Imagine cruising the open seas in your diesel-powered boat, the engine humming reliably as you soak up the sun and liberty of the endless ocean. You feel assured; you’re the captain of your ship. You earned that confidence through sweat, toil, and your sheer will to master the art of diesel boat engine maintenance. ‘The Ultimate Guide to Maintaining a Diesel Boat Engine’ is just what you need for this journey. With its practical instructions, insights from industry experts, and easy-to-follow advice, you are set to steer your marine life draft-free and future-proof. Keep your sails high and your engine higher when it comes to maintenance and efficiency with this knowledge-packed guide.

Understanding Diesel Boat Engines

In the world of marine propulsion, diesel engines play a very integral role. Whether you own a pleasure boat or a fishing vessel, understanding how a diesel boat engine works can greatly enhance your boating experience.

The basics of diesel boat engines

Diesel boat engines operate on the simple principle of internal combustion. The energy generated by this combustion process is what propels your boat forward. Unlike their gasoline counterparts, diesel engines use compression to ignite the fuel, which makes them a more reliable and safer option, especially in a marine environment.

Construct and capabilities

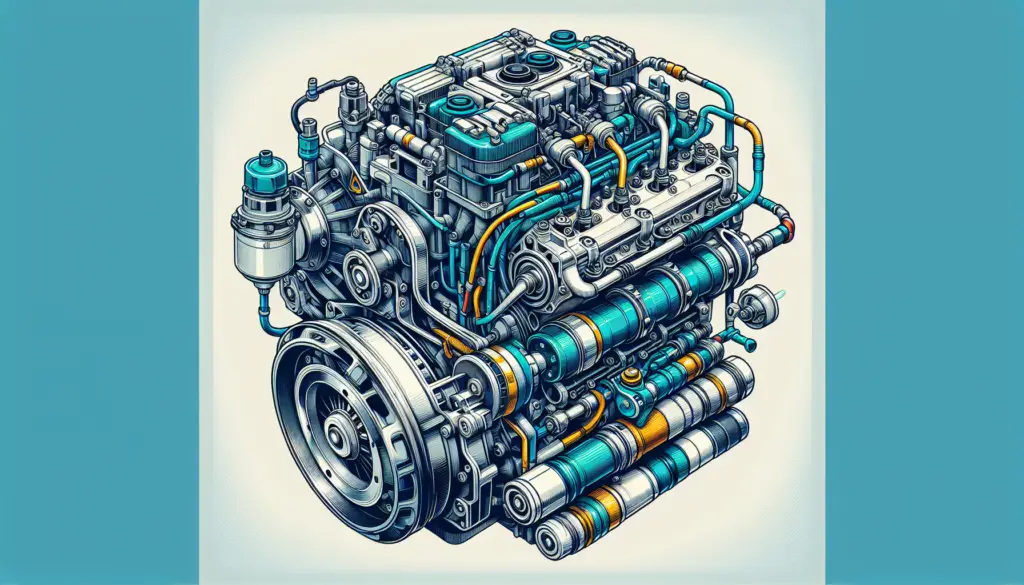

Diesel engines are constructed utilizing robust and hard-wearing materials which gives them inherent longevity. Their components such as the cylinders, pistons, crankshaft, and camshaft are all designed to withstand high operating pressures. They are also famously fuel-efficient and have impressive torque delivery, all crucial factors that count when you’re out on the sea.

Why choose diesel over gasoline

In terms of reliability, safety and economy, diesel engines tend to outperform gasoline engines. They have longer lifespans and lower operating costs due to their superior fuel economy. They generally don’t require ignition tune-ups and their fuel is less flammable, reducing the risk of fire onboard your vessel.

Features and Components of Diesel Engines

In order to maintain your diesel engine properly, you need to be familiar with its main components and their functions.

Engine coolant

Engine coolant, also known as antifreeze, is used to absorb heat from the engine and dissipate it through the radiator. Without the coolant, engines would overheat and fail rapidly, thus it’s essential to regularly check and maintain the coolant level.

Lubrication system

The lubrication system protects the moving parts inside your engine from undue wear and tear by providing a film of oil between them. It also aids in reducing friction, dispersing heat and improving efficiency.

Fuel injectors

Fuel injectors play a pivotal role in the engine’s fuel system. They spray fuel directly into the combustion chamber at precise moments, ensuring the optimal air-fuel mixture for combustion.

Pistons and cylinders

Pistons and cylinders are integral parts of the internal combustion process. The pistons compress the air-fuel mix in the cylinders, which is then ignited to generate power.

Exhaust and intake system

The exhaust and intake system allows fresh air to enter the engine and exhaust gases to leave. An effective, well-maintained air intake and exhaust system can dramatically improve your engine’s performance and fuel efficiency.

Diesel Boat Engine Maintenance Basics

Regular maintenance is the key to ensure your diesel engine runs smoothly and efficiently.

Importance of regular maintenance

Preventive maintenance can identify potential issues before they become major problems. It can help you avoid unexpected breakdowns, prolong the engine’s life and maintain its resale value.

General inspection routine for diesel engine

A standard inspection should include checking the oil and coolant levels, inspecting the fuel injectors, the air intake and the exhaust system and the condition of the belts and hoses. Regularly cleaning the engine is also recommended.

Tools needed for maintenance tasks

You will need basic tools such as a wrench set, screwdrivers, pliers, along with specific ones like oil filter wrenches and a good quality multimeter for electrical checks.

Sourcing reliable replacement parts

Always opt for good quality replacement parts that are compatible with your engine. Inferior parts can compromise your engine’s performance and may even lead to premature failure.

How to Check and Change Diesel Engine Oil

Engine oil is like the lifeblood of your diesel engine, ensuring everything runs smoothly.

Why engine oil is crucial for diesel engines

Engine oil reduces friction between moving parts, prevents overheating and helps to remove debris and sludge from the engine. If the engine oil is not regularly changed, the engine can suffer severe damage.

How often to change the diesel engine oil

Generally, diesel boat engine oil should be changed every 100 hours of operation or at least once a year. But this can vary, so always refer to your specific engine’s owner’s manual for the recommended oil change schedule.

Steps to change the diesel engine oil

To change your engine oil, firstly start the engine to warm the oil, it’ll make it easier to drain. Then using an oil extraction pump, drain the old oil. Replace the old oil filter with a new one, and refill with fresh engine oil. Ensure to precisely fill the engine to its proper operating level.

Maintaining the Lubrication System

The lubrication system plays a fundamental role in the longevity and efficiency of your diesel engine.

Understanding the importance of the lubrication system

The lubrication system maintains a protective oil film between moving parts, reducing friction, and wear. It helps to cool the engine by dispersing heat and even aids in keeping the insides of your engine clean.

Recommended lubricants

Always use marine-specific diesel engine oil of the right viscosity and API rating for your type of engine. Regular oil changes and using quality oil go a long way in extending your engine’s lifespan.

Steps to check and maintain the lubrication system

Firstly check the oil level, it should be within the optimal range marked on the dipstick. Monitor the oil pressure regularly. Low oil pressure can indicate major problems. Replace the oil filter at every oil change and regularly inspect shaft seals and gaskets for leaks.

Cleaning and Maintaining Fuel Injectors

Fuel injectors directly impact your engine’s performance, so it’s crucial to ensure they function properly.

The role of fuel injectors

Fuel injectors spray a precise amount of fuel into the combustion chamber. A smooth, mist-like spray pattern ensures the fuel burns efficiently.

Symptoms of clogged or faulty fuel injectors

Common symptoms include rough idling, power loss, poor fuel economy, and difficulty starting the engine. If you notice any of these signs, your fuel injectors might need attention.

How to clean and maintain fuel injectors

Cleaning fuel injectors involves removing, disassembling, cleaning, and inspecting them. It’s advisable to let trained professionals handle this task. Regularly using a good-quality fuel additive also helps keep your injectors in good working condition.

Cooling System Maintenance

The cooling system plays a crucial role in preventing your engine from overheating.

Understanding the cooling system

The cooling system in marine diesel engines can either be a raw water system or a closed-circuit freshwater system. The former uses seawater for cooling, while the latter uses coolant fluid; both are crucial to regulate the engine’s temperature.

Common concerns with the cooling system

Common issues include leaks, obstructions in the lines, fouling due to marine life and scale build-up. Irregularities in engine temperature or coolant loss are signs that the cooling system needs attention.

How to maintain the cooling system

Regularly check for leaks, clean the heat exchanger, and replace the coolant as recommended by the manufacturer. Regular inspection and servicing of the water pump, thermostat, and belts are also essential.

Air Intake and Exhaust System Maintenance

Your engine’s air intake and exhaust system directly impact its performance and efficiency.

Understanding air intake and exhaust system

The air intake system allows clean air into the engine for combustion, while the exhaust system helps to eject the burnt gases safely out of the engine. Both these components are vital for optimal engine performance and efficiency.

Common issues with air intake and exhaust

Issues can range from blockages in the air filters to leaks in the exhaust pipes and mufflers. These can result in reduced engine performance, increased fuel consumption, and potential safety risks.

How to maintain effective air intake and exhaust

Regularly clean or replace air filters to ensure that your engine gets clean air for combustion. Inspect the exhaust system for leaks or corrosion and address them promptly.

Overhauling Diesel Boat Engines

There comes a time in every diesel boat engine’s life when a simple repair job or tune-up does not suffice. This calls for an overhaul.

What constitutes an engine overhaul

An engine overhaul is a detailed inspection and restoration process that involves disassembling, cleaning, repairing, or replacing worn-out engine parts. It can greatly extend the life and performance of your engine.

When is it necessary to perform an overhaul

Regular maintenance can extend the need for an overhaul. However, indications like burning excessive oil, losing power, overheating regularly, or showing severe wear in internal parts may signal the need for an overhaul.

Steps to perform an engine overhaul

This is a very detailed and technical process which should ideally be left to the professionals. It involves disassembling the engine, inspecting and cleaning all parts, replacing worn-out parts, and finally, reassembling the engine. Strict adherence to the manufacturer’s guidelines is crucial during an overhaul.

Trouble Signs and How to Troubleshoot

Like any complex machinery, diesel engines can develop problems. Recognizing the early warning signs can help you identify and resolve issues before they escalate.

Identifying warning signs of engine problems

Signs can include difficulty in starting the engine, excessive smoke from the exhaust, unusual engine noise or vibration, drop in engine power, overheating or excessive fuel consumption.

Common problems and solutions

Overheating may indicate a faulty cooling system which can be rectified by servicing the system. Excessive exhaust smoke may indicate clogged fuel injectors that need cleaning or replacement. Loss of power could mean air filters need cleaning or replacing.

When to call in a professional

When the problem is beyond simple troubleshooting, calling in a professional is the best course of action. Major repairs or an overhaul should always be performed by a trained diesel mechanic. Remember, preventive maintenance is always better than costly repairs. Keep your diesel boat engine in top shape, and it’ll keep your boating trips smooth and enjoyable!