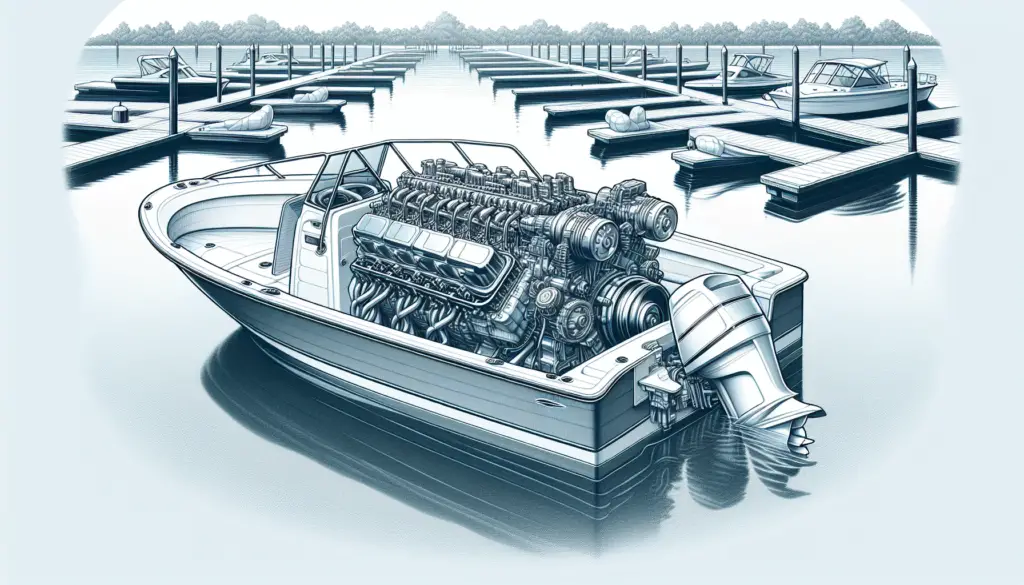

Ready to take your new boat out for a spin? Before you plan your first adventure, it’s crucial to understand how to properly break in your spanking new boat engine. By ensuring this process is done correctly, you’ll be setting the stage for your engine’s longevity and peak performance. This article lays out the essential steps to ensure that your new boat engine is broken in correctly, making those fun water outings more reliable and trouble-free than ever.

Understanding Boat Engine Break-In

Boat engines, like any other mechanical equipment, require an initial break-in period to reach optimal performance. This period is crucial because it allows internal parts of the engine, such as pistons and cylinders, to adjust to each other and begin functioning smoothly.

Importance of Engine Break-In

Engine breaking-in is a procedure that should not be undervalued. Proper break-in can have profound impacts on your engine’s life span, performance, and efficiency. It reduces friction, promotes smoother running, and minimizes internal wear and tear.

Expected Lifespan of a Properly Broken-In Engine

Typically, a properly broken-in engine can last anywhere between 1,500 to 2,000 hours of operation, depending on the make, model, and maintenance practices. However, some marine engines can even surpass these figures, provided that the break-in procedure was adequately followed and the engine is regularly maintained.

Analyzing Boat Engine Type

Before delving into the break-in process, it’s important to understand the type of boat engine you’re working with—specifically the distinction between two-stroke and four-stroke engines as both require different break-in procedures.

Two-Stroke vs. Four-Stroke Engines

Two-stroke engines complete a power cycle in two strokes, or one revolution of the crankshaft, while four-stroke engines require four strokes, or two crankshaft revolutions. Four stroke engines tend to be more efficient, but two-stroke engines are often lighter and simpler, making them popular in smaller boats and personal watercraft.

Manufacturer’s Procedures

No one knows the engine better than the people who built it. Always refer to the manufacturer’s manual, as it provides detailed recommendations and guidelines tailored for your specific engine type, be it two-stroke or four-stroke.

Initial Warm-Up Phase

The initial warm-up phase is the first step to the engine break-in process. It is essential to gradually increase the engine’s temperature before operating it under load.

Idling Your Engine

Start your engine and let it idle for a while. This warms it up slowly and ensures internal parts are adequately lubricated before moving on to higher strains. Be patient, rushing this stage can lead to long-term damage.

Monitoring the Temperature

Keep an eye on the engine’s temperature while it idles. You’re looking for a steady temperature that is within the manufacturer’s recommended range. Overheating can cause serious harm and should be avoided at all costs.

Short Running Times

Take things slow. During the break-in period, limit your running times, particularly at high speeds. Longer running times can be gradually introduced as the engine becomes accustomed to operation.

Engine Controls during Break-In

Understanding how to manage your throttle and adjusting your speed during the break-in period is crucial. Both play a significant role in ensuring your engine adjusts well to new operational conditions.

Understanding Throttle Positions

Awareness of throttle positions is key. Avoid running all-out—instead, operate your boat at varying low to moderate speeds. As a rule of thumb, keep the throttle position within half of full throttle during the break-in phase.

Importance of Varied Speeds

Operating at varied speeds promotes better seating of piston rings against the cylinder walls. This helps improve sealing, reducing the likelihood of leaks, blow-by, and oil consumption.

Avoiding High-Speed Operation

Refrain from high-speed operations during the break-in period. Pushing your boat to maximum speed too soon can cause handling stresses and increase the potential for damage to the engine’s internal components.

Optimizing Break-in Procedures per Engine Type

The break-in process changes depending on whether your engine is a two-stroke or a four-stroke.

Breaking In a Two-Stroke Outboard Engine

Two-stroke engines rely on a mixture of fuel and oil, meaning breaking in requires a more substantial amount of lubrication than a four-stroke engine — typically at a higher oil-gas ratio as instructed by the user manual.

Breaking In a Four-Stroke Outboard Engine

Four-stroke engines, on the other hand, have separate oil sumps, so you should follow manufacturer guidelines for choosing the correct oil grade and following the recommended fill procedure. Running periods should be shorter for four-strokes to allow for sufficient cooling periods.

Fuel and Lubrication during Break-In

fuel quality and lubrication can greatly influence the effectiveness of the break-in process.

Selecting the Appropriate Engine Oil

Ensure you are using the correct engine oil as recommended by the manufacturer. Poor-quality or unsuitable engine oil can hinder the break-in process and lead to premature wear or engine damage.

Engine Oil Change Interval

Remember to change the engine oil as directed by the manufacturer. This interval may be shorter during the break-in period due to the increased number of wear particles produced.

Fuel Quality Considerations

Use high-quality fuel from a reputable source throughout your boat’s life, but particularly during the break-in phase. Low-quality fuel can cause internal damage and may lead to engine performance problems.

Monitoring Engine Conditions

Vigilance is important during the break-in phase. Listen for unusual noises, keep an eye on temperature readings, and be aware of warning signs.

Possible Engine Noises

Unusual noises can be a sign of a problem. A constant knocking, pinging, or grinding noise, for example, likely signals an issue that should be investigated immediately.

Checking Engine Temperature

Keep close tabs on the engine’s temperature. If it becomes too hot, shut it off and give it a chance to cool down before resuming operation.

Identifying Warning Signs

Warning signs may include unexpected surging or loss of power, excessive oil usage, or excessive smoke. If you observe any of these issues, get your engine checked by a professional.

Maintenance Practices during Break-In

Regular maintenance isn’t just for the lifespan of your boat—it begins during the break-in period.

Changing Engine Oil and Filter

Ensure you change your engine oil and filter at intervals recommended by your manufacturer during the break-in. This helps remove debris and wear particles from the engine.

Inspecting Fuel and Vacuum Lines

Regularly inspect fuel and vacuum lines for cracks or wear that might cause air leaks or fuel seepage.

Cleaning and Replacing Spark Plugs

Regularly clean and inspect the spark plugs and replace them if they are worn or foul. This ensures consistent and efficient ignition.

Post Break-In Period

Once the break-in period is over, your boat is ready for a lifetime of normal use. But remember, regular maintenance is still crucial.

Understanding Normal Operation Range

After the break-in period, your engine should operate within a standard range under normal conditions. Refer to your owner’s manual for these specifications.

Scheduled Maintenance Check

Don’t overlook regular maintenance checks. Things like oil and filter changes, cleaning and checking spark plugs, and regular inspection of components are all crucial for optimal engine performance.

Performance Evaluation

After the break-in period, evaluate your boat’s performance. Compare it to the expected performance stated in the manufacturer’s manual. Any significant deviations could be a sign of an underlying issue and should be addressed.

Common Mistakes to Avoid during Break-In

There are common mistakes many boat owners make during the break-in period that can have long-term impacts on the engine’s performance and longevity.

Avoiding Prolonged Periods at Constant Speed

Running at the same speed for an extended time is not advisable during the break-in period. It’s best to vary your speed to help the engine components adjust properly.

Ignoring Engine Warning Signs

Dismissal or ignorance of engine warning signs can lead to major problems. Always listen to your boat. If something feels or sounds off, it’s a good idea to get it checked.

Skipping Initial Maintenance Checks

Ignoring initial maintenance checks can lead to higher costs and damaging problems down the line. Ensure you follow every maintenance guideline in your owner’s manual, especially during the break-in period.