Get ready to immerse yourself in a full throttle journey as we explore the intricacies of boat engine fuel system components. You’ll be captivated as we unfurl the ins-and-outs of everything from fuel tanks to filters, injectors to pumps. Whether you’re a boating novice or a seasoned sailor, this comprehensive guide to understanding boat engine fuel system components will surely enrich your knowledge and enhance your boating experience. Hold on tight, as this is going to be one exhilarating journey!

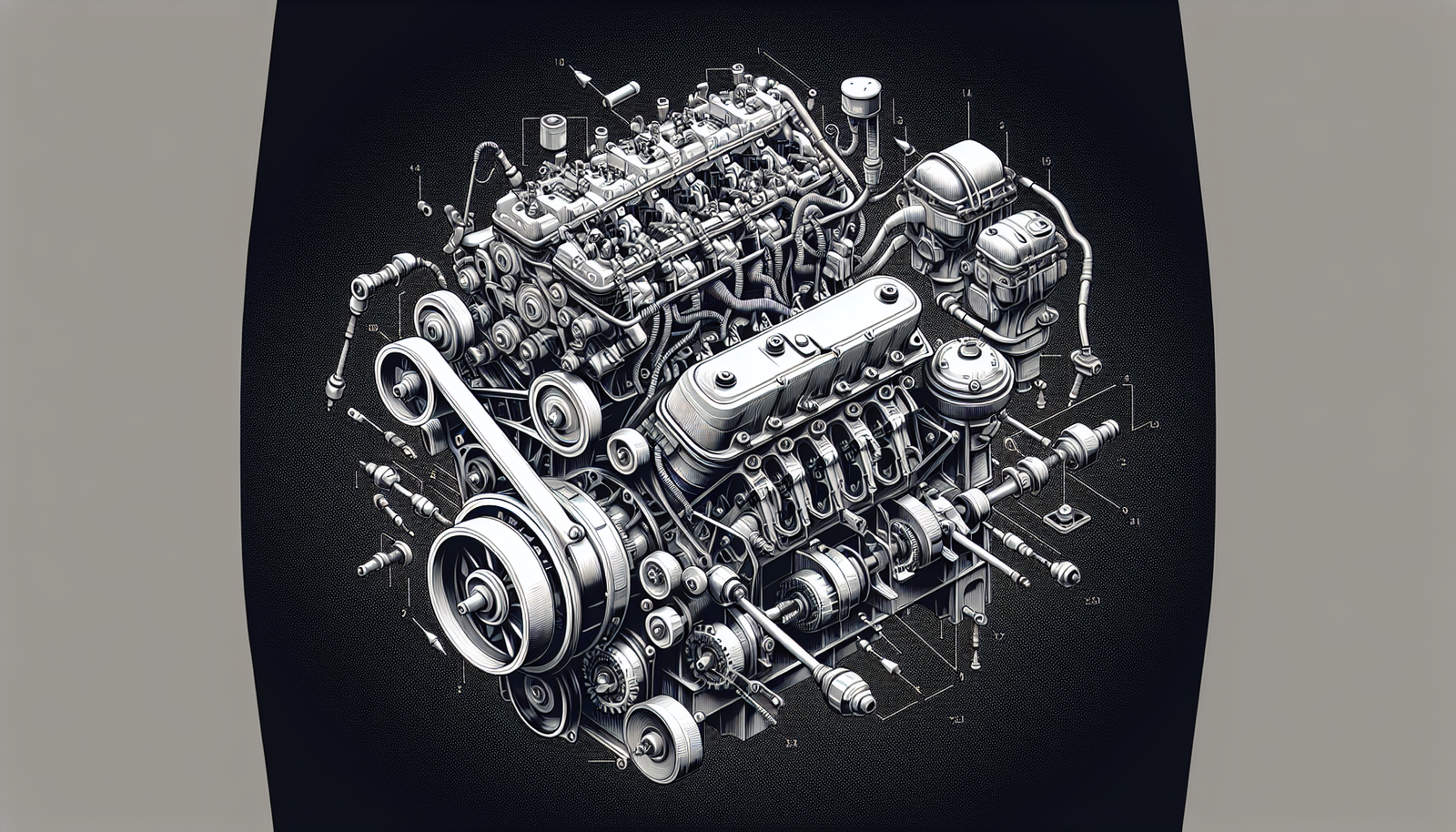

Understanding the Basics of Boat Engine Fuel Systems

Boat engine fuel systems are integral to the functionality and performance of your boat. Like any other engine, a boat engine needs a consistent supply of fuel to operate effectively. The fuel system is the vehicle that delivers this necessary energy source to the engine. Understanding the basics of boat engine fuel systems is an important aspect of boat ownership and maintenance.

Role of the Fuel System in a Boat Engine

The role of the fuel system in a boat engine is fundamentally to ensure the right amount of fuel is delivered to the engine at the correct time, and in the right condition. The fuel system transports the fuel from the tank, carries it through the fuel lines, filters it for any debris or water, and presents it to the engine to burn and create power. Without a properly functioning fuel system, your boat’s engine could become starved of fuel, resulting in poor performance or even engine failure.

Basic Components of a Boat Engine Fuel System

There are several key components of a boat engine fuel system you should be familiar with. These include: the fuel tank, which stores the boat’s supply of fuel; the fuel lines and fuel pump, which transport fuel from the tank to the engine; the fuel filter and water separator, which ensure only clean fuel enters the engine; the carburetor or fuel injectors, which combine the fuel with air to allow it to burn within the engine; the primer bulb, which aids in delivering fuel; and finally, the anti-siphon valve, which prevents fuel from inadvertently siphoning out of the tank.

Types of Marine Engine Fuel Systems

There are several types of marine engine fuel systems, each with its own advantages and disadvantages. These include carbureted fuel systems, fuel injected systems, and direct fuel injection (DFI) systems.

Carbureted Fuel Systems

Carbureted fuel systems are the oldest type of fuel system in boats and rely on a device called a carburetor to blend air and fuel for an internal combustion engine. Carburetors, while less efficient than newer technology, are simple and inexpensive, finding favor in older boat models.

Fuel Injected Systems

Fuel injected systems replace the carburetor with one or more fuel injectors. Injectors spray fuel directly into the intake manifold where it combines with air before entering the combustion chamber, leading to better fuel efficiency and power than a carbureted system.

Direct Fuel Injection (DFI) Systems

Direct Fuel Injection (DFI) systems are a type of fuel injection system that injects fuel directly into the cylinder, bypassing the intake manifold. This results in improved performance and fuel efficiency, but these systems can be more expensive and complex.

Fuel Tank

Purpose of the Fuel Tank

The fuel tank is the reservoir that stores the fuel needed for the operation of the boat engine. It forms the foundation of the fuel system and its size determines how far or long you can operate your boat without needing to refuel.

Different Types of Fuel Tanks

Fuel tanks come in a variety of materials, sizes and shapes to suit different boating requirements. The most common types include metal tanks (usually aluminum), polyethylene or plastic tanks, and bladder tanks. Each type has its pros and cons— for instance, metal tanks are generally more durable and resistant to puncture but can be susceptible to corrosion.

Maintaining and Inspecting the Fuel Tank

Maintaining and regularly inspecting your fuel tank is crucial to the longevity of your boat’s fuel system. Check for leaks, corrosion, and fuel contamination. Inspect the fuel vent, gauge, and fill cap to ensure they are sealed and functioning properly. Always clear any debris or water you find in the tank.

Fuel Lines and Hoses

Role of Fuel Lines and Hoses

Fuel lines and hoses play the important role of transporting fuel from the storage tank to the boat’s engine. They connect to various components within the system and without them, the fuel wouldn’t reach where it needs to be.

Types and Materials of Fuel Lines and Hoses

Fuel lines and hoses can be made of a variety of materials including rubber, steel or even plastic. The choice of material depends on the fuel type and the specific needs of the boat. For each type, there are specifications it must meet to ensure its durability and safety.

Troubleshooting Common Problems

Some common problems with fuel lines and hoses include leaks, cracks, and clogs. Regularly inspect your lines and hoses for any signs of these issues. Always replace damaged or aged fuel lines and hoses promptly to prevent fuel leaks and engine problems.

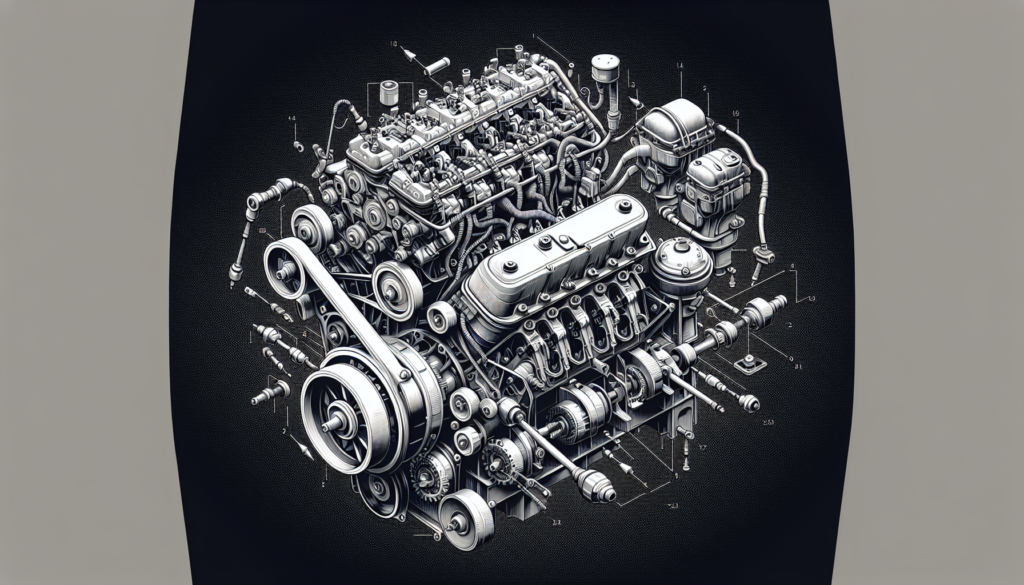

Fuel Pump

Operation Mechanism of the Fuel Pump

The fuel pump’s role is to deliver fuel from the fuel tank to the engine. It does this by using a pump mechanism – either a mechanical lever or an electric motor – to create pressure that pushes the fuel through the system.

Types of Fuel Pumps: Mechanical and Electric

There are generally two types of fuel pumps found in boat engines: mechanical and electric. Mechanical fuel pumps are driven by the engine’s camshaft, while electric fuel pumps use an electric motor. Both types have their advantages and disadvantages, with the main difference being the power source used to operate the pump.

Issues and Maintenance of a Fuel Pump

Common issues with fuel pumps include loss of power, failure to start, or uneven running. Regular maintenance of your fuel pump is necessary to keep it in good working condition; this includes keeping it clean and ensuring it is not clogged with debris.

Fuel Filter and Water Separator

Importance of Fuel Filters and Water Separators

Fuel filters and water separators play a crucial role in keeping your engine running smoothly by making sure only uncontaminated fuel reaches the engine. They filter out particles and separate water from the fuel.

How Fuel Filters and Water Separators Work

Fuel filters work by trapping particles in a porous material as the fuel flows through it, while water separators utilize the difference in density between water and fuel to separate any water in the system.

Maintenance and Replacement Guidelines

Both filters and separators require regular maintenance – this usually involves cleaning and replacing them periodically to maintain their effectiveness. Always refer to your engine’s manual to understand the specific maintenance schedule and protocol for your vessel.

Carburetor and Fuel Injectors

Difference between a Carburetor and Fuel Injectors

The main difference between a carburetor and fuel injectors lies in how they deliver fuel into the engine. A carburetor mixes fuel and air before delivering it into the engine, while fuel injectors spray fuel directly into the engine’s intake manifold or cylinders.

Functioning of Carburetor and Fuel Injectors

Regardless whether your boat’s engine uses a carburetor or fuel injectors, both parts serve one crucial purpose: blending fuel with air to form a burnable mixture, delivering it to the engine’s combustion chambers where it ignites to produce power.

Common Problems and Their Solutions

Common problems with carburetors and fuel injectors include clogging and incorrect fuel mixture. Regular maintenance and cleaning can help prevent these problems. For persistent issues, it may be necessary to replace the faulty part.

Primer Bulb

Purpose of a Primer Bulb in a Boat Engine Fuel System

The primer bulb in a boat engine fuel system serves to draw fuel from the fuel tank into the carburetor. By doing so, it enables the engine to start more easily.

How Primer Bulbs Work

Primer bulbs work by creating a vacuum that draws fuel into it when squeezed and then pushes the fuel out when released. This action primes the engine with a supply of fuel which aids in starting the engine.

Troubleshooting Primer Bulb Issues

Issues with the primer bulb can range from difficulty in squeezing the bulb, to the bulb not filling up with fuel, usually indicative of a clog or leak in the system. Solutions might involve replacing the primer bulb or checking the fuel lines and connections.

Anti-Siphon Valve

Role of the Anti-siphon Valve

The anti-siphon valve is a safety device found in boat engine fuel systems. Its primary role is to prevent fuel from inadvertently siphoning out from the tank in case a fuel line breaks or disconnects.

Understanding How an Anti-siphon Valve Works

The anti-siphon valve functions by only allowing fuel to flow in one direction – from the fuel tank towards the engine. When pressure from the fuel pump is applied, the valve opens, allowing fuel to pass through. However, when the pressure stops, the valve closes, preventing a back flow and accidental siphoning of fuel.

Detecting and Fixing Anti-siphon Valve Problems

Common issues with the anti-siphon valve include blockage from trapped debris and wear and tear from aging, which can lead to fuel supply issues. Regular inspection is necessary, and any issues should be promptly addressed, often requiring valve replacement.

Safety Measures in Handling Boat Engine Fuel Systems

Boat engine fuel systems are vital, but also potentially hazardous if not handled correctly. Understanding safety measures in handling these systems is crucial for every boater.

Essential Safety Precautions

Basic safety precautions include ensuring your engine is off when refueling, avoiding smoking or open flames nearby, regularly checking for leaks in the fuel system, and properly ventilating your vessel to avoid fuel vapor accumulation.

Emergency Procedures

In the event of a fuel leak or spill, knowing the emergency procedures is crucial. These typically involve shutting down the engine, activating the bilge blower, and using absorbent materials to clean up the spilled fuel.

Need for Regular Inspection and Maintenance

Regular inspection and maintenance of your boat’s engine fuel system is not just about keeping your boat running at peak performance – it’s also about safety. A well-maintained engine is less likely to have issues like fuel leaks or blockages, which could turn into significant safety hazards.

In conclusion, understanding your boat engine’s fuel system is a key part of responsible and safe boat ownership. From knowing the basics to understanding safety measures, every aspect of your fuel system is important to ensure your boating experience is safe and enjoyable.