As you anticipate the thrill of the upcoming boating season, ensuring the readiness of your watercraft’s engine is probably top of mind. The piece, “The Ultimate Checklist For Preparing Your Boat Engine For The Boating Season” provides a meticulous guide that will arm you with the essential steps to take. You will learn how to give your boat’s heart – its engine, a thorough examination. From its cooling systems, fuel system, ignition components, to battery health, you’ll get the knowledge necessary to prepare your boat for the unforgettable water adventures that lie ahead. So, gear up to navigate through this engaging, informative journey of boat engine preparation.

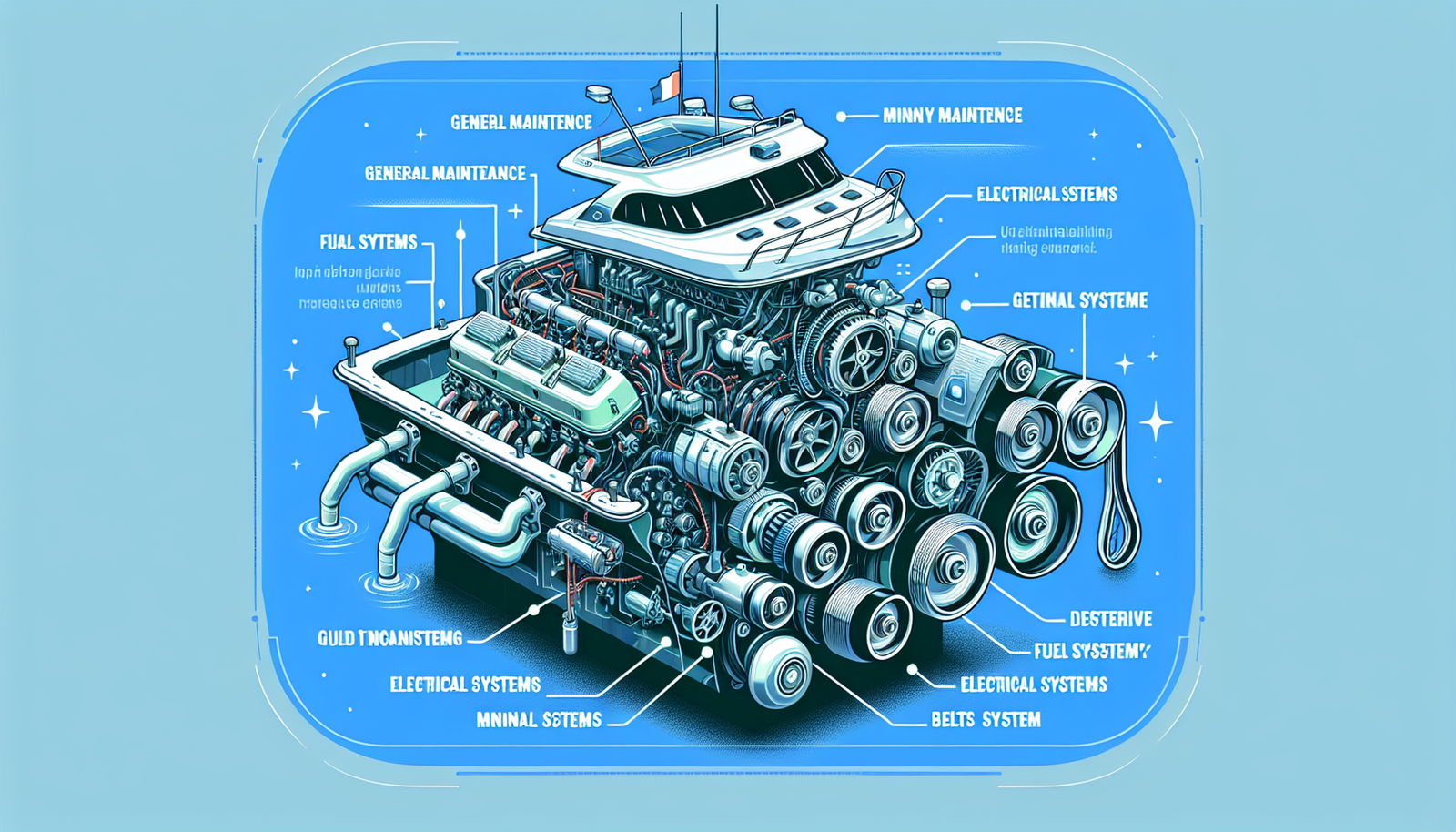

Understanding the Basics of Boat Engine Maintenance

Whether you’re a thrill-seeker navigating tumultuous waves or you prefer a leisurely cruise on a calm lake, owning a boat adds a plethora of exciting hobbies to your life. However, along with the fun and excitement that boats bring, they also carry the responsibility of proper and regular maintenance. This is particularly true for your boat’s engine, which acts as its heart.

Principles of boat engine upkeep

The importance of boat engine maintenance cannot be overemphasized. It involves several key principles such as regular examination for possible leaks, monitoring and authentication of all mechanical elements, oil changes, and overall cleaning. Staying diligent with these principles helps to avert mechanical mishaps and ensure smooth operation.

Understanding different kinds of boat engines

In order to conduct proper maintenance, it’s crucial to understand the types of boat engines. Broadly, they are classified into two main categories: inboard and outboard engines. Inboard engines, much like car engines, are located inside the hull, while outboard engines sit outside the hull. The type of engine determines the specific maintenance activities to be undertaken.

Significance of regular boat engine maintenance

Aside from extending the life of your boat’s engine, regular maintenance also helps to prevent potential breakdowns which can compromise your safety. Maintenance ensures your engine is running at its utmost efficiency, optimizes fuel consumption, and reduces the risk of engine failures.

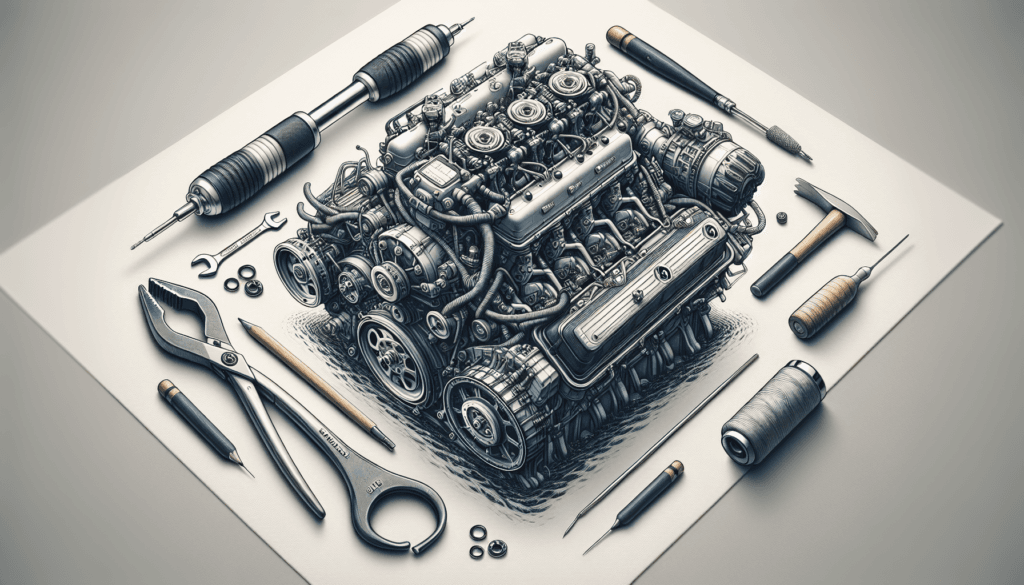

Tools and Equipment Needed for Boat Engine Maintenance

While boat engines are intricate, maintaining them on your own isn’t an impossible task, especially when you have the right tools.

Essential boat maintenance tools

For basic boat engine maintenance, you’ll need various wrenches, screwdrivers, pliers, a digital multimeter for electrical testing, and a marine grease gun for lubrication tasks. You should also have a flashlight to illuminate dark areas during inspection.

Safety equipment for boat engine maintenance

Safety should always be your top priority during engine maintenance. Be sure to have a fire extinguisher, eye protection, gloves, and a first aid kit at hand when conducting maintenance operations.

Proper use and handling of tools and equipment

It’s not enough to simply possess these tools and equipment—a sound knowledge of their proper handling is essential. Misusing these tools can lead to damage and possible engine malfunctions. Always use the right tool for the specific task and keep your working premises clean and organized.

Checking the Fuel System

The fuel system forms the backbone of your boat’s performance, powering the engine that gets you moving.

Inspecting the fuel tank

Check the fuel tank for any indications of rust, leakage or damage. Ensure the tank’s surface is free from dents or scratches, paying extra attention to connections and lines.

Checking the fuel filters

Clogged or dirty fuel filters can interfere with your engine’s performance. Regularly inspect, clean, and replace these filters as per manufacturer’s guidelines to allow optimal fuel flow.

Ensuring proper fuel lines

Inspect your fuel lines regularly for signs of wear and tear, such as cracking or hardening. Your fuel lines should be flexible—any rigidity might hint at potential failure.

Inspection of the Boat’s Engine Oil

Being the lifeblood of your engine, keeping tabs on the oil is crucial for a healthy boat journey.

Signs of oil leakage

Regularly inspect your engine compartment for signs of oil leakage. If you notice any accumulation of oil or an unusual oily smell, there could be a leakage problem that needs prompt attention.

Checking oil levels and quality

The engine oil level must be checked every time before you start the boat. Use a dipstick to measure your engine oil level, ensuring it falls within the recommended limits. The oil should be clear and free from impurities.

Replacing the boat’s engine oil

Depending on use, oil should be replaced after every 50-100 operating hours as per manufacturer’s specifications. Old and degraded oil can cause engine parts to wear prematurely, hence timely oil replacement is crucial.

Examination of Belts and Hoses

These play a critical role to ensure all the engine components work synchronously and efficiently.

Inspecting the condition of belts

Examine all belts for tension, wear and tear. Loose belts can cause inefficient operation, and worn out belts can break, resulting in considerable damage.

Checking the state of hoses

Hoses should also be inspected for any signs of cracking, bulging or leaking. If you notice any unusual hardness or brittleness, it’s time to consider a replacement.

Understanding the role of belts and hoses in boat engines

Belts and hoses are vital because they connect and power crucial aspects of your boat’s engine. Belts turn the alternator, water pump, and other engine components, while hoses transport fluids.

Assessing the Cooling System

Preventing the engine from overheating is crucial to ensure its longevity and reliable operation.

Identifying issues with the cooling system

Issues with the cooling system often manifest as an overheating engine. Regularly check the coolant level and inspect the hoses and connections for leaks or blockage.

Regular maintenance for the cooling system

Carry out regular maintenance by flushing out the cooling system and refilling it with the correct percentage of coolant as recommended by the manufacturer.

Replacing parts of the cooling system if necessary

If upon inspection you discover a component of the cooling system is damaged, it’s advisable to replace it immediately to prevent overheating.

Maintaining the Propeller

The propeller is a vital part of your boat and needs careful attention.

Inspection of the propeller

Regularly inspect your propeller for any nicks, cuts or damages which can affect its performance. Additionally, check the security of your propeller by attempting to wiggle it—a loose propeller may lead to significant issues.

Cleaning and regular upkeep of the propeller

Ensure the propeller is clean and clear of any debris. Regular maintenance, such as greasing the propeller shaft, is essential to reduce friction and facilitate smooth operation.

Understanding the effects of a damaged propeller

Apart from decreased performance and speed, a damaged propeller can also cause vibration leading to wear and tear on the bearings and gear system.

Caring for the Boat Battery

No engine starts without a good battery—you guessed it, routine upkeep is necessary here too.

Checking the battery’s condition

Regularly inspect your battery for any leaks, cracks or bulges. A volt test can also tell you whether your battery is holding a charge or not.

Tips for battery upkeep

Keep your battery clean and corrosion-free. Also, ensure that it’s properly charged—both overcharging and undercharging can damage the battery.

When to replace the boat’s battery

Typically, a boat battery lasts 3 to 5 years. However, prolonged storage, frequent discharging, or poor maintenance can reduce its lifespan.

Evaluating the Bilge Pump

The bilge pump plays an often underrated, yet crucial role in your boat’s functionality and safety.

Understanding the importance of the bilge pump

The bilge pump’s job is to remove unwanted water from the bilges (lowest part inside the boat). Without it, water can accumulate in the boat, potentially causing damage or even sinking the vessel.

Maintenance checks for the bilge pump

Regularly inspect the bilge pump for any debris blocking its operation. Ensure it’s in good shape by conducting routine tests.

Dealing with bilge pump problems

If your bilge pump is not effectively removing water or is making unusual sounds, it might indicate a mechanical problem and should be checked by a professional.

Keeping an Eye on The Boat’s Transmission System

This is what channels power from your engine and controls your boat’s speed and direction.

Inspecting the boat’s transmission fluid

Your transmission fluid should be replaced as per the manufacturer’s instructions. Regularly check the fluid level and color—dark or foul-smelling fluid might indicate a problem.

Checking the status of the transmission system

Regularly check the transmission system for any unusual noise or vibration. Also, be aware of any difficulties in shifting gears, as these signs may indicate issues within the transmission system.

Interrupting common transmission problems

If you notice any problem with your boat’s transmission, it’s advisable to get it checked by a professional immediately. Early detection and repairs can prevent the problem from escalating further, saving you time and money in the long run.

In conclusion, boat engine maintenance is crucial towards ensuring the longevity and performance of your boat. Though it may seem like a big task, with the right tools, plenty of patience, and regular scheduled checks, maintaining your boat engine can be a smooth-sailing task. Enjoy the water, and may your boat always be your pleasant sea companion!