Setting off for a significant journey on your boat soon? Brace yourself—the open waters are not as forgiving as you might think. This Ultimate Checklist For Servicing Your Boat Engine Before A Big Trip is your guide to ensure your journey is smooth sailing all the way. It’s a comprehensive walk-through that will assist you in keeping your boat’s engine in stellar condition. Think engine oil checks, coolant examination, and more—you’ll discover all the critical aspects that require your attention to avoid any breakdowns or mishaps during your voyage. It’s not just about prepping for your trip; it’s about ensuring your boat remains performing optimally for many more expeditions to come.

Understanding your Boat Engine

Boat engine maintenance is not just important, it’s crucial. Your vessel’s engine is the heart of your boat and understanding it will not only help you to keep it in tip-top shape but will also save you from unexpected and costly repairs.

Know the type of your engine

You can’t begin to maintain an engine if you don’t know what type it is. Boat engines can be broadly categorized into two: inboard and outboard. Inboard engines, which are placed inside the boat, are typically more powerful and are commonly found on larger vessels. Outboard engines are mounted outside the hull, usually on the stern, and are simpler to maintain as they are more accessible. Understanding the specifics of your engine type is the first step in properly maintaining it.

Identify the unique needs of your engine

Each engine type has its own unique needs and requirements. Diesels, for example, require very different care and attention than petrol or steam engines. Some engines might be water-cooled and others air-cooled. So, it’s vitally important to understand these specific needs when it comes to maintenance, as neglecting them can severely decrease the lifespan of your engine.

Familiarize with the engine’s parts and functions

Being familiar with the various parts of your engine, and their functions, can help you better understand when something isn’t quite right. Understanding the workings of your carburetor, fuel pump, spark plugs, and other essential parts can save you time and money by allowing you to troubleshoot and fix minor issues before they turn into major problems.

Checking the Oil Levels

Oil keeps the engine running smoothly by reducing friction, so it is important to check and change it regularly.

Identify the correct type of oil

Know your oil. 4-stroke engines typically require a 10w-40 oil, while 2-stroke engines use a specific 2-stroke oil. Using the wrong type of oil can damage the engine.

Check oil levels

It’s also important to check the oil levels regularly, as an engine that’s low on oil will have increased friction and can quickly overheat.

Change the oil if needed

Changing the oil is a regular maintenance task. Most manufacturers recommend changing the oil every 100 hours of engine operation, or at least once a year.

Inspecting the Fuel System

Your fuel system needs to be in good working order to ensure your engine runs smoothly.

Inspect the fuel tank

Regularly inspect your fuel tank for any signs of damage, leaks, or contamination. This could include dirt, water, or other foreign material which could clog fuel lines or damage the engine.

Check for leaks

A fuel leak is a serious potential fire hazard and can lead to a loss of engine power. Check all the connections, hoses, and seals in the fuel system.

Replace the fuel filter

The fuel filter removes any contaminants in the oil. Over time, the filter can become clogged and need replacing.

Fill up the tank with fresh fuel

Always fill up with fresh fuel before your voyage. Over time, fuel can degrade, which can lead to poor engine performance.

Checking the Cooling System

The cooling system maintains the engine’s optimal temperature, allowing it to run efficiently.

Ensure coolant is at the right level

This means making sure you have enough coolant in your system. If levels are low, top it up with a mix of coolant and water.

Inspect for leaks

Leaks in the cooling system can lead to engine overheating. Inspect the coolant reservoir and all corresponding hoses for any signs of leaks.

Check the condition of the hoses

Hoses should be secure with no signs of wear or damage. If they’re old or cracked, it’s time to replace them.

Clean the cooling system

Keeping the cooling system clean helps to prevent blockages and ensure it runs efficiently. You can do this by flushing the system with coolant cleaner and water.

Inspecting the Belts and Hoses

Belts and hoses are simple parts of the engine, but their failure can lead to serious engine problems.

Check for signs of wear and tear

Regularly check your belts and hoses for any signs of wear and tear, such as cracks, tears, or fraying.

Ensure connections are secure

Make sure that all belts and hoses are properly connected. Loose connections can hinder engine performance and cause damage.

Replace as necessary

Once you find a defective belt or hose, replace it immediately. Always keep spares on hand for quick replacements.

Cleaning and Lubricating

Keeping your engine clean and well-lubricated can extend its lifespan significantly.

Clean the exterior of the engine

Routinely clean the engine exterior to prevent build-up of dirt, salt, and other potentially harmful substances.

Ensure engine is properly lubricated

Proper lubrication of movable parts decreases friction, reducing wear and tear on the engine.

Inspect and clean the propeller

The propeller should be inspected regularly for dents, cracks or distortion. Regular cleaning can prevent build-up of dirt and marine growth that can affect its performance.

Reviewing the Ignition System

The ignition system initiates the engine’s operation and its components need regular inspection.

Check the spark plugs

Spark plugs are integral to the ignition process. Check for any signs of corrosion, cracks, or wear.

Inspect the distributor cap and rotor

Both serve to distribute voltage from the ignition coil to the spark plug. Look for any signs of wear or damage.

Review wires for any damages

Check all wires for any cracks, loose connections, or corrosion that might impede electricity flow.

Testing the Engine’s Electrical System

The electrical system powers not just the engine, but also the lights, GPS, radio, and other onboard electronics.

Examine battery health

Regularly check the battery’s voltage and its terminals for signs of corrosion. Ensure it is securely mounted and connections are tight.

Check the voltage reading

An engine’s electrical system should produce a voltage reading between 13.6 and 14.3 volts. Any higher or lower indicates a probable issue.

Inspect lighting and wiring systems

Check all onboard lighting and wiring systems for signs of wear, damage or corrosion. Replace bulbs and faulty wiring as necessary.

Checking the Boat’s Exhaust System

Exhaust systems remove the byproducts of combustion. A clogged or leaking exhaust system can inhibit engine function or even lead to engine failure.

Inspect exhaust manifolds

These collect exhaust from the engine. Make sure they’re not blocked or corroded, as this can cause poor engine performance.

Look for any signs of corrosion

Corrosion can cause the exhaust system to leak, which can be harmful and damaging to the engine.

Examine water injection system

This is used to cool exhaust gases. Check that the water is being properly injected to prevent overheating of the exhaust system.

Final Precautions

Lastly, but importantly, always be prepared for sudden unforeseen engine problems.

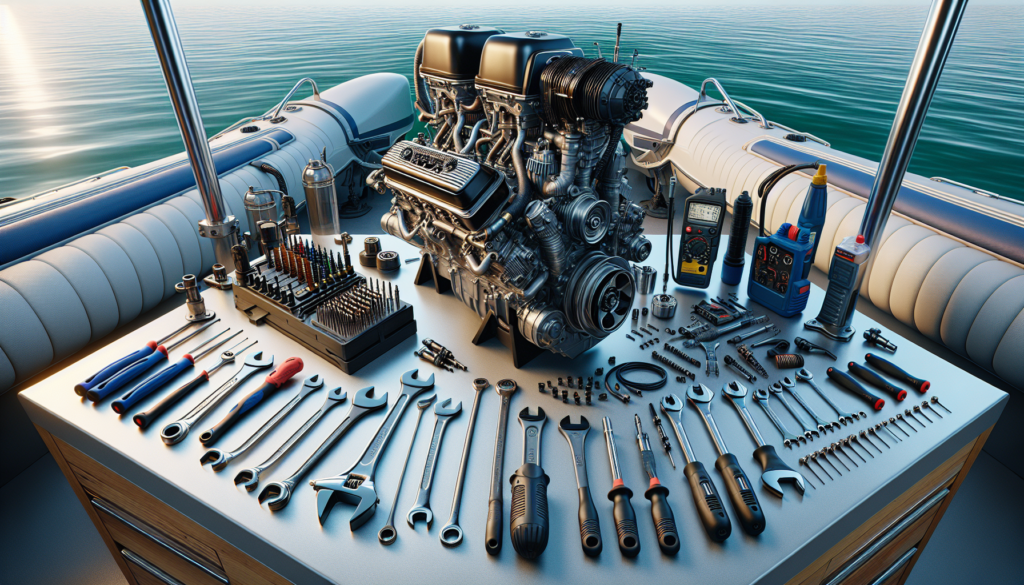

Have a boat repair kit handy

This should include common engine parts, tools, and basic supplies.

Keep spare parts and essential tools

Keeping spare parts like filters, belts, bulbs, plugs, and fuses on hand can make a huge difference in quickly fixing a problem.

Check weather conditions before venturing

Bad weather conditions can put undue strain on all parts of the boat, including the engine. Checking the weather conditions before you go out on the water will help ensure everyone’s safety.