Living near the sea and owning a boat can be a life full of pleasant adventures or a series of costly troubles. It all depends on how well you maintain your boat’s engine which is always under the assault of harsh saltwater conditions. The article “Top Boat Engine Maintenance Tips for Saltwater Use” provides you with practical tips on how to keep your craft shipshape and ensure your boat’s engine enjoys a long and happy life at sea. Through this informative piece, you’ll learn not just how to clean and care for your boat’s engine, but also how to avoid preventable damage and costly repair jobs.

Understanding the Impact of Saltwater on Boat Engines

Saltwater is known for causing significant wear and tear to boat engines, unlike freshwater. Saltwater corrosion can seriously damage your boat’s engine and cause mechanical failures if steps are not taken to prevent it. It’s vital for you to understand the effects of saltwater corrosion so you can safeguard your boat’s engine health and prolong its lifespan.

Causes and effects of saltwater corrosion

Saltwater corrosion occurs due to the chemical reaction between metal, oxygen and salty water. It results in rusting and a continuous decay of the metal parts of your boat’s engine. Severe corrosion can even lead to engine failure. This is why it’s important for you to be aware of the important role saltwater plays in accelerating this corrosion and degradation of your boat engine.

Why saltwater is more damaging than freshwater

Freshwater can indeed cause mild engine corrosion, but saltwater is far more damaging. This is because saltwater is a better conductor of electricity, which enhances the electrochemical reaction that causes corrosion. Furthermore, salt crystals can deposit in small crevices of the engine, inducing substantial degradation over time. This makes understanding the implications of saltwater on your engine even more significant.

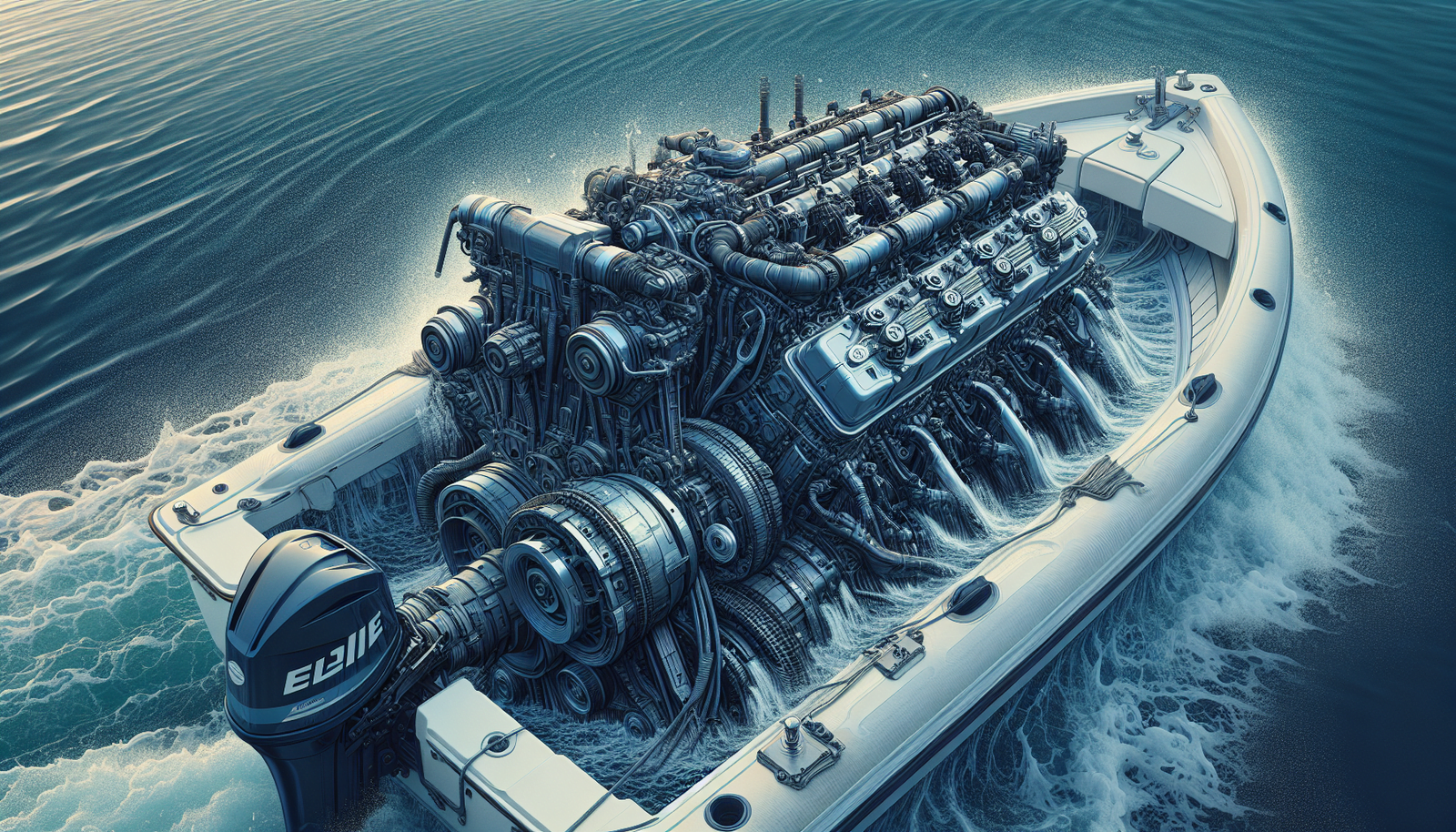

Choosing the Right Engine for Saltwater Use

As saltwater is significantly more corrosive than freshwater, it’s imperative to choose the right engine for saltwater usage.

Saltwater resistant engine materials

When considering an engine for saltwater use, look for materials like stainless steel, bronze or specialized composites that are resistant to saltwater corrosion. These materials can withstand extended exposure to saltwater without significant degradation, making them ideal engine components.

Optimizing engine performance in saltwater

To optimize your engine’s performance in saltwater, it’s recommended to use engines specifically designed for marine use. These engines are built with materials that offer enhanced resistance to saltwater corrosion, ensuring optimal performance and longevity.

Top engine brands for saltwater use

Many marine engine brands are renowned for their resistance against saltwater damage. Brands like Yamaha, Mercury and Evinrude consistently offer robust and reliable options. Consider your specific boating requirements and your budget when choosing an engine that suits your needs.

Rinsing the Engine After Saltwater Use

One of the most straightforward ways to limit the damage caused by saltwater corrosion is rinsing your engine meticulously after every use.

The importance of thorough rinsing

A thorough rinsing after each journey helps to wash away salt residues that deposit on your engine, restricting them from corroding the engine’s crucial components. Investing time in a thorough rinse doesn’t just mean great engine upkeep; it also translates into tangible savings in repair and replacement costs over time.

Step-by-step guide to rinsing a boat engine

Rinsing a boat engine involves several crucial steps, beginning with visually checking for salt deposits. Next, flush your engine using fresh, clean water. Ensure the water runs through all parts of the engine to wash off any residual salt. Finally, let your engine run for a few minutes to allow it to dry completely.

Optimal water temperature for engine rinse

While rinsing your boat engine, make sure the water temperature is lukewarm. Extreme cold or hot water can cause thermal shock, leading to potential engine damage.

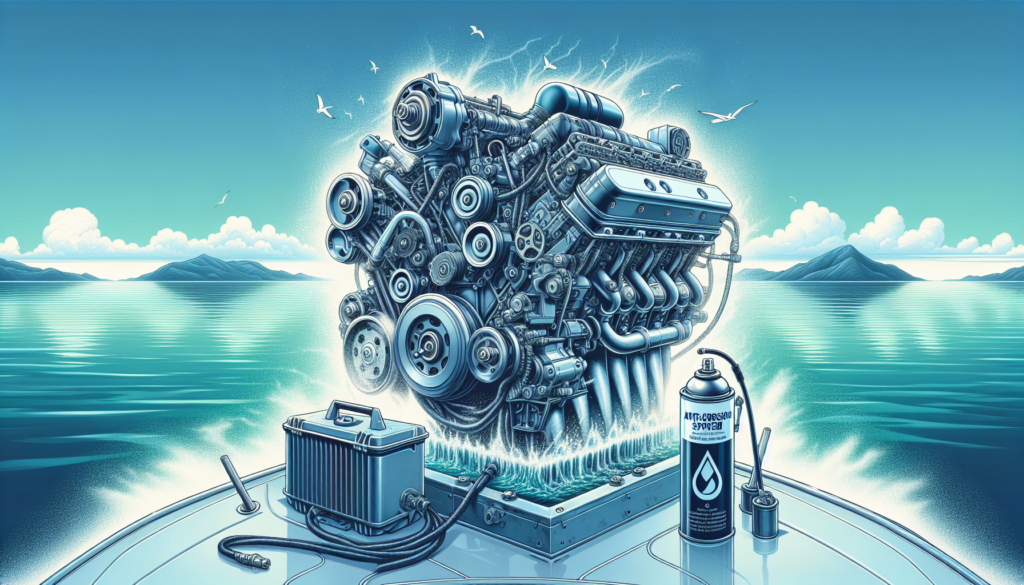

Corrosion Prevention Strategies

A comprehensive anti-corrosion strategy is instrumental in protecting your boat engine from saltwater damage. It pays off in the long run by saving on costly repairs and replacements.

Anti-corrosion sprays and lubricants

Anti-corrosion sprays and lubricants form a protective layer on your engine’s metal parts and prevent direct contact with salty water. This minimizes the chances of engine corrosion and extends engine life.

Use of anodes and cathodes

Installing sacrificial anodes on your boat’s engine can reduce saltwater corrosion considerably. These anodes get corroded instead of your engine parts, thus acting as a shield against saltwater.

Regular engine inspections for corrosion signs

Performing regular checks for signs of corrosion, such as rust or metal pitting, is the key to early detection and remediation. Prevention is always better than hefty repair costs, so be proactive about your engine’s health.

Periodic Engine Servicing

Regular servicing ensures your boat engine remains in peak operational condition and helps curb potential problems down the line.

Scheduling regular services

Stick to a regular servicing schedule for your boat’s engine. An expert mechanic can identify and rectify issues much earlier than you might notice them yourself.

In-between service checks

Regular services are crucial but don’t rely solely on them. It’s prudent to conduct self-checks in between service appointments, especially after prolonged saltwater use.

What a typical service should include

A typical service should include a thorough engine inspection, oil change, lubricating moving parts, changing filters, and checking and adjusting valve clearances. Featured checks should also include the fuel and cooling systems.

Replacing Engine Parts

Worn out or corroded parts can severely affect your engine’s performance and might even lead to an engine breakdown. It’s essential to monitor your engine parts regularly for any signs of trouble.

Identifying worn out engine parts

Regular inspection will help you spot signs of engine part wear and tear. A drastic or sudden reduction in your engine’s performance could be a sign of a worn-out part.

Criteria for replacing engine components

Factors to consider when deciding to replace engine components include the part’s age, its overall condition, or the frequency and severity of any issues it’s causing. If the cost of repairing a part is higher than the cost of replacing it, you should generally choose to replace.

Procuring authentic engine parts

When you need to replace any component, always make sure to buy authentic engine parts from trusted vendors. These parts come with a warranty, and they guarantee a proper fit and optimal performance.

Engine Oil Changes

Engine oil changes are among the most crucial aspects of engine maintenance. They ensure your boat engine runs smoothly and extends its life.

Recommended oil change intervals

You should change your boat engine’s oil every 50-100 hours of operation, or at least once a year. Following this schedule helps maintain the lubrication of your engine’s moving parts, reducing wear and tear and boosting engine life.

Choosing the right engine oil

Make sure to use marine-grade engine oil, which is explicitly designed for boat engines. It provides enhanced lubrication and corrosion resistance. Always refer to your engine’s user manual for the correct oil type and viscosity.

Steps to change engine oil properly

To change your engine oil, start by warming up the engine, but ensure it’s not too hot. Then, use an oil extractor to remove old oil, and replace the oil filter. Finally, fill up the engine with new oil. Remember to check the oil levels to ensure they are within the recommended range.

Fuel System Maintenance

A well-maintained fuel system is crucial for keeping your boat engine in optimal condition.

Maintenance of the fuel tank and lines

Regularly inspecting the fuel tank and lines for leaks or damage can help prevent major issues. A clean fuel system ensures that your engine receives a steady supply of fuel, which contributes to consistent performance.

Using fuel additives

Fuel additives help preserve fuel quality, especially during extended periods of storage. They also keep your fuel lines clean, contributing to smooth engine operation.

Preventing fuel contamination

Take preventative measures to avoid water or contaminants getting into your fuel system. Sealing the fuel tank correctly and using high-quality fuel filters can prevent contamination and consequential engine troubles.

Maintaining the Cooling System

The cooling system helps regulate your boat engine’s temperature, preventing it from overheating.

How the cooling system works

The cooling system circulates coolant (water or a mixture of water and antifreeze) around the engine, absorbing excess heat. This heat is then expelled via the exhaust system, ensuring your engine runs at a safe temperature.

Common cooling system problems

Common issues with the cooling system include a clogged radiator, leaky coolant hoses, faulty water pump, or a thermostat failure. Regular check-ups can help spot and fix these issues early before they become major problems.

Cooling system maintenance steps

Maintaining your cooling system involves regularly checking and topping up the coolant levels, inspecting the radiator for blockages, and checking the hoses for leaks. Also, routinely replace the coolant and thermostat to ensure optimum engine cooling.

Winterizing the Engine

If you live in a cold climate, it’s crucial to winterize your engine to protect it from freezing conditions.

Why winterization is important for saltwater boats

Winterization is especially important for saltwater boats. This is because any residual saltwater in the engine can freeze, causing potential engine failure or irreversible damage.

Steps for effective winterization

Effective winterization involves flushing the engine with freshwater to eliminate salt and water from the system. Next, apply antifreeze to the engine to protect it from freezing. Lastly, lubricate all moving parts to prevent corrosion during non-use in winter.

De-winterizing in spring

When warmer weather arrives, you’ll need to de-winterize your engine. This includes removing the antifreeze, replacing it with regular coolant, and inspecting all engine parts for potential issues before you start using the boat again. Stay on top of your boat engine’s maintenance, and it will ensure you enjoy smooth sailing!

[…] in high-quality engine components that have been designed to resist the corrosive effects of saltwater. These might be a bit pricey than the regular components, but they will serve you longer and […]