You’re about to embark on a journey to decode boat engine intake manifold problems. This crucial component of your boat engine often encounters issues, ensuring smooth power delivery and performance. Think of it as the heart of your boat engine’s breathing system, and when it experiences problems, your engine gasps for air. The forthcoming article offers a comprehensive breakdown of these manifold issues and how to troubleshoot them efficiently while sailing along the beautiful horizons.

Understanding Boat Engine Intake Manifold

Understanding the function of an intake manifold

The intake manifold is a critical component in your boat’s engine. Its primary function is to evenly distribute the combustion mixture (air and fuel) to each intake port in the cylinder head. The even distribution is essential to optimize the engine’s performance, offering seamless power delivery and fuel efficiency. Essentially, you can think of the intake manifold as the bridge between the carburetor and the engine cylinders, making sure that everything gets the right mix it needs to work optimally.

Role of intake manifold in boat’s engine

Beyond the task of distributing the air-fuel mixture, the intake manifold also plays a crucial role in regulating the engine’s temperature. It accomplishes this by circulating coolant through the manifold via the engine block. By managing temperature and optimising distribution, the intake manifold directly affects the engine’s power output, running smoothness, fuel efficiency, and overall reliability.

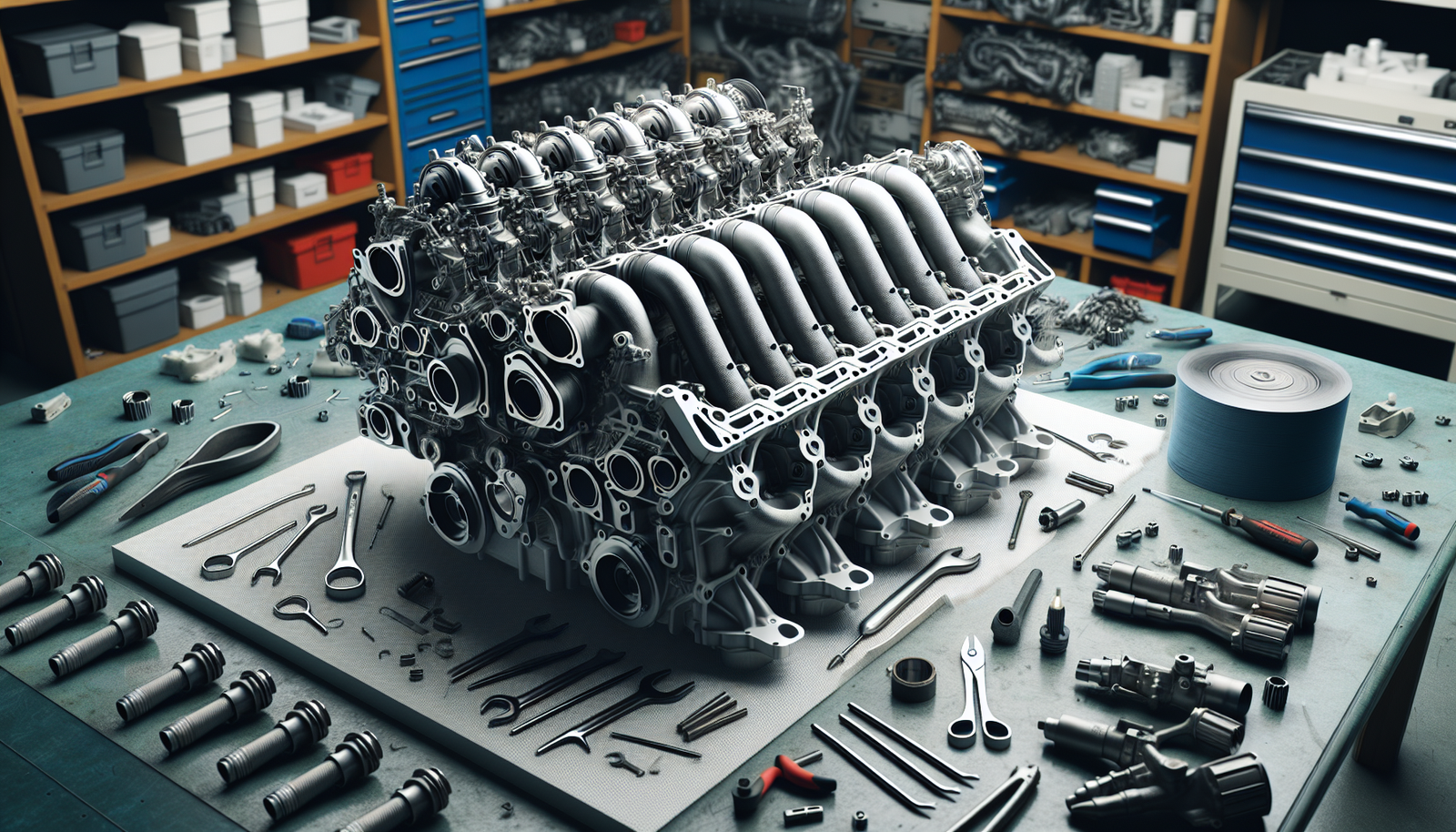

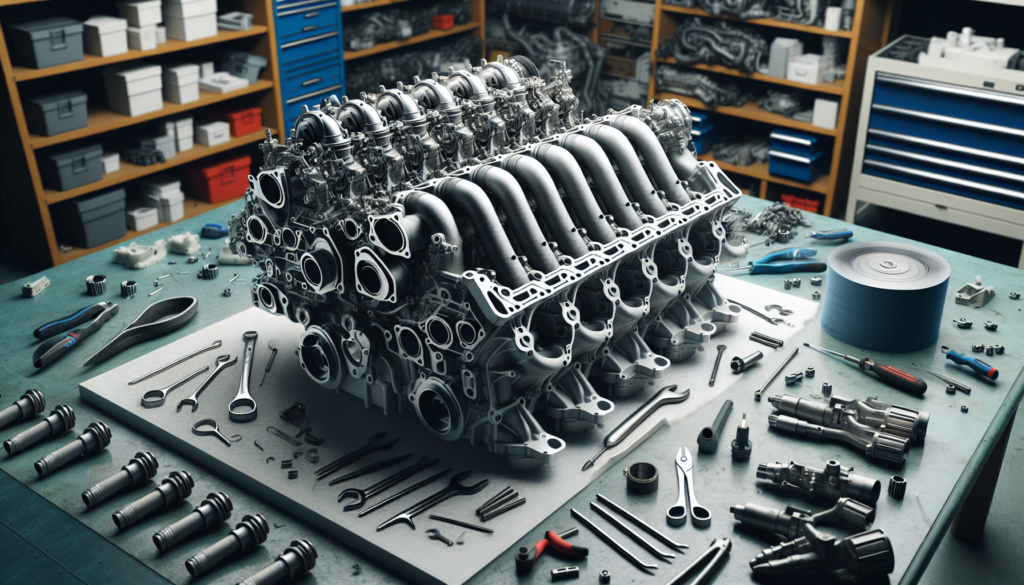

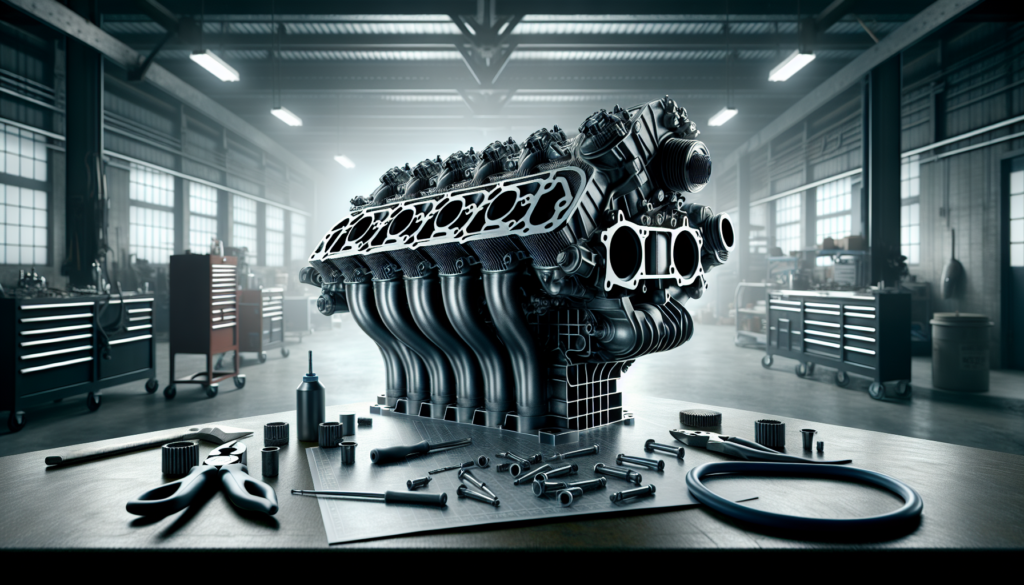

Construction and design of an intake manifold

The design and construction of an intake manifold can vary significantly, depending primarily on the type of engine. Most manifolds are made of aluminium or cast iron, although some modern boats use plastic for its lightweight properties. In terms of design, the manifold comprises intake runners (channels that lead to each cylinder), a plenum (the chamber where the air-fuel mixture collects before distribution), and mounting spaces for various sensors and components that support engine operation.

Common Manifold Problems

Overview of common manifold problems

Several common problems can affect the intake manifold. These include water intrusion, manifold leaks, manifold gasket failure, and carbon buildup, among others. Although these issues may vary in severity, they all negatively affect the engine’s performance and, if not addressed, can lead to severe engine damage.

Signs and symptoms of manifold issues

Keeping an eye out for signs of manifold issues can help you diagnose and address problems early. Common symptoms include the engine running rich (too much fuel and not enough air in the mixture), reduced fuel efficiency, poor engine performance, and overheating. In some cases, a check engine light may also come on, indicating potential issues with the intake manifold.

Impact of manifold problems on boat engine performance

Manifold problems can significantly impact the boat engine’s performance. For instance, a faulty intake manifold may lead to an incorrect air-fuel mixture, resulting in poor combustion and reduced power output. Additionally, leaks or cracks in the manifold can interrupt the effective circulation of coolant, potentially causing the engine to overheat. This not only reduces your boat’s efficiency but also shortens the lifespan of your engine.

Water Intrusion

Explaining water intrusion in intake manifold

Water intrusion refers to the entry of water into the intake manifold. In marine engines, this can occur due to waves, spray, or a faulty exhaust system. Whatever the cause, the presence of water in the intake manifold can interfere with the air-fuel mixture, causing serious issues such as misfires or hydrolock.

Causes of water intrusion

As mentioned, causes of water intrusion can vary but typically involve exposure to water in the marine environment or issues with other engine components. In some cases, a failure in the exhaust system can allow water to enter the intake manifold, particularly if the boat engine isn’t properly angled.

Effects of water intrusion on the manifold and engine

Water intrusion in the intake manifold can have severe effects on the engine. In minor cases, it may cause poor performance or misfires. However, if a substantial amount of water enters the cylinders, it could result in hydrolock, a condition where the engine can’t compress the water, leading to severe internal damage. It is necessary to address water intrusion promptly to prevent significant engine problems.

Manifold Leaks

Types of manifold leaks

There are two main types of intake manifold leaks: vacuum leaks and coolant leaks. Vacuum leaks occur when external air gets sucked into the intake manifold, disrupting the air-fuel balance. Coolant leaks, on the other hand, happen when coolant intended to cool the manifold escapes, potentially leading to engine overheating or coolant entering the engine oil.

Detecting manifold leaks

detecting manifold leaks can sometimes be a challenge. However, symptoms such as poor performance, rough idling, engine overheating, and coolant loss can all indicate a potential leak. On some occasions, you may also be able to visually identify a coolant leak on the exterior of the manifold or notice a sweet smell, indicative of leaking coolant.

Impact of leaks on manifold and engine performance

Manifold leaks can have a detrimental impact on both the manifold and engine performance. Vacuum leaks can cause a rich air-fuel mixture leading to poor efficiency and potential engine damage. Coolant leaks can result in overheating or even more severe issues if the coolant mixes with the engine oil.

Cracks in the Manifold

Identifying cracks in the manifold

Cracks in the manifold can often be visually identified, although they can sometimes be difficult to spot. If you’re experiencing symptoms such as a rough idle, reduced performance, or even a whistling noise from the engine, these could be signs of a cracked manifold. Regular inspections can help identify cracks at an early stage.

Understanding why cracks happen

Cracks in the manifold typically occur due to stress and heat exposure. Over time, the metal (or other material) of the manifold can weaken and crack. In boats, this is often compounded by the harsh marine environment, with factors such as saltwater corrosion and temperature fluctuations increasing the strain on the manifold.

Effect of cracks on intake manifold’s efficiency

Cracks can significantly compromise the intake manifold’s efficiency. They create an opening for air to enter, resulting in a lean air-fuel mixture. This can reduce engine power, increase fuel consumption, and potentially cause detonation – a damaging condition in which the air-fuel mixture ignites prematurely.

Carbon Buildup

What is carbon buildup in an intake manifold?

Carbon buildup refers to the accumulation of carbon deposits within the intake manifold. These deposits can form as a result of oil, fuel, and air forming a sticky residue on the manifold walls. Over time, this residue hardens into carbon deposits, narrowing the passage within the manifold.

Problems caused by carbon buildup

Carbon buildup can cause several problems for your boat engine. It can obstruct the flow of the air-fuel mixture, leading to poor performance and reduced fuel efficiency. In severe cases, the deposits can completely block the intake runner, causing the cylinder to run lean and potentially leading to engine damage.

Prevention and treatment of carbon buildup

Regular cleaning is the best way to prevent carbon buildup in the intake manifold. There are various cleaning agents available that can help break down the carbon deposits, allowing them to be flushed out of the system. In severe cases, it may be necessary to remove the manifold for a thorough cleaning or replacement.

Manifold Gasket Failure

Understanding manifold gasket and its role

The manifold gasket is a seal that sits between the intake manifold and the engine block. It is designed to ensure a tight seal, preventing leaks of air, fuel, and coolant. The gasket also helps reduce vibrations from the engine to the manifold, providing a smoother and quieter operation.

Signs of manifold gasket failure

A failing manifold gasket can present different symptoms, such as coolant loss, oil leaking into the manifold, or a rough engine idle. In some cases, a failed gasket will show visible damage or wear, although often the signs may be more subtle.

Impacts of gasket failure on the manifold and engine operation

Gasket failure can interfere with the engine’s operation and affect the manifold integrity. For instance, it may cause vacuum leaks, leading to a rich air-fuel mixture and consequent drop in engine performance. Coolant leaks due to a damaged gasket can also result in engine overheating. Furthermore, oil leaking into the manifold can cause carbon buildup, exacerbating the problems.

Troubleshooting Manifold Problems

Steps for diagnosing manifold problems

If you suspect manifold problems, the first step is to visually inspect for any visible issues, such as leaks or cracks. Look for signs of coolant or oil around the manifold area, or check for carbon buildup by removing the manifold and examining the inside. You can also use a diagnostic tool (like an engine diagnostic code reader) to check for specific error codes related to the intake manifold.

Use of professional diagnosis tools

Professional diagnosis tools, including diagnostic scanners or smoke machines, can be beneficial in diagnosing manifold problems. A diagnostic scanner can read engine codes to pinpoint errors, while a smoke machine can be used to find unseen leaks in the intake manifold by releasing smoke into the system and observing where the smoke escapes.

When to seek assistance from a mechanic

While some issues can be diagnosed and addressed by the boat owner, others may require professional expertise. If you’re unsure about the problem, if the issue persists despite your attempts to fix it, or if the required repairs are beyond your comfort level, it’s best to seek help from a professional mechanic.

Fixing Manifold Problems

Tips for fixing manifold leaks

Fixing manifold leaks generally involves sealing or replacing the affected area. If the leak is minor, sealants can sometimes provide a temporary solution. However, for more severe leaks or if the manifold is cracked, it will likely need to be replaced.

Repairing cracks in the manifold

When it comes to repairing cracks in the manifold, welding can sometimes be an effective solution. However, the effectiveness of such a repair can depend on the severity and location of the crack and the material of the manifold. For more serious cracks or those that are in complex locations, replacement may be the best solution.

Addressing carbon buildup and gasket failure

Carbon buildup can often be resolved by cleaning the manifold with a suitable cleaner or manually scraping the buildup off. If the buildup is severe, the manifold may need to be disassembled for thorough cleaning or replaced if damage has occurred. When it comes to gasket failure, replacement is typically the best course of action. Always ensure the new gasket is properly installed to prevent future issues.

Maintaining a Boat Engine Intake Manifold

Importance of regular manifold maintenance

Regular maintenance is key to maintaining your boat engine intake manifold’s efficiency and prolonging its lifespan. Maintenance reduces the likelihood of encountering manifold problems like carbon buildup, cracks, and leaks. By taking care of your manifold, you can ensure smoother engine operation, better fuel efficiency, and overall improved engine performance.

Basic maintenance tasks for the manifold

Basic manifold maintenance tasks can include regular cleaning, inspection for leaks and cracks, and checking the gasket’s condition. Use suitable cleaner to remove any early signs of carbon buildup and regularly check for potential leaks or cracks. Pay close attention to the gasket and replace if you notice any signs of wear or damage.

Professional maintenance services for manifolds

While you can perform basic maintenance tasks yourself, it’s beneficial to have your boat engine intake manifold checked by professional mechanics periodically. They can provide a more comprehensive inspection, ensuring all components are in good working condition, and handle any necessary repairs or replacements. Even if you’re diligent with your maintenance, professional help can catch any potential issues you might have missed and keep your manifold running efficiently.