Struggling with an overly-vibrating boat engine? It’s every boater’s nightmare, but don’t worry, we’re here to help. In this article, you’ll discover the possible culprits behind your boat engine’s excessive vibrations, from common issues like propeller damage to more complex problems such as driveline misalignment. Understanding what might be causing your engine distress is the first step in solving the mystery, giving you more time out on the water and less time in the repair shop.

Identifying Excessive Vibration in Boat Engines

Experiencing some level of vibration while your boat engine is running is normal, but excessive vibration can be an indication of a deeper issue. As a boat owner or operator, you need to be able to differentiate between normal operation vibrations and excessive vibrations. This will enable you to take the necessary actions to diagnose and fix any underlying issues before they escalate into more serious problems.

Understanding Normal Engine Operations

Normal boat engine operation comes with a certain level of vibration, which is expected due to the propulsion and engine mechanics. By getting acquainted with the normal running vibration, you will early enough notice any changes in the vibration levels. Exploring your boat as it sails different water conditions and speeds will give you insights into what normal responses feel like.

Signs of Excessive Vibration

Detecting excessive vibration starts with you, noticing uncommon changes in your boat’s usual behavior. For instance, if you notice a drastic increase in vibration whenever the engine runs or changes in the boat’s speed, it’s an indication that something may be off. Other signs may include irregular boat movement or noises and unsmooth sailing even in calm waters.

Causes of Excessive Vibration in Boat Engines

Several issues can cause excessive vibration in boat engines. It could be due to engine misalignment, propeller issues, or rough engine operation. It can also stem from unresolved maintenance issues or even overloading the boat.

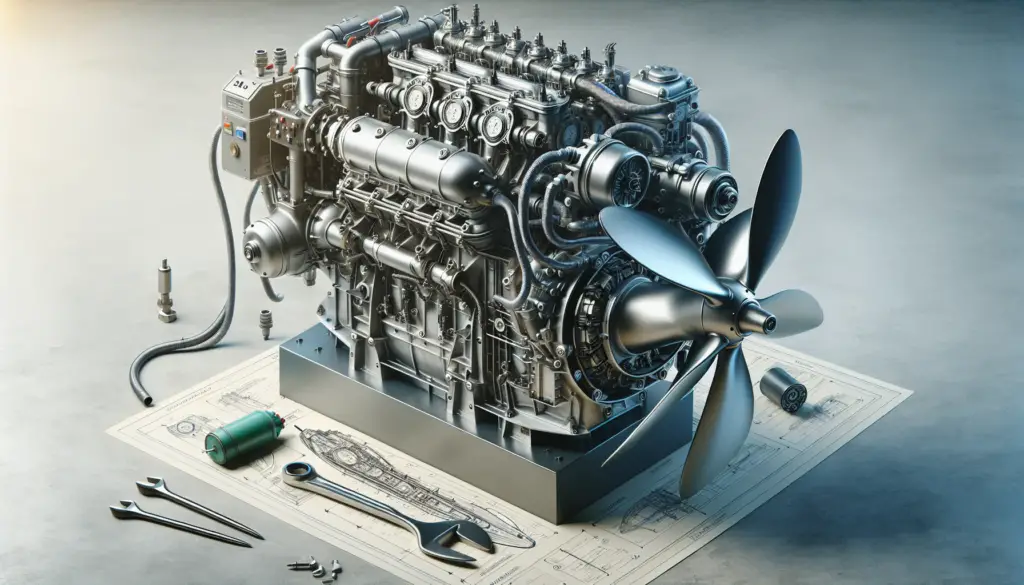

Engine Misalignment

When the engine and propeller shaft aren’t aligned properly, they can cause unnecessary stress and result in increased vibration. This misalignment may occur due to normal operation over time or improper installation.

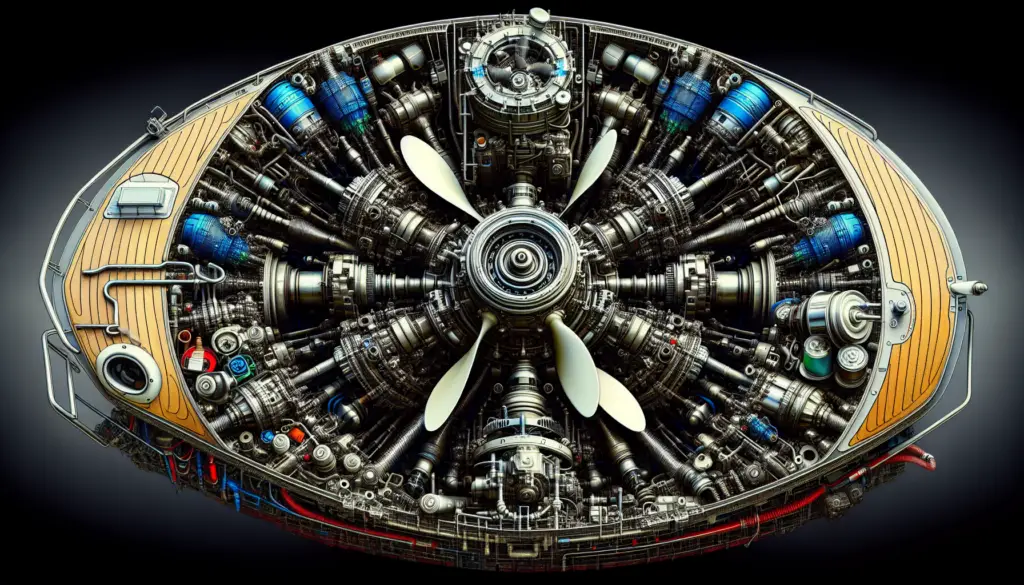

Damaged or Worn Out Propeller

The propeller is a critical component for smooth sailing. Over time, it could get worn out or damaged, leading to irregular turning. This irregular turning will cause vibrations because the engine has to work harder.

Rough Engine Operation

rough engine operation may also be a potential cause of excessive vibration. This involves any abnormality in the engine’s functioning, such as misfiring in the cylinders, which can lead to excessive shaking.

Engine Misalignment and Vibration

When an engine isn’t properly aligned with its shaft, it brings about a slew of problems, including excessive vibration. This can negatively affect your engine’s performance and the overall experience on the boat.

Effects of Misalignment on the Engine

Misalignment puts a lot of pressure on the engine and shaft, causing damage and excessive wear of various engine parts. This can lead to abnormal sounds, movement, and an unnecessary vibration increase during operation.

Identifying Misalignment Issues

Identifying engine misalignment might be quite challenging unless you’re an experienced mechanic. Barring any noticeable signs such as abnormal noises or excessive vibration, consider having a professional boat mechanic carry out periodical checks.

Fixing Misalignment Problems

Once misalignment is identified, it should be addressed by a trained mechanic. The realignment process requires expertise and precision to achieve the desired operation efficiency and stability.

Effects of a Damaged or Worn Out Propeller

A damaged or worn-out propeller can adversely affect your boat’s performance and comfort. Being a critical part of the propulsion system, any damages or wear must be addressed promptly.

How Propeller Damage Causes Vibration

When the propeller is damaged or worn out, it can no longer turn smoothly. This results in uneven propulsion, and the engine has to work harder, which in turn triggers excessive vibration.

Inspecting the Propeller for Damage

Regular propeller inspection for any signs of damage, including bends, chips, or eroded edges, can save you from a lot of potential trouble.

Replacing a Worn Out Propeller

Once damage or severe wear is identified on the propeller, the best course of action is to replace it. Doing so will restore your boat’s performance and reduce extra pressure on the engine.

Rough Engine Operation and Vibration

Rough engine operation is a common issue in boat engines that can lead to significant discomfort due to excessive vibration. Understanding why your engine operates roughly can help you address the problem effectively.

Causes of Rough Engine Operation

Rough engine operation can arise from several issues including a buildup of deposits in the cylinders, faulty fuel injectors, or worn-out engine parts.

Effects of Rough Operation on the Boat

An engine that isn’t operating smoothly can cause your boat to experience an uncomfortable level of vibration, which can also affect the boat’s stability.

Addressing Rough Engine Operation Issues

Resolving issues related to rough operation often require the insights of a seasoned mechanic. However, Regular maintenance, such as changing filters and timely repair or replacement of worn-out parts, can mitigate the problem.

Loose Parts Leading to Excessive Vibration

Loose engine parts can create a serious safety risk and also cause excessive vibration. Any loose parts in the engine compartment should be secured to avoid potential damage.

Dangers of Loose Parts in the Engine

Loose parts can cause damage by getting into moving components. They can also generate excessive vibration, which can lead to wear and tear, affecting performance and increasing the risk of engine failure.

Identifying Loose Parts

Perform regular inspections to check for any loose parts, especially after a repair job. Listen for any unusual sounds when the engine is running, as they can be indicative of loose parts vibrating against other components.

Tightening Loose Parts

Once you’ve identified loose parts, tightening them is the next step to take. Always ensure to tighten them according to recommended torque specifications to avoid over-tightening, which can cause additional issues.

Excessive Load and Engine Vibration

Overloading your boat can lead to many issues, including excessive engine vibration.

How Overload Causes Vibration

Excessive load causes the boat to sit lower in the water, which alters the shaft’s angle. This puts more strain on the engine as it attempts to maintain propulsion, resulting in excessive vibration.

Balancing Load on the Boat

Proper load management can help reduce excessive vibration. Always ensure you distribute weight evenly across the boat to maintain balance and prevent overloading.

Effects of Load Management on Vibration

Good load management not only enhances the stability and safety of your boat but also reduces strain on the engine, leading to less vibration and more comfortable rides.

Poor Maintenance and Vibration

Regular maintenance is crucial if you want to prevent problems like excessive engine vibration.

How Poor Maintenance leads to Vibration

Neglecting maintenance tasks such as oil changes, filter replacements, or wear inspection can lead to a buildup of issues causing the engine to operate less efficiently, leading to vibration.

Essential Maintenance Practices

Processes such as regular oil changes, filter replacements, routine inspections, and timely repair and replacement of worn-out parts are essential to maintaining a good boat engine condition.

Benefits of Regular Maintenance

Regular maintenance can help to prevent excessive engine vibration, increase engine efficiency, prolong the lifespan of your boat, and provide you with comfort and peace of mind while sailing.

Using Vibration Dampers to Reduce Vibration

Adding vibration dampers to your boat engine can help reduce vibration.

What are Vibration Dampers

Vibration dampers are devices designed to absorb the energy created by the vibrating boat engine, reducing the perceived vibration and making your rides more comfortable.

How to Install Vibration Dampers

Installation of vibration dampers should be performed by a skilled technician to ensure the correct fit and optimal functioning.

Effectiveness of Vibration Dampers in Reducing Vibration

Vibration dampers are quite effective in reducing vibration if correctly installed. However, it’s essential to remember they help manage vibration but do not resolve its root cause.

Preventing Excessive Vibration in Boat Engines

While addressing excessive vibration is crucial, prevention is always the best approach.

Regular Maintenance

Keep up with your boat’s maintenance schedule with oil changes, filter replacements, and regular checks to ensure every part is functioning as intended.

Proper Load Management

Always evenly distribute the load in your boat and avoid exceeding its recommended weight capacity to avoid undue strain on the engine.

Using Quality Parts for Repair and Replacement

Whenever parts need to be replaced, always opt for high-quality replacements. Doing this ensures that every component performs optimally, reducing the chances of increased vibration.