Are you looking to enhance the performance and efficiency of your boat engine? Look no further! In this ultimate guide, we will take you on a journey to explore the world of custom exhaust systems for boat engines. From understanding the benefits of upgrading to finding the right system for your specific needs, we’ve got you covered. Whether you’re a seasoned boat enthusiast or just starting to explore the possibilities, this comprehensive guide will provide you with all the information you need to make informed decisions and maximize the potential of your boat engine. So, let’s set sail and embark on this exhilarating adventure together!

1. Understanding Boat Engine Exhaust Systems

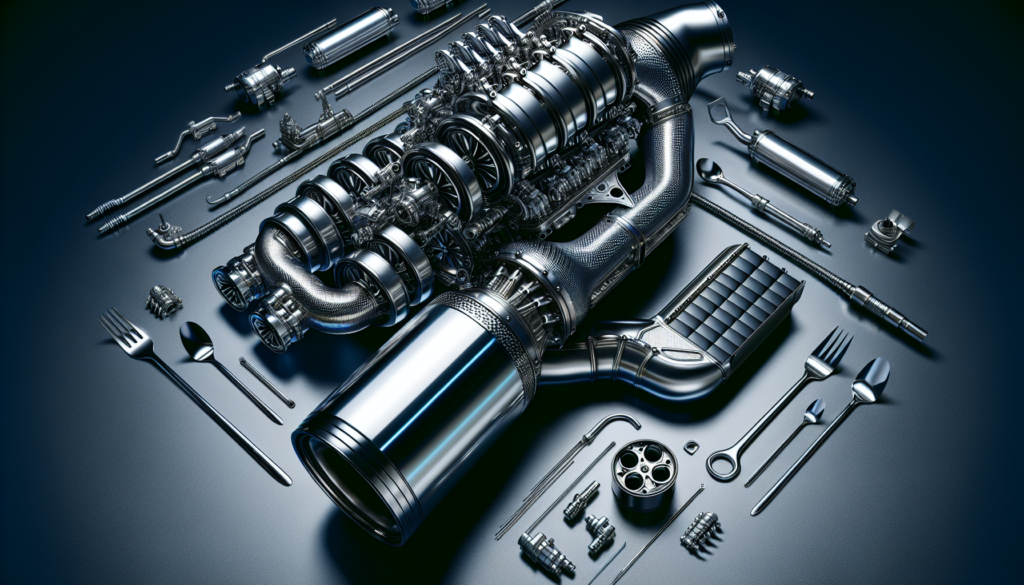

boat engine exhaust systems are an integral part of any watercraft. These systems play a crucial role in expelling harmful gases and minimizing noise produced by the engine. By understanding the different types of boat engine exhaust systems, the importance of custom exhaust systems, and the key components involved, you can make an informed decision when it comes to selecting the right exhaust system for your boat.

1.1 Types of Boat Engine Exhaust Systems

There are several types of boat engine exhaust systems available on the market. One common type is the wet exhaust system, where cooling water is mixed with the exhaust gases to reduce temperature and prevent overheating. Another type is the dry exhaust system, where the exhaust gases are released directly into the atmosphere without any mixing with water. Lastly, there are hybrid exhaust systems that combine both wet and dry elements.

1.2 Importance of Custom Exhaust Systems

Custom exhaust systems offer numerous benefits over stock exhaust systems. One of the primary advantages is that they can be tailored to the specific needs of your boat. Whether you’re looking to enhance performance, reduce noise, or achieve a certain aesthetic, a custom exhaust system allows you to have full control and customization options.

1.3 Key Components of a Custom Exhaust System

A custom exhaust system consists of several key components that work together to achieve optimal performance. These components include the exhaust manifold, which collects the exhaust gases from the engine cylinders, the exhaust pipes, which transport the gases to the rear of the boat, the mufflers, which reduce noise levels, and the exhaust tips, which provide the final touch to the system’s aesthetics.

2. Factors to Consider Before Choosing a Custom Exhaust System

Before diving into the process of selecting a custom exhaust system, there are several important factors you should consider. From the boat engine size and power to material selection, noise regulations, performance requirements, and cost considerations, each of these factors plays a crucial role in determining the most suitable exhaust system for your boat.

2.1 Boat Engine Size and Power

The size and power of your boat’s engine are significant factors that will influence the choice of a custom exhaust system. A larger engine may require a more robust system capable of handling higher exhaust gas volumes. Likewise, a more powerful engine may benefit from a custom exhaust system that promotes optimal airflow and maximizes engine efficiency.

2.2 Material Selection

choosing the right materials for your custom exhaust system is essential for durability and performance. Common materials used in boat exhaust systems include stainless steel, aluminum, fiberglass, and titanium. Each material offers its unique advantages, such as corrosion resistance, heat management capabilities, and weight considerations.

2.3 Noise Regulations and Restrictions

Boat noise regulations and restrictions vary from one area to another, and it’s crucial to ensure compliance with local laws. Before choosing a custom exhaust system, research the noise limitations and requirements in your boating location. Some systems incorporate specific features, such as silencers or noise dampening technology, to help reduce noise levels and meet regulatory standards.

2.4 Performance Requirements

Consider the performance requirements of your boat when selecting a custom exhaust system. If you’re looking to enhance engine power and acceleration, a performance exhaust system designed to maximize airflow and minimize backpressure may be the right choice. On the other hand, if you prioritize fuel efficiency, selecting an exhaust system that optimizes fuel-air mixture and reduces exhaust turbulence can help achieve better mileage.

2.5 Cost and Budget Considerations

Cost is another significant factor when it comes to selecting a custom exhaust system for a boat engine. Custom systems can vary in price depending on factors such as materials used, complexity of design, and branding. Setting a realistic budget based on your financial constraints is important to ensure you can make the right choice without compromising the overall quality of the exhaust system.

3. Types of Custom Exhaust Systems

Custom exhaust systems offer a wide range of options to suit different boat engine setups and personal preferences. Understanding the various types available can help you make an informed decision.

3.1 Straight Through Systems

Straight-through exhaust systems are known for their simplicity and efficiency. In this design, the exhaust gases flow in a straight path, promoting maximum airflow and reduced backpressure. These systems are often favored by performance enthusiasts who seek improved engine responsiveness and increased power.

3.2 Performance Systems

Performance exhaust systems are designed to enhance the overall performance of boat engines. They often incorporate features such as larger diameter exhaust pipes, tuned headers, and high-flow mufflers to maximize engine efficiency. These systems can significantly improve horsepower, torque, and acceleration, making them a popular choice for racing or high-performance boats.

3.3 Crossover Systems

Crossover exhaust systems aim to balance exhaust flow between engine banks in V-shaped or V6/V8 engines. They feature a crossover pipe that connects the two separate exhaust systems, allowing exhaust gases to pass from one bank to the other. This design promotes equalized pressure and improved scavenging, resulting in enhanced engine performance and reduced backpressure.

3.4 Diverters or Cutouts

Diverters or cutouts are powerful features that give you control over the exhaust flow. They allow you to switch between muffled or unmuffled exhaust modes, depending on your preference or specific performance requirements. By opening or closing the diverters, you can adjust the noise level and backpressure, tailoring the exhaust system to the desired sound and performance characteristics.

3.5 Combination Systems

Combination exhaust systems offer the flexibility to combine different features and designs, tailoring the exhaust system to your unique needs. These systems may incorporate elements from straight-through, performance, crossover, or diverter designs, allowing you to have the best of both worlds. The ability to customize and combine various features makes combination systems a versatile option for boat owners.

4. Materials Used in Custom Exhaust Systems

The choice of materials in a custom exhaust system can greatly impact its performance, durability, and resistance to corrosion. Here are the most common materials used in boat exhaust systems.

4.1 Stainless Steel

Stainless steel is widely regarded as one of the best materials for custom exhaust systems. It offers excellent corrosion resistance, strength, and longevity. Stainless steel exhaust systems can withstand harsh marine environments and resist the corrosive effects of saltwater, ensuring a longer lifespan for your boat’s exhaust system.

4.2 Aluminum

Aluminum is a lightweight material often used in custom exhaust systems. It offers good corrosion resistance and is highly conducive to heat dissipation. Aluminum exhaust systems are a popular choice for boats looking to reduce weight and improve fuel efficiency without compromising durability.

4.3 Fiberglass

Fiberglass is a composite material known for its excellent strength-to-weight ratio and resistance to corrosion. It is often used for high-performance boats and racing applications. Fiberglass exhaust systems offer the advantages of reduced weight and increased strength, making them a suitable choice for boats where weight savings and performance are prioritized.

4.4 Titanium

Titanium is an exceptional material in terms of strength, weight, and heat resistance. It is commonly used in high-performance applications where extreme durability and lightness are desired. Titanium exhaust systems offer superior performance and are capable of withstanding high temperatures and harsh conditions, making them ideal for high-speed boats and racing engines.

5. Design Considerations for Custom Exhaust Systems

Designing a custom exhaust system involves taking into account various factors to maximize performance and achieve desired outcomes. Here are some crucial design considerations to keep in mind.

5.1 Exhaust Pipe Diameter and Length

The diameter and length of the exhaust pipes directly influence the exhaust flow and overall performance. Larger diameter pipes allow for increased airflow, while shorter pipes may result in better response and acceleration. Determining the optimal pipe diameter and length is crucial for achieving the desired balance of power, torque, and engine efficiency.

5.2 Muffler Design

Mufflers play a significant role in noise reduction while also affecting performance. Selecting the right muffler design involves considering factors such as internal baffling, perforations, and chamber design. Mufflers can be tuned to enhance engine sound or minimize noise levels to meet regulatory requirements or personal preferences.

5.3 Backpressure

Backpressure is the resistance to exhaust gas flow created by the exhaust system. Custom exhaust systems should be designed to minimize backpressure while maintaining optimal engine performance. Too much backpressure can hinder exhaust gas flow, reducing power output, while too little backpressure can result in decreased low-end torque.

5.4 Heat Management

Heat management is crucial in custom exhaust system design. Engine exhaust gases can reach high temperatures, and it’s vital to prevent excessive heat buildup. Heat shields, insulation materials, and proper routing of the exhaust system can help manage temperatures, protecting surrounding components and ensuring optimal performance.

5.5 Aesthetics

Aesthetics are an important consideration for boat owners seeking to personalize their vessel. Custom exhaust systems often come with a variety of exhaust tip options, allowing for customization and matching the boat’s overall look and style. From sleek and polished stainless steel tips to more elaborate designs, the exhaust system can add flair to your boat’s appearance.

6. Installation Process for Custom Boat Engine Exhaust Systems

Installing a custom exhaust system for your boat engine requires careful planning and execution. Following a step-by-step installation process can help ensure a successful installation.

6.1 Safety Precautions

Before beginning the installation process, it’s important to prioritize safety. Make sure to wear protective gear, such as gloves and eye protection, and ensure the boat is in a stable and secure position. Disconnect the boat’s battery and allow the engine to cool down before beginning any work.

6.2 Removing the Old Exhaust System

Start by disconnecting and removing the old exhaust system from the boat. Carefully follow the manufacturer’s guidelines, using appropriate tools for fasteners and clamps. Take note of the old system’s routing, positioning, and attachment points, as these will help guide the installation of the new custom exhaust system.

6.3 Fitting the Custom Exhaust Components

Begin fitting the custom exhaust components based on the manufacturer’s instructions. This may involve securing the exhaust manifolds, attaching the exhaust pipes, and positioning any additional components such as mufflers or crossover pipes. Ensure proper alignment and fitment at each step to avoid leaks or interference with other boat components.

6.4 Securing and Sealing the Exhaust System

Once the custom exhaust components are in place, secure them using appropriate clamps or brackets. Ensure that all connection points are properly sealed to prevent leaks or air gaps. Follow the manufacturer’s recommendations for the correct torque specifications and installation techniques to achieve a secure and reliable exhaust system.

6.5 Testing and Inspecting the Installation

After the installation is complete, thoroughly inspect the custom exhaust system for any signs of misalignment or leaks. Reconnect the boat’s battery and carefully start the engine, checking for any unusual noises or vibrations. Monitor the exhaust system for any signs of leaking exhaust gases or other issues. If everything appears to be in order, proceed with a test run to ensure optimal performance.

7. Maintenance and Troubleshooting Tips for Custom Exhaust Systems

Proper maintenance and troubleshooting can help ensure the longevity and performance of your custom exhaust system. Follow these tips to keep your system in optimal condition.

7.1 Regular Inspections and Cleanings

Perform regular inspections of your custom exhaust system to identify any signs of wear, damage, or buildup. Check for corrosion, loose fittings, or leak points. Clean the exhaust system regularly to remove any dirt, debris, or salt deposits that may promote corrosion. Regular inspections and cleanings will help maintain the system’s performance and extend its lifespan.

7.2 Identifying and Fixing Leakage

If you notice any signs of exhaust gas leakage or unusual smells, promptly address these issues. Inspect the entire exhaust system for any cracks, loose connections, or damaged gaskets. Fix any leaks immediately to prevent potential hazards and ensure the system functions as intended.

7.3 Dealing with Corrosion and Rust

Corrosion and rust are common challenges in marine environments. Regularly inspect the exhaust system for any signs of corrosion, particularly around connections and joints. Address minor corrosion issues promptly by cleaning and applying a corrosion-resistant coating. For more severe cases, consider seeking professional assistance to repair or replace affected components.

7.4 Handling Noise Issues

If you experience unusual or excessive noise from your custom exhaust system, it’s important to identify the source and address it appropriately. Check for loose components, damaged mufflers, or faulty diverter valves. Adjustments or replacements may be necessary to resolve noise issues and maintain compliance with noise regulations.

7.5 Monitoring Exhaust Gas Temperatures

Regularly monitor exhaust gas temperatures to ensure proper engine performance and prevent overheating. Excessively high temperatures can damage exhaust components and lead to engine malfunctions. Use temperature monitoring devices or gauges to track exhaust gas temperatures and take necessary measures to keep them within safe limits.

8. Benefits of Custom Exhaust Systems for Boat Engines

Investing in a custom exhaust system for your boat engine can offer a range of benefits. Here are some advantages to consider.

8.1 Improved Engine Performance

Custom exhaust systems are designed to optimize airflow and reduce backpressure, leading to improved engine performance. By enhancing scavenging and reducing restrictions, these systems can increase horsepower, torque, and overall engine efficiency. The result is improved acceleration, throttle response, and overall performance.

8.2 Enhanced Fuel Efficiency

Some custom exhaust systems are specifically designed to optimize fuel-air mixture, resulting in improved fuel efficiency. By reducing restrictions and promoting better combustion, these systems can help increase mileage and reduce fuel consumption. This can be particularly beneficial for boaters who frequently embark on long journeys or have fuel-efficiency as a priority.

8.3 Better Sound and Noise Control

Custom exhaust systems allow you to tailor the sound of your boat engine, providing a personalized and enjoyable experience. Depending on your preferences, you can select mufflers and diverters that enhance the engine’s natural sound or reduce noise levels to meet regulatory requirements. Achieving the perfect balance of sound and noise control can greatly enhance your boating experience.

8.4 Increased Durability and Longevity

Opting for a custom exhaust system made from high-quality materials can improve its durability and longevity. Materials like stainless steel or titanium offer excellent corrosion resistance and are capable of withstanding harsh marine environments. Investing in a durable exhaust system reduces the risk of premature failure, saving you time and money in the long run.

8.5 Personalized Style and Aesthetics

A custom exhaust system allows you to add a touch of personal style to your boat. With various options for exhaust tips and designs, you can choose a system that complements and enhances the overall aesthetics of your vessel. From polished stainless steel tips to more eye-catching designs, a custom exhaust system can make your boat stand out from the crowd.

9. Legal and Environmental Considerations

When it comes to custom exhaust systems for boat engines, it’s essential to consider legal and environmental factors. Compliance with noise regulations, emission control standards, environmental impact assessments, and the necessary licensing and certification are crucial to avoid legal complications and minimize environmental impact.

9.1 Compliance with Noise Regulations

Boat noise regulations vary depending on the location and specific waterways. It is important to be aware of the local noise restrictions and ensure that your custom exhaust system meets or exceeds the necessary standards. Some areas have decibel limits that watercraft must adhere to, while others may have specific regulations for certain times of day or in sensitive areas such as residential zones or nature preserves.

9.2 Emission Control Standards

Emission control standards are in place to reduce the environmental impact of boat engines. When selecting a custom exhaust system, consider whether it meets the required emission standards. Some custom exhaust systems include additional features such as catalytic converters or particulate filters to help reduce harmful emissions. Ensuring compliance with emission control standards helps protect the environment and ensures smooth operation of your boat in restricted areas.

9.3 Environmental Impact Assessments

In some cases, larger boats or boats operating in environmentally sensitive areas may require an environmental impact assessment. These assessments evaluate the potential impact of a custom exhaust system on the surrounding ecosystem. They consider factors such as noise levels, emissions, and vibrations. It’s important to consult with local authorities or environmental agencies to determine whether an assessment is needed and comply with any regulations or restrictions that may be in place.

9.4 Licensing and Certification

When installing a custom exhaust system, it is essential to ensure that the system and its components meet relevant licensing and certification requirements. Depending on your location, certain certifications or approvals may be required to use the custom exhaust system legally. Verifying that the manufacturer or installer has the necessary certifications can help prevent legal issues and ensure the system is safe and compliant.

10. Recommended Custom Exhaust System Brands

When it comes to selecting a custom exhaust system for your boat engine, choosing a reputable brand is important. Here are five recommended custom exhaust system brands known for their quality and performance.

10.1 Brand A

Brand A has been a trusted name in the boating industry for years. Their custom exhaust systems offer a balance of performance, durability, and style. Brand A’s exhaust systems are known for their high-quality materials and precision engineering, making them a popular choice among boat enthusiasts.

10.2 Brand B

Brand B is synonymous with excellence and innovation. Their custom exhaust systems are designed to meet the specific needs and requirements of boat owners. With a focus on performance and fuel efficiency, Brand B’s exhaust systems are engineered to deliver optimal results while ensuring compliance with noise regulations and emission standards.

10.3 Brand C

Brand C is known for its cutting-edge designs and attention to detail. Their custom exhaust systems are crafted using the finest materials, offering exceptional durability and corrosion resistance. Brand C’s exhaust systems are renowned for their sleek aesthetics and ability to enhance both engine performance and the overall appearance of a boat.

10.4 Brand D

Brand D is a leader in the industry, offering a wide range of custom exhaust system options for boats of all sizes and types. Their exhaust systems are designed with performance in mind, delivering increased horsepower and torque. Brand D is committed to using high-quality materials and advanced manufacturing techniques to provide customers with reliable and long-lasting exhaust solutions.

10.5 Brand E

Brand E is a trusted name for boaters who prioritize both performance and environmental responsibility. Their custom exhaust systems are engineered to reduce emissions without compromising power or fuel efficiency. Brand E’s exhaust systems feature advanced technologies that help minimize noise levels while meeting or exceeding environmental regulations.

In conclusion, understanding the different types of boat engine exhaust systems, considering various factors before choosing a custom exhaust system, and being knowledgeable about the installation, maintenance, and benefits of custom exhaust systems is crucial for boat owners. By following this comprehensive guide, you can make an informed decision and select the right custom exhaust system that meets your specific needs, enhances your boat’s performance, and ensures compliance with legal and environmental standards.