Get on board with your role as the can-do captain and discover the essential steps for routine boat engine maintenance. This article serves as the mariner’s compass to guide you through the process, helping you keep the heart of your vessel – the engine – in its prime condition. Tackling fundamentals such as engine inspection, cleaning, and fluid changes right down to troubleshooting common issues, we’ll chart out a smooth sailing route for efficient yacht upkeep. By mastering routine maintenance, you can ensure your choice steed of the sea remains shipshape, giving you that extra peace of mind while enjoying the open water.

Understanding the Importance of Regular Engine Maintenance

Listen, keeping your boat in shipshape is like taking care of your teeth, you’ve got to do it consistently if you want it to last. And that’s tall order if you consider all the parts that make your boat run smoothly. But there’s one component that stands head and shoulders above the rest: the engine. Your boat’s engine is like its beating heart, requiring ongoing care and attention.

Identifying common causes of boat engine problems

Like any piece of machinery, boat engines have their fair share of problems. Perhaps the most common issue revolves around fuel. Bad fuel, contaminated fuel, and fuel decay can all result in an engine that doesn’t start, or worse, damage your engine permanently. But it’s not just fuel. Neglecting regular oil and fluid changes, positions your engine on a slippery slope towards significant damage. Even inappropriate winter storage can be a culprit.

Types of engine damage to avoid

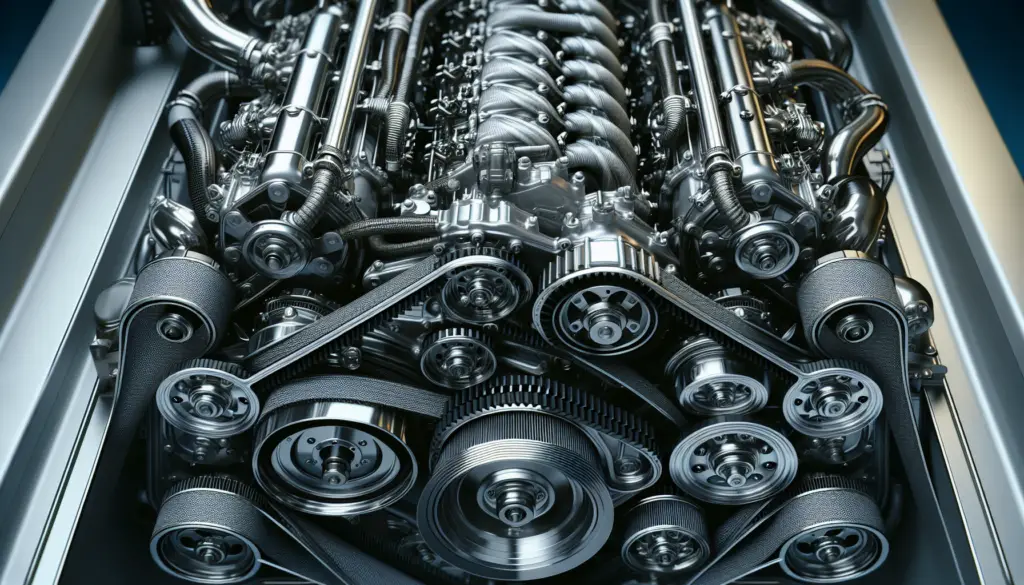

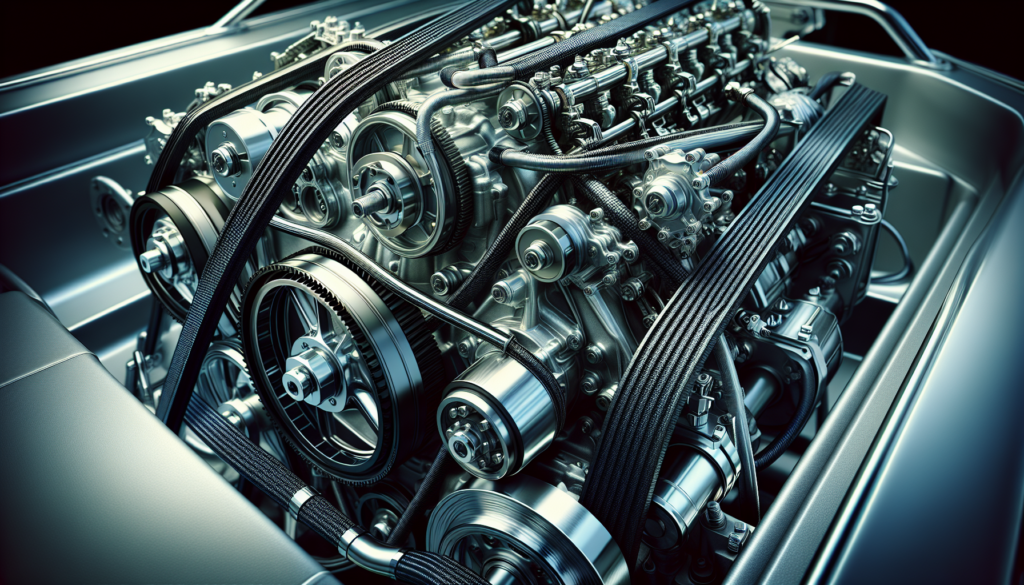

The types of engine damage you’re ideally looking to avoid fall into two main categories: internal and external. Internal damage includes wear and tear of the engine’s internal components while external damage pertains to parts like the alternator, starter, belts and hoses that can wear out over time. Keeping an eye out for such issues could save you from premature engine failure.

Impact of regular maintenance on engine lifespan

Here’s the bottom line: regular maintenance can greatly increase the lifespan of your engine. It’s like going for regular doctor check-ups. The earlier you catch a problem, the easier it is to fix, averting you from more serious issues down the line.

General Inspection of the Engine

Observing the outer condition for any visible issues

Your first line of defense when tending to your engine involves just looking it over. Easy peasy, right? You’re hunting for obvious issues like leaks, rust, or cracks.

Checking the engine for any noises

Your ears can be as mighty as your eyes when observing your engine. Strange noises could be your engine crying out for help. Like high-pitched squeals, which might indicate a problem with the belts or bearings.

Examining engine parts for wear and tear

Getting up close and personal with your engine can unearth issues that aren’t visibly apparent. Think of this step as giving your engine a physical examination.

Maintaining the Fuel System

Checking the fuel lines regularly

Your fuel lines are your engine’s feeding tubes, regularly checking them for leaks, cracks or bulges can prevent a host of issues down the line.

Replacing the fuel filter

A clogged or dirty fuel filter can starve your engine of fuel. Regular inspection and replacement, as per your manufacturer’s recommendation, is key.

Cleaning the fuel tank to avoid contamination

Your fuel tank can become a breeding ground for bacteria and fungi, which can contaminate your fuel system and cause havoc to your engine.

Oil and Lubricant Changes

Checking oil levels regularly

Like checking the gas meter in your car, it’s essential to regularly check your engine oil levels. Low or dirty oil can ruin your engine’s internal components.

Changing the engine oil as per manufacturer recommendations

Changing your engine oil is like giving it a new lease on life. Over time, oil breaks down and becomes less effective, but fresh oil can keep your engine running smoothly.

Application of lubricants to necessary parts

Using lubricants on key engine parts reduces friction and minimizes wear and tear on your engine components.

Checking the Cooling System

Inspecting for clogs in the cooling system

A blocked cooling system can lead to engine overheating. Regular inspection can go a long way in identifying obstructions.

Ensuring the flow of cooling water is uninterrupted

An uninterrupted flow of cooling water is vital for maintaining your engine’s operating temperature.

Replacing the cooling fluid if necessary

At times, your engine’s coolant might need to be replaced to keep your engine from overheating.

Battery Maintenance

Regular battery cleaning

Battery terminals corrode over time, affecting their ability to power your engine. Regular cleaning can keep this issue at bay.

Ensuring secure connections

Loose battery connections can lead to an engine that won’t start. A quick jiggle to ensure everything’s tightly connected can save you headaches down the road.

Battery replacement if necessary

Every battery has an expiry date, and replacing it when necessary can prevent unanticipated engine power loss.

Taking Care of Belts and Hoses

Inspection for cracks or damage

Belts and hoses can develop cracks or weaken over time, leading to leaks or breakages. Regular inspections can help find these issues early on.

Checking belts tension

Having the correct tension in your engine’s belts is crucial for smooth operation. Too loose or too tight can cause serious engine damage.

Keeping replacements onboard if necessary

Having spare belts and hoses onboard prepares you for unexpected breakages and can save your engine from serious damage.

Maintaining the Propeller

Regular inspection for dents or distortion

Your propeller is your engine’s driving force. Dents or distortions could lead to uneven running and wear of your engine components.

Ensuring the propeller is securely attached

A loose propeller could wreak havoc on your boat’s operation and potentially damage your boat’s gearbox.

Lubricating the propeller shaft

Like any moving part, your propeller shaft needs lubrication to prevent overheating and wear.

Keeping an Eye on the Electrical System

Looking for corrosion or damaged wires

Damaged wires or corrosion can disrupt the electrical flow to your engine. Regular inspections can ensure your engine’s electrical system is in top shape.

Checking for loose or disconnected wires

Loose or disconnected wires can cause intermittent engine problems. Regular wire checks can save you unexpected engine shutdowns.

Replacing parts if necessary

Wear and tear can necessitate replacements. Swift action at times like these could save you more significant problems down the road.

Winterizing Your Boat Engine

Draining the engine to prevent freezing

Failing to drain your engine can lead to freezing and subsequent engine damage. It’s an essential step in winterizing your engine.

Protective coating for corrosion prevention

Applying a protective coating can protect your engine from corrosion during winter storage. A simple solution to ensure your engine roars back to life when boating season returns.

Battery storage during winter

Winter can be hard on your battery. Removing it from your boat and storing it someplace warm can help keep it in good shape.

So, there you have it! Stick religiously to these steps, and I bet your engine will purr like a kitten every time you take it out!