate care, you’ll ensure that your boat engine stays in top condition for many adventures to come.

[…] of engine you have in your boat will influence the kind of maintenance it requires. For example, inboard and outboard motors have their unique set of characteristics and components, which affects their maintenance […]