Ever found yourself stranded in the middle of a beautiful lake because your boat engine decided to take an unexpected break? Nothing can ruin a day of boating faster than an engine failure. Your rescue lies in the precedingly mentioned article, “Top Boat Engine Breakdown Prevention Tips Every Boater Should Know.” Here, you will find invaluable insights on how to maintain your boat’s engine, keep it humming smoothly, and most importantly, prevent those unscheduled pit stops. Equip yourself with practical knowledge gleaned from experts and frequent boaters to ensure your maritime journeys remain uninterrupted and your vessel’s engine stays in prime condition.

Understanding Boat Engines

Boat engines are an indispensable part of your boating life. But do you really understand how they work, their key components, and the types of engines available? It’s like learning to drive—you don’t necessarily have to be a master mechanic, but having a solid grasp of the basics can really come in handy.

Types of Boat Engines

Boat engines can be differentiated on the basis of their working process, construction, and placement. The three main types of boat engines are inboard engines, outboard engines, and stern drives. Inboard engines are located inside the boat and are typically used in speed boats and fishing boats. Outboard engines are the most common type and they hang off the back of the boat. Stern drives, on the other hand, combine elements of both, and they’re usually found on larger, more luxurious boats.

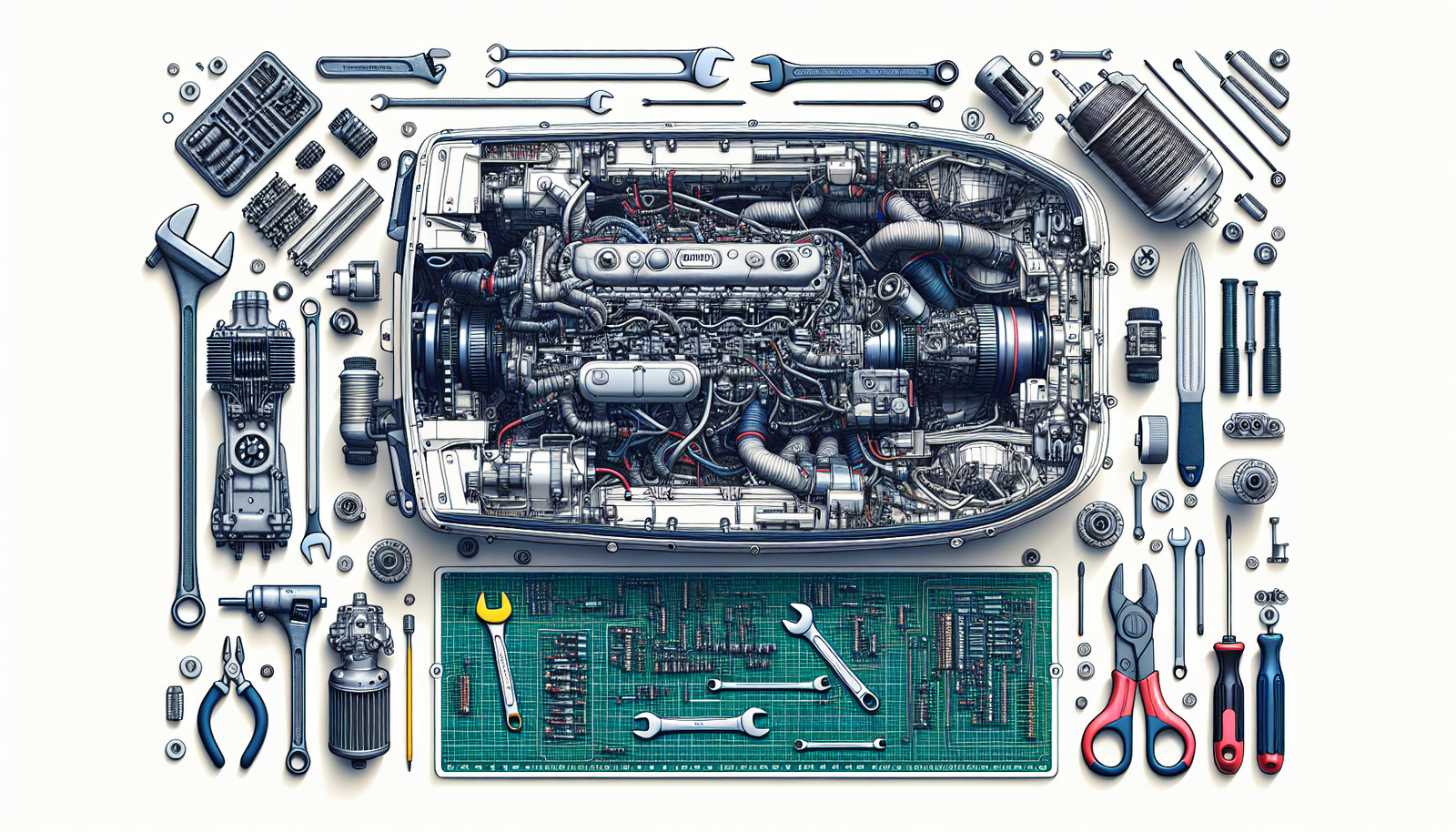

Main Parts of a Boat Engine

A boat engine consists of several components, but the main ones are the engine block, propeller, and the driveshaft. The engine block, containing pistons and cylinders, is where combustion happens. The driveshaft connects the engine to the propeller, and when the engine fires, it turns the driveshaft which, in turn, spins the propeller to propel the boat in water.

Working Mechanism of Boat Engines

The working mechanism of a boat engine is pretty similar to a car engine. Fuel and air mix together in the engine’s cylinders, this mixture is then ignited, and the resulting explosion pushes the pistons, which rotates the crankshaft and ultimately spins the propeller.

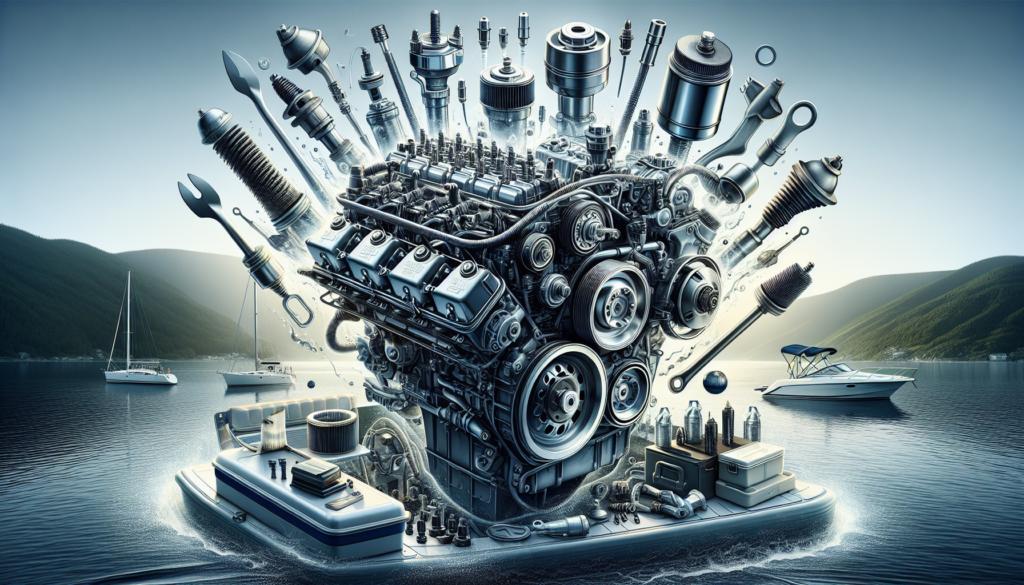

Regular Maintenance of Boat Engine

Regular maintenance of your boat engine not only ensures smooth running but can also prevent expensive repairs down the line.

Importance of Regular Maintenance

Regular maintenance helps to identify and address minor issues before they become major problems. It also ensures optimal performance and fuel efficiency, prolongs the life of the engine, and prevents unexpected breakdowns when you’re out on the water.

Elements of Maintenance Procedure

Key elements of the maintenance procedure include checking and changing the oil, inspecting the fuel system, checking the engine’s cooling system, inspecting and maintaining the battery, checking the propeller, and proper lubrication of engine parts.

Maintenance Intervals

There’s no one-size-fits-all answer to how frequently you should perform engine maintenance, as it depends on the type of engine, the age of the engine, how often you use your boat, and the conditions in which it’s used. That said, it’s a good idea to check crucial elements like oil and coolant levels before every trip, and to conduct a comprehensive check at least once a year.

Proper Boat Engine Winterization

Winterization is another crucial aspect of engine care. It protects your engine during the prolonged period of inactivity during the colder months.

Why Winterization Is Necessary

Cold temperatures can lead to damaging effects such as the freezing and cracking of the engine block and the corrosion of parts. Proper winterization protects against these and ensures your engine is ready to go when you’re ready to use your boat again.

Steps of Proper Winterization

Winterization involves draining the engine of fuel, changing the oil, flushing the cooling system and filling it up with antifreeze, removing and charging the battery, and properly storing the boat.

Things to Avoid During Winterization

Avoid leaving any water in the engine or the bilges, as it can freeze, expand, and cause damage. Ensure you use the correct type of antifreeze for marine engines, and don’t neglect the battery—you don’t want a dead battery come springtime.

Fuel System Care

A clean and functioning fuel system is essential for the health of your engine.

Importance of Fuel System Maintenance

Regular cleaning and maintenance of the fuel system can prevent issues like contaminant build-up, corrosion, blockages, and leaks, all of which could lead to reduced performance, damage to the engine, or even a breakdown on the water.

Steps for Keeping Fuel System Clean

Keeping your fuel system clean involves regularly draining and cleaning the fuel tank, inspecting fuel lines, and changing the fuel filter. It’s also important to use fresh, clean fuel and to use stabilizers if you’re storing the boat for a while.

Dealing with Water in the Fuel

Water in the fuel system can lead to issues like engine misfire, sputtering, and damage to the fuel pump and injectors. If you suspect water contamination, drain the fuel tank, replace the fuel filter, and refill the tank with fresh fuel.

Engine Oil Change and Top-Up

Like a car, your boat’s engine also depends on oil to keep it functioning smoothly.

Right Time for Oil Change

It’s recommended to change your engine oil every 50-100 hours of operation, or at least once a year. It’s also a good idea to change the oil before winter storage.

Choosing the Right Engine Oil

The right engine oil depends on the type of engine, the manufacturer’s recommendations, and the conditions in which you use your boat. Make sure you choose a high-quality marine engine oil, and avoid using automotive oil in your boat engine.

Procedure for Oil Change

Changing the oil involves draining the old oil, replacing the oil filter, and adding new oil. It’s a good idea to run the engine for a few minutes beforehand, as warm oil is easier to drain.

Proper Lubrication of Engine Parts

Lubrication reduces friction, prolongs the life of parts, and prevents rust and corrosion.

Identifying Parts That Require Lubrication

The main parts that require lubrication are the gears, linkage connections, moving parts, and fittings. Always refer to your engine’s owner’s manual for specific guidance.

Choosing the Right Lubricant

Using a good-quality marine-grade grease is essential, as it’s specifically designed to resist water washout and high pressures.

Lubrication Process

The lubrication process usually involves cleaning the area, using a grease gun to apply the lubricant, and manually working it in. Once you’re done, remember to wipe away any excess grease to deter dust and debris from sticking.

Cooling System Check

The cooling system prevents engine overheating, so it’s crucial to ensure it’s working correctly.

Understanding the Boat Cooling System

Boat engines usually use a water-cooling system, either raw water (drawing water from the surroundings as it goes) or closed-loop (using coolant).

Regular Inspection and Maintenance of Cooling System

This involves checking coolant levels, inspecting the water pump and hoses for leaks, and checking the heat exchanger and risers. Ringed anodes should also be replaced annually to prevent corrosion.

Dealing with cooling system issues

If your engine is overheating, check the water intake for blockages, make sure you have enough coolant, and inspect the water pump and thermostat. If you can’t find and fix the issue, it’s best to call in a professional.

Propeller Inspection and Maintenance

The propeller is what propels your boat forward and is a critical part of your engine.

Role of Propeller in a Boat Engine

The energy from the engine is transferred to the propeller, which uses this energy to create a thrust and move the boat forward.

Regular Inspection of the Propeller

You should regularly inspect your propeller for any signs of damage such as dings, pitting, and bends. Even minor damage can affect your boat’s performance and create vibrations that could damage your engine.

Maintenance and Cleaning of the Propeller

Regular cleaning with soapy water can remove growth and build-up. If there’s major damage, your propeller may need to be professionally repaired or replaced.

Battery Check and Maintenance

Your engine’s battery is what powers your boat’s electrical system.

Checking the Boat Engine Battery

Regularly check your battery’s charge level and look for signs of damage or corrosion. Also, make sure connections are tight and clean.

Maintenance of Boat Engine Battery

Clean the battery terminals, tighten loose connections, and top up the water level (if your battery requires it). Also, remember to recharge it if it’s low.

Replacing the Boat Engine Battery

If your battery is struggling to hold a charge or if it’s showing signs of damage, it may be time to replace it. Always replace it with a marine-grade battery.

Professional Diagnosis and Repair

Sometimes, despite your best efforts, you may need professional help.

When to Seek Professional Help

If you’re unable to identify or fix the problem, if your engine is still under warranty, or if it’s a complex issue that’s beyond your skills, it’s best to call in a professional.

Finding a Reliable Boat Engine Repair Service

Look for a service that has good reviews and a solid reputation. Also, find a service that specialises in your type of engine.

Costs and Duration of Repair Services

Costs and duration vary depending on the issue and the repair service. Some services offer emergency or quick-turnaround services, which can be pricier but faster. Remember, it’s usually worth the cost to get your engine running correctly and safely.